- Joined

- 17 Apr 2007

- Messages

- 2,666

- Reaction score

- 141

- Country

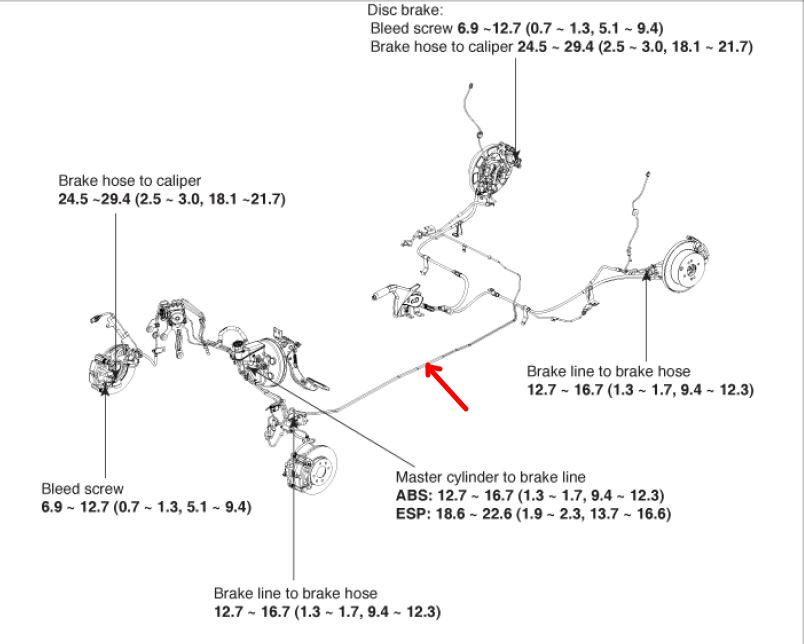

2009 i20 1.4 PB has a weeping spot on one of the long runs to the back so on the drive till fixed.

Anyone know what size/standard of pipe and fittings Hyundai use?

Are the in situ jointing tools worth considering?

Anyone know what size/standard of pipe and fittings Hyundai use?

Are the in situ jointing tools worth considering?

Last edited: