You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air lock i think

- Thread starter scotthud

- Start date

i didnt see the water rise or notice any bubbles so id say no but cant be 100%While you were blocking the vent pipe did any water come into the tank thro what is normally the outlet pipe to the system?

It is a drain valve over the boiler, but there could be any number of them fitted in the system, particularly where there's a separate leg where draining off near the back door wouldn't empty that part of the pipework

Great now i understand what im 'trying' to acheive, tonight after work ill manually take some water out of the F&E tank as its full, and block off the feed pipe (A in the drawing right?) and then ill stick a hose on one of the downstairs radiators and see if it forces water up through the outlet (B in the drawing if im understanding this right) any suggestions best way to block off feeder pipe (A) or should i just use my hand/fingers? also how long should i try and force water through for? and I really appreciate all your help and suggestions.

Last edited:

Your understanding is correct.

If the tank is still full and the ballcock is still held up and the radiators are still empty then you certainly have a blocked feed pipe (B)

I would use a plastic stop end to block the vent pipe (A)

On its own the blocked pipe isn’t stopping your heating working.

Regarding how long should you try ... it’s the pressure you need rather than the time ... a short burst of high pressure might dislodge the blockage instantly.

Not being familiar with you radiator valves I’m assuming you have to remove or unscrew a plug inside the drain off spout while the main valve is open in order to get the mains pressure from the from the hose to enter.

If I had the same problem I would fill the system up slowly using the hose as you are doing - but would go round the radiators in turn and bleed them till they are all completely full downstairs - and then the same upstairs - and then any other bleed points that have been fitted in the loft.

I’m making an assumption that when the system was completely full it would start coming out of the vent pipe (A) and fill the F&E tank and overflow outside – (Someone will confirm if this is correct)

At this point you could turn the hose pipe off, block the vent pipe (A) and give the feed pipe (B) a quick blast of mains pressure from the hose and into the tank if it dislodged the blockage.

Or, you could turn the radiator valve off next to the hose quickly remove the hose replace the drain plug and try the heating.

If the tank is still full and the ballcock is still held up and the radiators are still empty then you certainly have a blocked feed pipe (B)

I would use a plastic stop end to block the vent pipe (A)

On its own the blocked pipe isn’t stopping your heating working.

Regarding how long should you try ... it’s the pressure you need rather than the time ... a short burst of high pressure might dislodge the blockage instantly.

Not being familiar with you radiator valves I’m assuming you have to remove or unscrew a plug inside the drain off spout while the main valve is open in order to get the mains pressure from the from the hose to enter.

If I had the same problem I would fill the system up slowly using the hose as you are doing - but would go round the radiators in turn and bleed them till they are all completely full downstairs - and then the same upstairs - and then any other bleed points that have been fitted in the loft.

I’m making an assumption that when the system was completely full it would start coming out of the vent pipe (A) and fill the F&E tank and overflow outside – (Someone will confirm if this is correct)

At this point you could turn the hose pipe off, block the vent pipe (A) and give the feed pipe (B) a quick blast of mains pressure from the hose and into the tank if it dislodged the blockage.

Or, you could turn the radiator valve off next to the hose quickly remove the hose replace the drain plug and try the heating.

Not being familiar with you radiator valves I’m assuming you have to remove or unscrew a plug inside the drain off spout while the main valve is open in order to get the mains pressure from the from the hose to enter.

If you look at the picture in post #6 where the water is coming out that is what i have been draining and backfilling from -connecting the outside hose to.

If you look at the picture in post #6 where the water is coming out that is what i have been draining and backfilling from -connecting the outside hose to.

It’s a combined radiator valve and drain off presumably - you use the white knob to turn the radiator on and off - how do you control the drain off - is there a plug inside the tube you remove with a bleed key ?

Yes i just use the bleed key to open close that drain valve, every radiator in the house has this on them, i have three radiators where i cant open these valves for various reason (to close to wall, one is rounded plug valve and the other the pipe is dented so the bleed key wont fit in) but i assume i can drain / fill from anyone

In the pictures in #13 can you tell me (if you can) if the 4 pipes going to/from the air separtor are 22mm ? and one of them that connect to the bottom of the pump can that be unscrewed from the pump instead of cutting? im just looking at the worst case that air separator needs cutting out and cleaning and the pipes to /from it unblocking

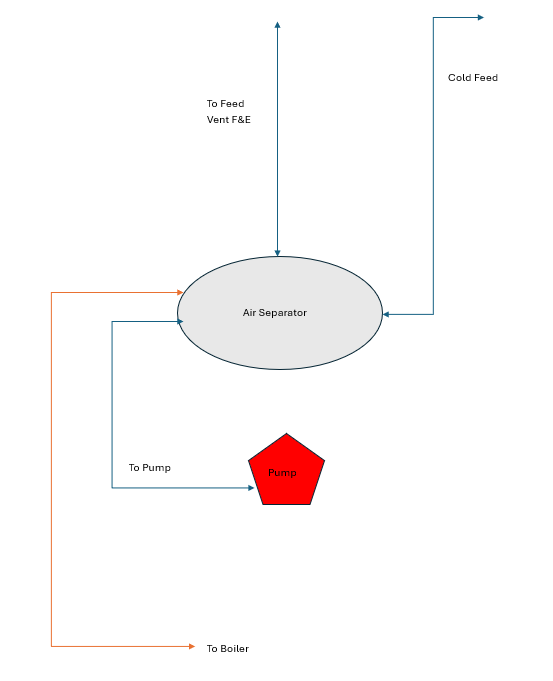

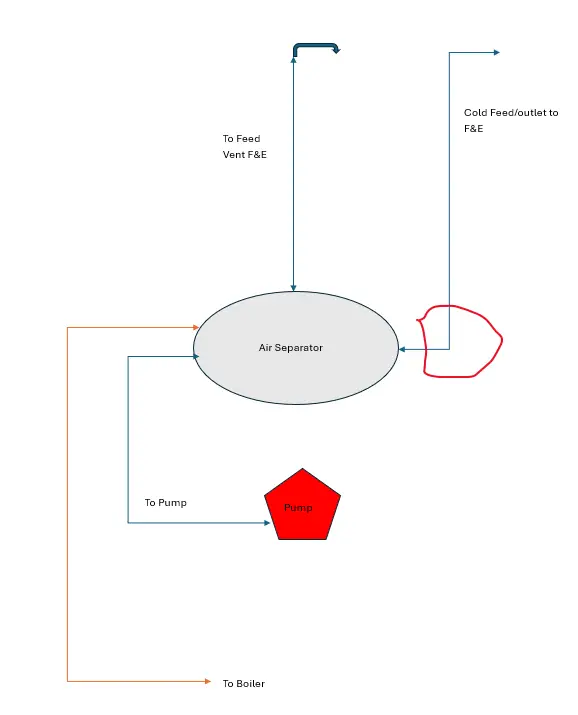

Does this diagram look right looking at those picture in #13

Does this diagram look right looking at those picture in #13

Last edited:

Didnt get chance last night to try the block feed off and backfill, but had a thought about if i needed to cut the air separator out.

Would another option be to cut the 4 pipes ( think they are 22mm) and clean out the Air Separator/Pipe work then re attach it using compression connectos, although a tight space to work in?

This pic is me leaning over the cylinder

Would another option be to cut the 4 pipes ( think they are 22mm) and clean out the Air Separator/Pipe work then re attach it using compression connectos, although a tight space to work in?

This pic is me leaning over the cylinder

Didnt get chance last night to try the block feed off and backfill, but had a thought about if i needed to cut the air separator out.

Why no just cut out the cold feed where it enters the separator first, you should/might be able to clean out the separator, if the cold feed is blocked further back then just cut it further up to clear it, you then only require two compression fittings.Would another option be to cut the 4 pipes ( think they are 22mm) and clean out the Air Separator/Pipe work then re attach it using compression connectos, although a tight space to work in?

This pic is me leaning over the cylinderView attachment 339831

Thanks when i tested with a magent it only seemed to stick / get attracted to the pipes very close the separator? so if i cut close to the separator then how do i clear it out as wouldnt i just dislodge anything and 'move it further around system, or if that is the purpose should i then had some sentinal x400 or something to 'clean' system

Looking at my pipe work and tracking the pipes down from loft it appears to be like this, does this look correct and the red circle is that where you on about cutting it? and a very stupid question what 'gap' should there be between the pipes for a compression connector to fit.

Looking at my pipe work and tracking the pipes down from loft it appears to be like this, does this look correct and the red circle is that where you on about cutting it? and a very stupid question what 'gap' should there be between the pipes for a compression connector to fit.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 1

- Views

- 5K