There's inbalance somewhere.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Warm Water From Cold Taps

- Thread starter endaxi

- Start date

Hi MM,Then I found this in a seperate thread...

Hi all,

Forgive my second attempt at explaining a problem but my first thread died an early death. I'll try to be more concise this time.

I have a 15 year old Megaflo CL210 fed from a gas boiler and after a partial drainage of the tank to fit a new kitchen tap now have hot water backflowing from the tank out to the cold water bathroom taps for about 30 seconds before they run cold again.

The cold water mains enters the airing cupboard and into an old type Heatrae Sadia 95 605 869 combination valve. When it leaves the valve it enters a T Piece where one side goes straight to the Megaflo inlet and the other to the cold water bathroom taps, I believe.

Should there be another PRV/NRV between the Megaflo inlet and the T piece to stop this backflow to the cold taps? I never had a problem before the cylinder drainage but a NRV between the tank inlet and the cold taps would stop the backflow, right?

Educating myself on the internet and found that the Megaflow should be serviced annually by G3 qualified engineer. Always get boiler serviced but never had the Megaflow serviced. I should get that done soonest.

Finally, I believe the Megaflo has an airgap inside. My system also has an expansion tank so I'm a bit confused with that.

Would it help to recharge the air gap? Nothing flowing through the tundish.

Grateful for any advice.

Thanks.

It makes it a lot easier to remotely diagnose if you'd given the info in THIS thread. Don't try to recharge the airgap, nor recharge the (red?) expansion vessel, they're OK as the system pressure holds up at 1.7 bar (this thread) and there's no discharge from the Megaflow CL210 (previous thread)

I am not convinced there's a parallel universe, so I'm goingto assume the two threads refer to the same thing.

Thanks for your replies and sorry I confused things by initiating two threads. I started the second thread as I thought this one was too confusing and I now realise I'm dealing with two separate problems.

The Honeywell for the HW is on a horizontal pipe with the electrical part on the side. It seems to function OK as it switches off when I switch the HW to OFF. It just stays open all the time the HW is ON and the pump keeps running even when the boiler switches off after the demand is met. I guess the BG engineer will fix that one easily enough tomorrow.

Hopefully he has a G3 ticket and can suss out the hot water backflowing from the Megaflo to the cold taps.

I won't try anything like re-charging lest I cause further problems. There may not even be a fault and just may be something has altered pressure-wise in the tank since it was partially drained. The stat on the boiler doesn't have temperature numbers on it but I've got it set to about 2/3 towards MAX.

As long as we're not in any immediate danger I'll wait until someone's had a look and if no joy I'll get the Megaflo serviced for the very first time and see what is recommended then.

Thanks to all who have replied so far. I'll be sure to post what ever is diagnosed to fix the issues.

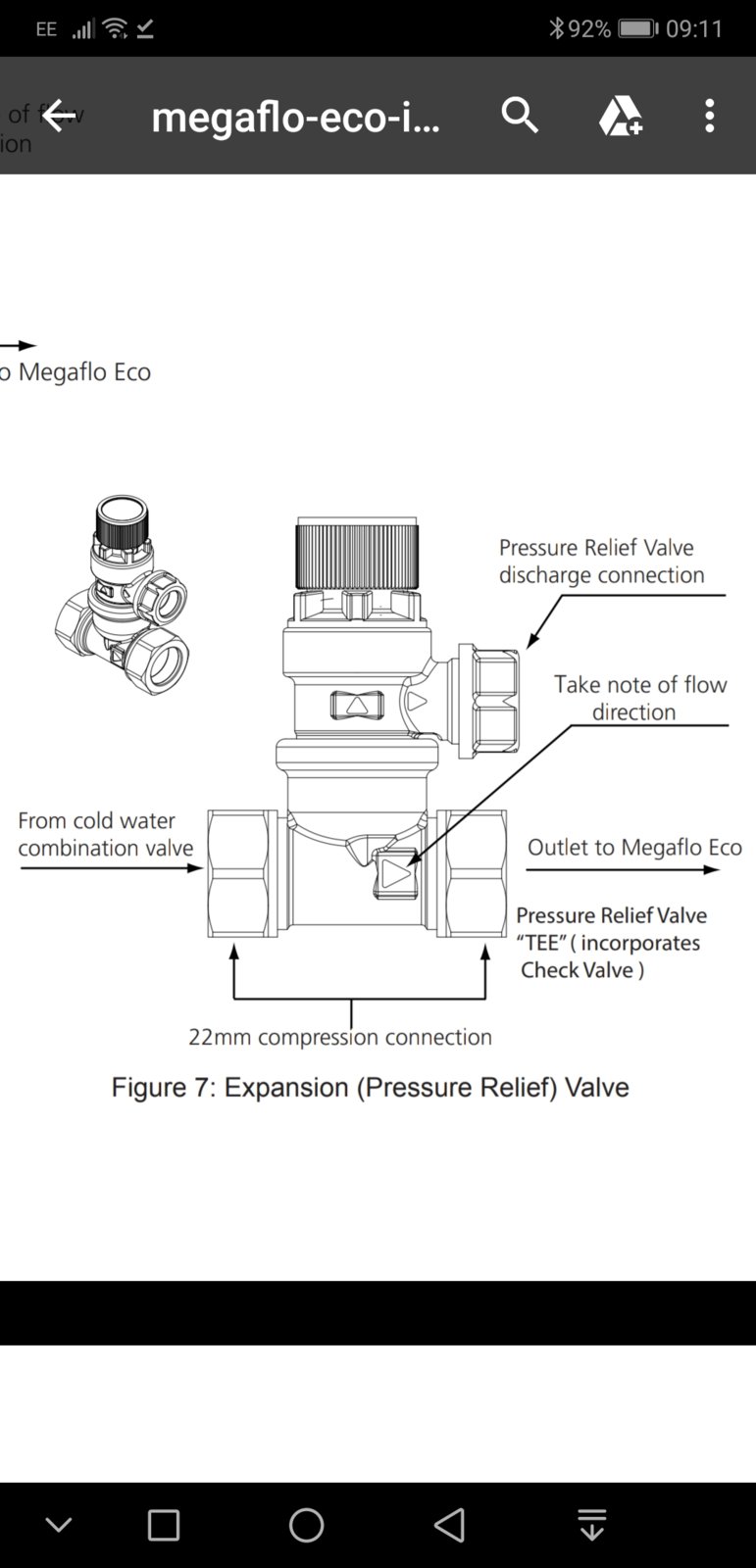

There's a schematic on page 11 here https://www.heatraesadia.com/-/medi...n-manuals/megaflo-eco-installation-manual.pdf that would cure my problem I think. I don't have the 8 bar relief valve/NRV on the cylinder inlet to prevent backflow as it is combined with the 3 bar prv before the T piece to the cold taps. That allows the backflow to the cold taps. Am I right?

As above. Check that the > is correctly oriented. See this page of the manual...

Hi all,

Thanks for the latest replies. Here's an update...

Re the last two posts by fezster and dilalio... this was my thought exactly but I found my Megaflo manual in a cupboard and the combination valve that is fitted was supplied with the cylinder and is fitted in the correct place and pointing the right way. The fitting instructions clearly state that the combination valve should be fitted after the drinking water taps (kitchen) and before the tee to the balanced cold (bathrooms) and Megaflo inlet. This ensures that expanded water doesn't flow to the drinking water although it seems it's acceptable for it to go to the balanced cold outlets for a short time. I don't tend to drink the bathroom tap water but my wife does and of course we all clean our teeth there.

Last night after a lot of time digesting the comments on this thread, in the manual and any other info I found on-line I realised the tank stat must be set to a higher temp than the boiler stat (I've only just found out where the tank stat is). I turned the boiler stat up nearer to max and the tank stat down to the mid position and that stopped the pump running continuously... no fault there then.

I then opened the cold tap in the bathroom and the water was cold for a bit then very hot for about 20-30 seconds then warm for about the same and then cold again. Not good. Obviously the tank temp was now higher than before due to cranking the boiler stat up and so had greater pressure too I suppose. I checked the temp at the hot tap with a meat thermometer and got 60 degrees so about right for a hot tap but not for a cold one.

BG engineer came this morning and was G3 unvented qualified. Told him the story and he said the combination valve was to the installation plan in the manual and the system shouldn't be tampered with by putting another PRV/check valve in. He said the guy who fitted the new kitchen tap would have been better turning the cold water off outside under the pavement as the position of the stopcock under the sink can affect the operation of the Megaflo. He appreciated that this was the only thing that had changed since everything worked ok.

He set the stopcock to a couple of turns out from closed and checked the flow from the utility room taps then adjusted the stopcock slightly to get the correct flow. He advised seeing how things go and if we still get excessive backflow to the cold taps from the expanded water to turn the stopcock down a quarter at a time and monitor again. He suggested the stopcock should be no less than about one full turn out from closed.

Still got the problem and now have stopcock at one turn out. Any feelings as to how far I can go with the stopcock?

Both the remedies of the boiler stat and the stopcock were suggested in the thread so thanks for the pointers in that direction which has certainly cured one problem and will hopefully cure the other.

Again, thanks very much to everyone for the help and I'll keep you posted about how it's going with the screwing down of the stopcock.

Just worried about how far to crank it down.... 3/4... 1/2?? Any opinions or experience of this?

Cheers.

Thanks for the latest replies. Here's an update...

Re the last two posts by fezster and dilalio... this was my thought exactly but I found my Megaflo manual in a cupboard and the combination valve that is fitted was supplied with the cylinder and is fitted in the correct place and pointing the right way. The fitting instructions clearly state that the combination valve should be fitted after the drinking water taps (kitchen) and before the tee to the balanced cold (bathrooms) and Megaflo inlet. This ensures that expanded water doesn't flow to the drinking water although it seems it's acceptable for it to go to the balanced cold outlets for a short time. I don't tend to drink the bathroom tap water but my wife does and of course we all clean our teeth there.

Last night after a lot of time digesting the comments on this thread, in the manual and any other info I found on-line I realised the tank stat must be set to a higher temp than the boiler stat (I've only just found out where the tank stat is). I turned the boiler stat up nearer to max and the tank stat down to the mid position and that stopped the pump running continuously... no fault there then.

I then opened the cold tap in the bathroom and the water was cold for a bit then very hot for about 20-30 seconds then warm for about the same and then cold again. Not good. Obviously the tank temp was now higher than before due to cranking the boiler stat up and so had greater pressure too I suppose. I checked the temp at the hot tap with a meat thermometer and got 60 degrees so about right for a hot tap but not for a cold one.

BG engineer came this morning and was G3 unvented qualified. Told him the story and he said the combination valve was to the installation plan in the manual and the system shouldn't be tampered with by putting another PRV/check valve in. He said the guy who fitted the new kitchen tap would have been better turning the cold water off outside under the pavement as the position of the stopcock under the sink can affect the operation of the Megaflo. He appreciated that this was the only thing that had changed since everything worked ok.

He set the stopcock to a couple of turns out from closed and checked the flow from the utility room taps then adjusted the stopcock slightly to get the correct flow. He advised seeing how things go and if we still get excessive backflow to the cold taps from the expanded water to turn the stopcock down a quarter at a time and monitor again. He suggested the stopcock should be no less than about one full turn out from closed.

Still got the problem and now have stopcock at one turn out. Any feelings as to how far I can go with the stopcock?

Both the remedies of the boiler stat and the stopcock were suggested in the thread so thanks for the pointers in that direction which has certainly cured one problem and will hopefully cure the other.

Again, thanks very much to everyone for the help and I'll keep you posted about how it's going with the screwing down of the stopcock.

Just worried about how far to crank it down.... 3/4... 1/2?? Any opinions or experience of this?

Cheers.

Just spoke to Heatrae Sadia tech support. They said that when the stopcock was turned off and hot water drained down it probably re-charged the air gap in the Megaflo and so the tank pressure has now increased a bit. They way my system was installed 15 years ago with the Combination Valve before the tee to the tank inlet and balanced cold would mean that I will get the backflow of expanded water to the bathroom cold taps when the water in the tank is hot and a cold tap is opened. This is not a problem as long as the backflowing water doesn't come out of the cold tap too hot. This inconvenience may subside over time, or even come and go.

He confirmed that the cure, should we want to, is to use the current installation procedure and split the combination valve so that it is as per the diagram in the link I put on the thread a few posts previously. That is, have the 3 bar reducing valve and check valve before the tee to the tank inlet and balanced cold and the 8 bar PRV and another check valve between the tank inlet and the tee piece with the PRV nearest to the tank of course. Same conclusion as we arrived at yesterday but not absolutely necessary unless the backflow is more than an inconvenience.

Just opened my stopcock to the two turns that gives me the correct flow from the utility taps as it didn't seem to make a difference to the backflow wherever it's set and I'll just leave things alone now I think.

There was never a fault in the first place it seems and things were just working as they're meant to. A questionable original installation design (I think) that's now been superseded by a new way of installing things. A great learning curve for me though and as usual you've all been most helpful.

Thanks.

He confirmed that the cure, should we want to, is to use the current installation procedure and split the combination valve so that it is as per the diagram in the link I put on the thread a few posts previously. That is, have the 3 bar reducing valve and check valve before the tee to the tank inlet and balanced cold and the 8 bar PRV and another check valve between the tank inlet and the tee piece with the PRV nearest to the tank of course. Same conclusion as we arrived at yesterday but not absolutely necessary unless the backflow is more than an inconvenience.

Just opened my stopcock to the two turns that gives me the correct flow from the utility taps as it didn't seem to make a difference to the backflow wherever it's set and I'll just leave things alone now I think.

There was never a fault in the first place it seems and things were just working as they're meant to. A questionable original installation design (I think) that's now been superseded by a new way of installing things. A great learning curve for me though and as usual you've all been most helpful.

Thanks.

Sorry posted in error, I hadn't seen the second page of the thread and what I wrote had been covered.

Stem... thanks for trying to give advice in any case. Hope you didn't type too much in your original reply.

Just for the record, even if only for me to refer back to...

Since I lowered the cylinder stat I have reports from the family that the hot water isn't hot enough and is running out too soon. I checked with my meat thermometer and was only getting 47 degrees at the tap. I turned the stat up a bit (very difficult to fine tune as it's tiny) and after the heat demand was satisfied I'm now getting 57 at the tap. Hopefully now hot enough in the tank to kill legionella (60 degrees) whilst not too hot at the tap so as to be scalding. Yep, I've been reading up on domestic water temps too.

Problem is of course when the boiler switches off and I open the cold tap the backflow is now pretty hot (not scalding but above comfortable) and lasts more than 30 seconds. I can't win.

Maybe I'll have to bite the bullet and employ a G3 engineer to move the 8 bar PRV from the Combination Valve Set to the cylinder inlet and put a check valve next to it. Or even just fit a whole lot of brand new valves in the required configuration.That would be the backflow problem completely sorted once and for all. I could get all the safety valves checked at the same time and hopefully the air gap correctly charged. I guess I'm looking at a few hundred quid here but at least everything should work properly and be safe.

One thing I noticed is that if I have the PRV moved it would probably be below the tundish so I guess that would have to be lowered as well.

The feeling I got from the BG engineer was that the Megaflo should be serviced every year when the boiler is serviced but that there is a reluctance to do this as playing with the safety valves and air gap unnecessarily can lead to problems, ie. leaks, that weren't there before.

All this because I had a new £75 kitchen tap fitted.

My nickname should be 'Lucky'... NOT!

Just for the record, even if only for me to refer back to...

Since I lowered the cylinder stat I have reports from the family that the hot water isn't hot enough and is running out too soon. I checked with my meat thermometer and was only getting 47 degrees at the tap. I turned the stat up a bit (very difficult to fine tune as it's tiny) and after the heat demand was satisfied I'm now getting 57 at the tap. Hopefully now hot enough in the tank to kill legionella (60 degrees) whilst not too hot at the tap so as to be scalding. Yep, I've been reading up on domestic water temps too.

Problem is of course when the boiler switches off and I open the cold tap the backflow is now pretty hot (not scalding but above comfortable) and lasts more than 30 seconds. I can't win.

Maybe I'll have to bite the bullet and employ a G3 engineer to move the 8 bar PRV from the Combination Valve Set to the cylinder inlet and put a check valve next to it. Or even just fit a whole lot of brand new valves in the required configuration.That would be the backflow problem completely sorted once and for all. I could get all the safety valves checked at the same time and hopefully the air gap correctly charged. I guess I'm looking at a few hundred quid here but at least everything should work properly and be safe.

One thing I noticed is that if I have the PRV moved it would probably be below the tundish so I guess that would have to be lowered as well.

The feeling I got from the BG engineer was that the Megaflo should be serviced every year when the boiler is serviced but that there is a reluctance to do this as playing with the safety valves and air gap unnecessarily can lead to problems, ie. leaks, that weren't there before.

All this because I had a new £75 kitchen tap fitted.

My nickname should be 'Lucky'... NOT!

All this because I had a new £75 kitchen tap fitted.

Have you tried isolating that new tap and monitoring any changes back to normality yet? It's an easy test to do, to rule the mixer out as being a problem!

To be honest it's got NRVs immediately before the flexis to the tap and there's been no hint of hot coming out of the cold side or even the cold pipe feeling warm. The problem only happens in the bathrooms and I can feel the hot water coming back through the cold inlet pipe to the Megaflo and out to the balanced cold as soon as a cold tap is opened in the bathroom.Have you tried isolating that new tap and monitoring any changes back to normality yet? It's an easy test to do, to rule the mixer out as being a problem!

I've been thinking it through again and I'm now convinced that the only thing it can be is the air gap in the Megaflo has changed as a result of the hot taps being run for so long when the stopcock was turned off under the sink.

I'm going to pluck up the courage to re-charge the air gap tomorrow if there's someone else around in the house to assist.

Wish me luck.

Ok, so having read my boiler and Megaflo user manuals I have set the thermostats (as per their instructions) to positions that represent 82 degrees at the boiler and 60 degrees in the Megaflo (direct and indirect). Hot water at the hot tap shows nudging 60 degrees using my un-calibrated meat thermometer. That's the legionella taken care of for sure then.

I then re-generated the air gap in the Megaflo for the first ever time (also as per their instructions) and the whole operation took about ten minutes. As a user I've done everything they recommend as far as I can see.

I switched on the hot water and waited until the cylinder demand was met and the boiler and pump switched off. I then opened the cold tap at the bathroom sink and after several seconds got hot water flowing for a good 30 seconds or so (so no change there then). I measured this long burst of hot water at 56 degrees so that's way beyond just being a nuisance.

So, back to the plan to remove the 8 bar PRV from the cold water combination valve (before the tee to the balanced cold) and presumably just blank-off the port it was fitted in. Then fit it to the Megaflo inlet (after the tee) with another check valve between the PRV and the tee to stop the backflow to the cold taps.

Sound like a plan?

I then re-generated the air gap in the Megaflo for the first ever time (also as per their instructions) and the whole operation took about ten minutes. As a user I've done everything they recommend as far as I can see.

I switched on the hot water and waited until the cylinder demand was met and the boiler and pump switched off. I then opened the cold tap at the bathroom sink and after several seconds got hot water flowing for a good 30 seconds or so (so no change there then). I measured this long burst of hot water at 56 degrees so that's way beyond just being a nuisance.

So, back to the plan to remove the 8 bar PRV from the cold water combination valve (before the tee to the balanced cold) and presumably just blank-off the port it was fitted in. Then fit it to the Megaflo inlet (after the tee) with another check valve between the PRV and the tee to stop the backflow to the cold taps.

Sound like a plan?

- Joined

- 26 Aug 2016

- Messages

- 6,830

- Reaction score

- 1,009

- Country

Sorry if it's already covered in the thread, but if you or a g3 engineer put an nrv between the cylinder and the cold taps in the bathroom, they will no longer be balanced pressure at all times, they will only be balanced when the pressure reducing valve is open.

This would probably only affect the first seconds of a shower and is probably better than higher pressure hot from the cold tap.

This would probably only affect the first seconds of a shower and is probably better than higher pressure hot from the cold tap.

Thanks for the input John. You're correct in what you say. When I spoke to Megaflo technical help they said I could move the 8 bar PRV to between the tank inlet and the cold bathroom taps with a NRV as per the current installation design and that would cure my problem. The slight downside is an initial surge at a higher pressure when a hot tap is opened. The current design of the valve positions in the cold water supply is the lesser of two evils when compared to what I currently have as far as I can see.Sorry if it's already covered in the thread, but if you or a g3 engineer put an nrv between the cylinder and the cold taps in the bathroom, they will no longer be balanced pressure at all times, they will only be balanced when the pressure reducing valve is open.

This would probably only affect the first seconds of a shower and is probably better than higher pressure hot from the cold tap.

See my link at post number 18 above for current design.

First I have to apologise for banging on about this but whereas I think I've accepted a solution for this problem by altering the design of the not-so-perfect system I can't get it out of my head that the hot and cold water worked fine before the tank was drained down.

I'm wondering if the floating baffle that I was recently educated about on another thread has got stuck on the dip tube and now means the water in the tank gets to a higher than normal pressure as it can't rise to compress the air bubble, but not quite reach the 8 bar that would show a drip in the tundish. If so, perhaps an external expansion vessel would be the better cure. Would re-positioning the 8 bar PRV and installing another NRV just mask the problem but deal with the symptoms nonetheless? Does it matter which route I take?

Furthermore in this can of worms is the siting of the tundish. If the PRV is moved it will be more than 600mm of pipe away from the tundish and so contravene the latest G3 regs apparently. I have three PRV discharge pipes going to the tundish and all are at least 1 metre of pipework away. Where it may be ok to leave them as they are, if a G3 engineer has to make some alterations then surely they would have to leave things in compliance.

Another phone call to Megaflo I think with a list of questions, but if anyone can shed any light on the above then please feel free to do so.

Thanks as usual.

My brain hurts.

I'm wondering if the floating baffle that I was recently educated about on another thread has got stuck on the dip tube and now means the water in the tank gets to a higher than normal pressure as it can't rise to compress the air bubble, but not quite reach the 8 bar that would show a drip in the tundish. If so, perhaps an external expansion vessel would be the better cure. Would re-positioning the 8 bar PRV and installing another NRV just mask the problem but deal with the symptoms nonetheless? Does it matter which route I take?

Furthermore in this can of worms is the siting of the tundish. If the PRV is moved it will be more than 600mm of pipe away from the tundish and so contravene the latest G3 regs apparently. I have three PRV discharge pipes going to the tundish and all are at least 1 metre of pipework away. Where it may be ok to leave them as they are, if a G3 engineer has to make some alterations then surely they would have to leave things in compliance.

Another phone call to Megaflo I think with a list of questions, but if anyone can shed any light on the above then please feel free to do so.

Thanks as usual.

My brain hurts.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 2

- Views

- 5K

- Replies

- 2

- Views

- 2K

- Replies

- 2

- Views

- 1K