Ive put this in electrics as it is specifically an electrical question.

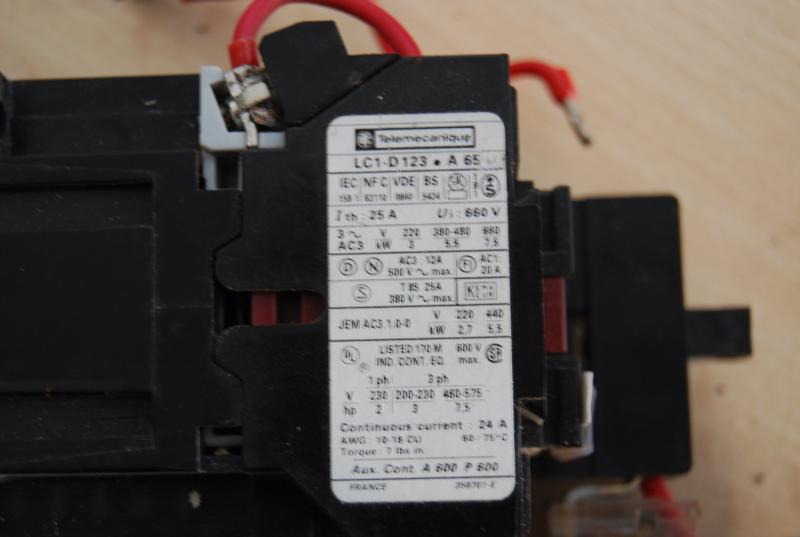

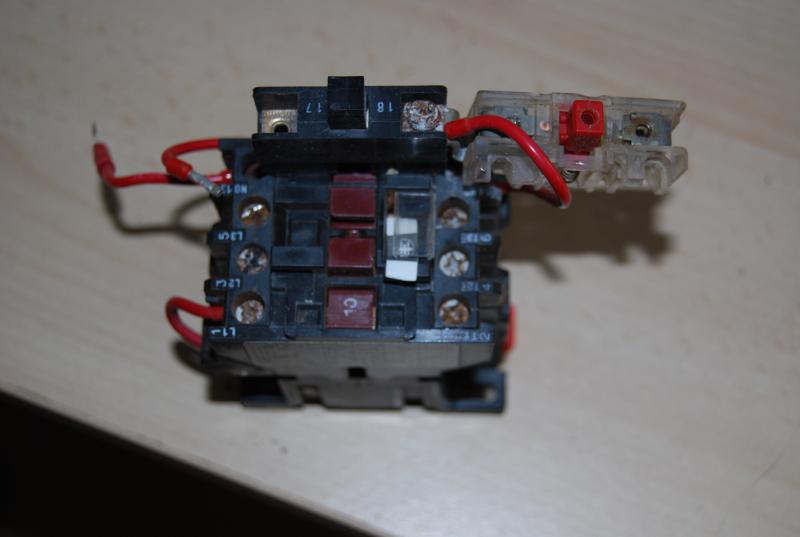

i have a large old dewalt planer thicknesser type dw1150, which is a 240volt model. The incoming wiring goes through an industrial type on off switch box, with a large red stop button. from there it goes to a small box that has a condensor in it. When i bought it the old boy said it needed a new condensor.

When i opened it up to replace the condensor (which ive done) i found there were some wires that were unconnected in the switch gear housing. Having managed to get some photos from someone else with a working one, ive wired it all up as it should be. When i power it up i get a hum from but nothing else. (also stops humming if i press the off switch!) the motor turns freely by hand.

Based on the limited info ive posted so far anyone got any ideas?

secondly, what is the function of a condensor?

Ill see what other info i can get from the machine if needed.

i have a large old dewalt planer thicknesser type dw1150, which is a 240volt model. The incoming wiring goes through an industrial type on off switch box, with a large red stop button. from there it goes to a small box that has a condensor in it. When i bought it the old boy said it needed a new condensor.

When i opened it up to replace the condensor (which ive done) i found there were some wires that were unconnected in the switch gear housing. Having managed to get some photos from someone else with a working one, ive wired it all up as it should be. When i power it up i get a hum from but nothing else. (also stops humming if i press the off switch!) the motor turns freely by hand.

Based on the limited info ive posted so far anyone got any ideas?

secondly, what is the function of a condensor?

Ill see what other info i can get from the machine if needed.