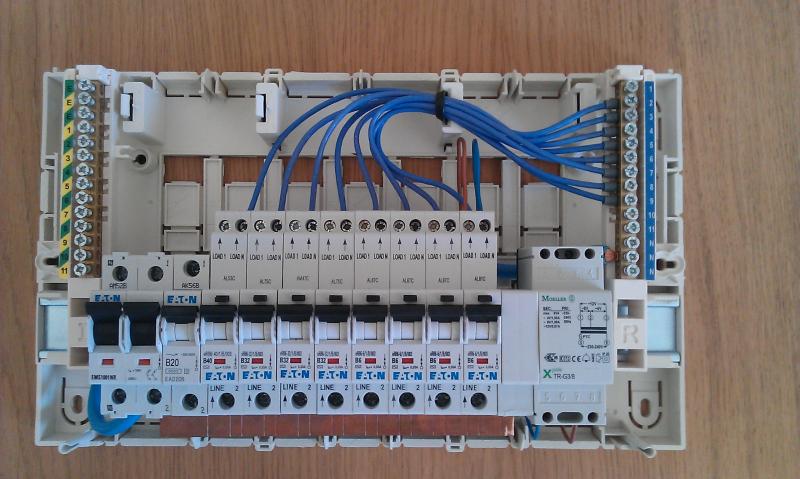

I want to cut, and put bootlace ferrules on, 8 RCBO neutrals. They're way too long at the moment. See below.

I can find ferrules for a sensible price, but anything to crimp them seems to be £100+. Shortening these cables is worth a few quid to me, but I only need to crimp 8 ferrules, so I can't justify spending that kind of money. Are the £100+ crimps the only way to crimp bootlace ferrules? This price looks promising http://tinyurl.com/c7y6uvo

http://tinyurl.com/c7y6uvo

Also, if I can find a suitable way of crimping, what size ferrules would I be after? They seem to be specified in thickness and diameter, right?

http://www.cablecrimper.co.uk/product-info.php?ccs-pid243.html

Cheers

I can find ferrules for a sensible price, but anything to crimp them seems to be £100+. Shortening these cables is worth a few quid to me, but I only need to crimp 8 ferrules, so I can't justify spending that kind of money. Are the £100+ crimps the only way to crimp bootlace ferrules? This price looks promising

Also, if I can find a suitable way of crimping, what size ferrules would I be after? They seem to be specified in thickness and diameter, right?

http://www.cablecrimper.co.uk/product-info.php?ccs-pid243.html

Cheers