Hello

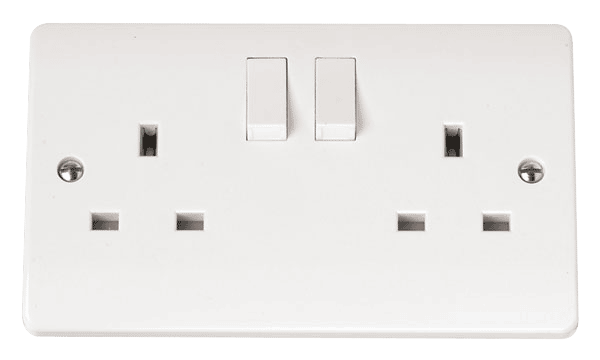

I'd like to add an outside socket and outside light from a double socket ring main.

I know I could add a FCU to the outside socket as a spur, then add another FCU for the light, but is that the best way to do it?

I was wondering how many put tubing through the cavity wall for the cable, and how many just feed the cable through the wall into the socket /FCU?

I'd like to add an outside socket and outside light from a double socket ring main.

I know I could add a FCU to the outside socket as a spur, then add another FCU for the light, but is that the best way to do it?

I was wondering how many put tubing through the cavity wall for the cable, and how many just feed the cable through the wall into the socket /FCU?