Hey all,

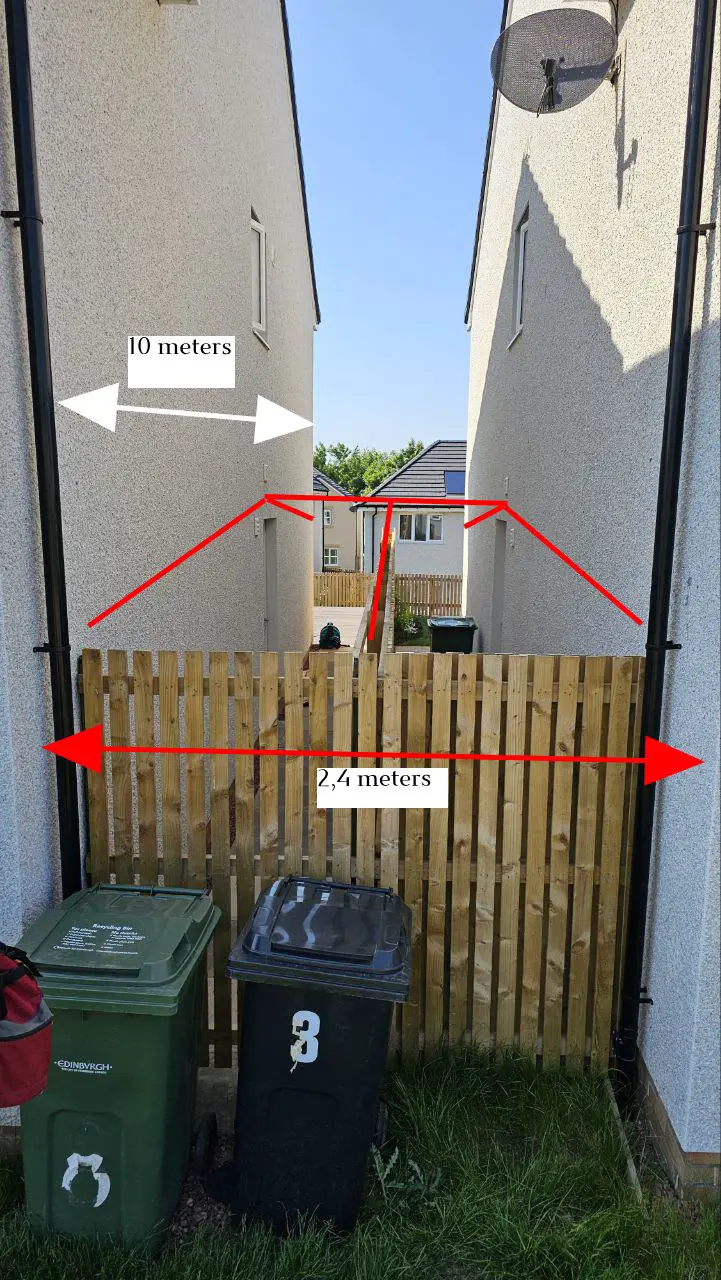

Me and my neighbour have decided to utilize the space between our two houses. I was thinking to build a roof covering the area, and use it as a storage space.

I am considering using polycarbonate sheets for the roof, shown on the picture in red.

Would be using 3 sheets per side, each 5.5m long and 0.8 m wide.

My main concern is how to add the fixings and the ridge once the sheets are in place. Is it possible to move over the polycarbonate roofing with a sliding board or lay over a ladder to reach the ridge/sides without damaging the polycarbonate sheets?

Or would it be better to use 1m by 2.4m sheets and put them "horizontally" from house to house? The concern I have is that water will end up in the glazing bars as they will act as a barrier.

Any advice would be greatly appreciated!

Me and my neighbour have decided to utilize the space between our two houses. I was thinking to build a roof covering the area, and use it as a storage space.

I am considering using polycarbonate sheets for the roof, shown on the picture in red.

Would be using 3 sheets per side, each 5.5m long and 0.8 m wide.

My main concern is how to add the fixings and the ridge once the sheets are in place. Is it possible to move over the polycarbonate roofing with a sliding board or lay over a ladder to reach the ridge/sides without damaging the polycarbonate sheets?

Or would it be better to use 1m by 2.4m sheets and put them "horizontally" from house to house? The concern I have is that water will end up in the glazing bars as they will act as a barrier.

Any advice would be greatly appreciated!