I'm a retired electronics engineer. I like data ...

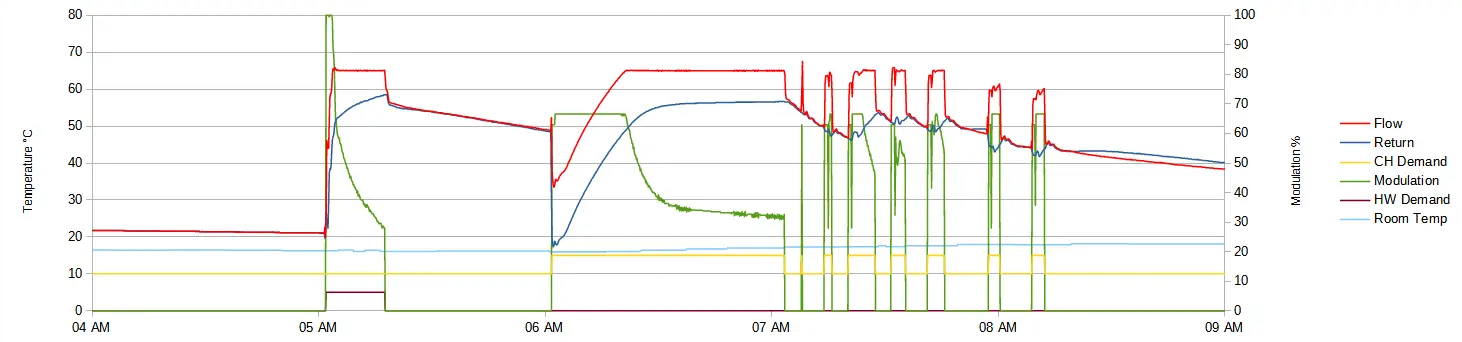

The room temperature is collected from the VRT392f every 10 seconds. Here is an expanded graph of the central heating operation:

View attachment 296699

The room thermostat is set for 18degC so it seems obvious to me that the boiler will keep supplying heat until that temperature is reached.

Mike

I'm also (was invloved, retired now) a multi award wining embedded designer of 20 years plus commercial development with my expertise being in RF network communications so I'm one for keeping data packets simple and meaningful as I an ultra low power kinda guy. ps my boiler interface uses the Ti CC3200.

So in order to raise your room temp by 1 degree, I see that it took 1 hour to do this and I can see that the boiler kicked in/out 6 times, with burn times much longer that pump run times (just circulating the water).

how much gas did you consume doing it this way? What was the outside temp? a staring point of 17 degree is not cold by any stretch...

What can I do with the data? What do you do with it?

I have around 736m3 to heat. Its over 5 levels and I use 15 rads. The boiler is rated 24kw. None of the rads have TRV's, I have no heating zones and no room thermostats.

I have a constant 16 degree room temp @ 50% humidity (in every room in the property) which we find comfortable

I achieve this by using a flow temp of max 35 degrees and the heating runs 24/7.

When its really cold (in the - range outside) I need to take it to 18 degrees (above which it becomes too warm)

I have 2 options of achieving this which is either increase flow temp to 50 degrees for a few hours or set the boiler to take over in auto mode (starts using air intake temp samples every 15 minutes) and compares heat gain in the rooms by measuring return temp. Auto mode I find is best left switched on to work best at times when day temps day by day vary (as we have now)

So having mapped the home, collected the data, I created an understanding of the property and then experimented with controlled intervention to achieve desired outcomes.

The data did its job so I don't need it any more.

ps have you considered running proxmox and puting everything in one place?