D

DAJ

I am in the process of renovatiing a 4 bedroom house. The project has been running for 3 years now, we are on a limited budget and 99% of the plumbing, electrics, building work etc. have been carried out by myself (hence 3 years!). So far, we have made a loft conversion with 3 bedrooms, built a purpose built 10 person cinema with 10' fixed screen and a state of the art bathroom.

BUT I am now about to embark on the kitchen which involves taking out a wall where a window is currently sited. The window is on the first floor of a 3 storey building (G, 1 & 2) and is around 1.8m wide (the window, not the building lol). I need to fit a 3m bio-fold door in it's place which will open onto a large balcony, yet to be built.

The intention is to make the reveal, then fabricate the bottom and fit a cheap softwood window until such time as the kitchen is completed. Then, when the balcony has been erected, remove the window and fabrication, and install the bio-fold door.

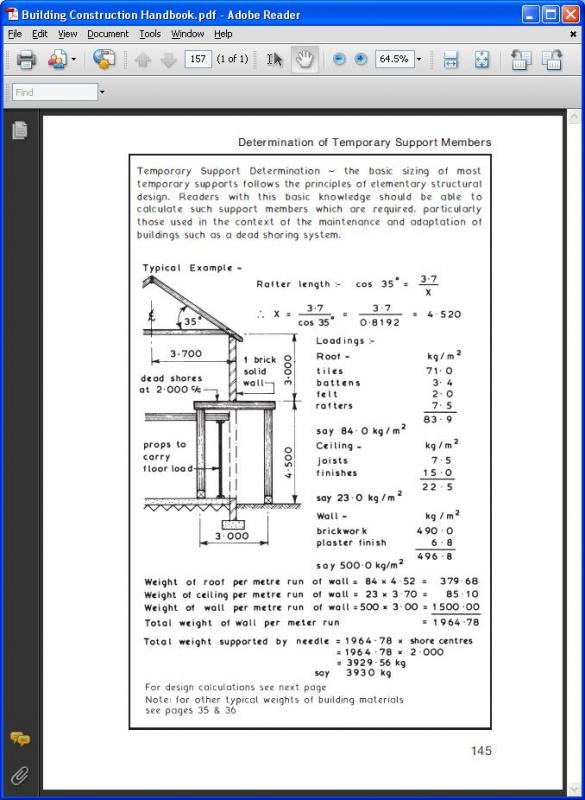

My problem, as I see it, is to support the brickwork above, whilst installing the steel. This is normaly a straightforward job with acros. But how do I support the brickwork when there is nowhere for the acros to be positioned outside the window? Would supporting the joists internally be sufficient for the few hours it'd take to fit the steel and make good above or is there another solution. I've even considered building supports jutting out from the outside wall below floor level!!!!!

Thanks guys!

BUT I am now about to embark on the kitchen which involves taking out a wall where a window is currently sited. The window is on the first floor of a 3 storey building (G, 1 & 2) and is around 1.8m wide (the window, not the building lol). I need to fit a 3m bio-fold door in it's place which will open onto a large balcony, yet to be built.

The intention is to make the reveal, then fabricate the bottom and fit a cheap softwood window until such time as the kitchen is completed. Then, when the balcony has been erected, remove the window and fabrication, and install the bio-fold door.

My problem, as I see it, is to support the brickwork above, whilst installing the steel. This is normaly a straightforward job with acros. But how do I support the brickwork when there is nowhere for the acros to be positioned outside the window? Would supporting the joists internally be sufficient for the few hours it'd take to fit the steel and make good above or is there another solution. I've even considered building supports jutting out from the outside wall below floor level!!!!!

Thanks guys!