Hello all,

I'm looking for a bit of advise please. I'll explain the problem, show you how I think I might be able to fix it and you can all tell me how wrong I am and tell me how it should be done.

Problem:

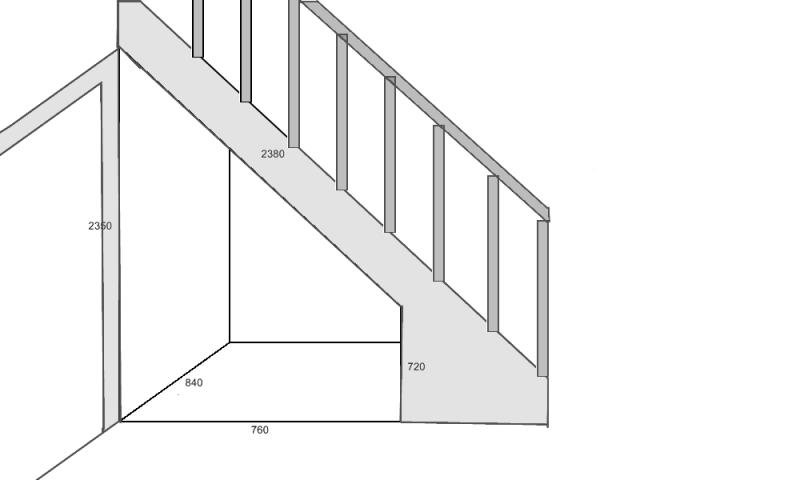

I'm hoping to block in under my stairs, to create a large cupboard, I need a reasonable size door since I need to store big things in there (like musical instruments). See pic for shell with dimensions (even a rubbish picture speaks a thousand words):

The issues: Although this needs to be a solid structure I want to damage the laminate flooring as little as possible. The house is in a shared ownership scheme (with a housing association) so I have to be careful about things like that.

My Idea:

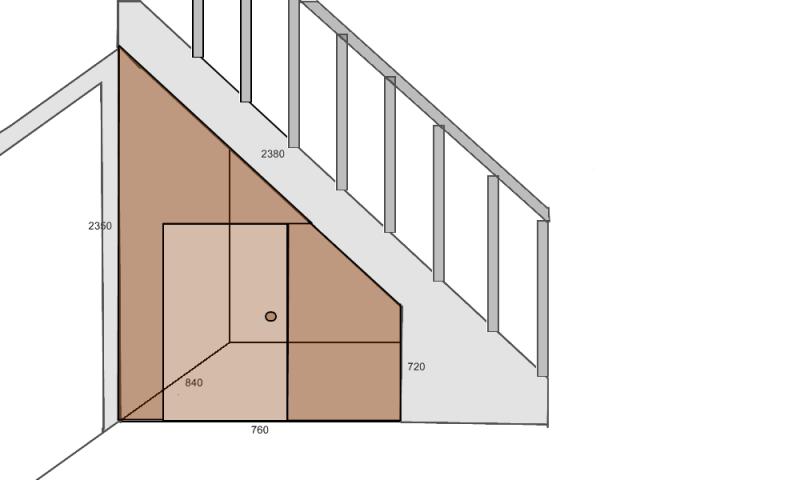

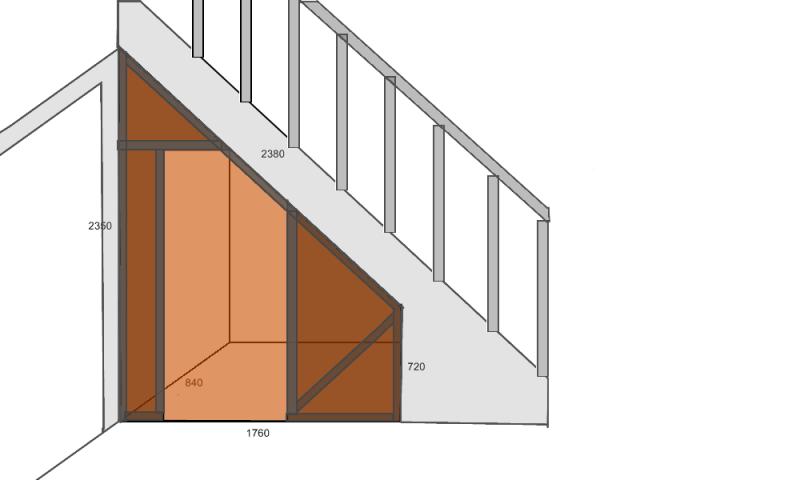

So my idea is to use two pieces of 2440x1220x18 MDF board and basically panel it all in. Cutting a door out and putting it on hinges with a small subtle handle, I would then finish with a white gloss paint to match the stair case...again, see bad picture(colours for clarity only):

My Questions:

Is this a good idea? (is there an obvious alternative)

I'm good at DIY and woodwork but have never done anything that actually requires "Structural" type work. Since this is almost a temporary wall type project (but don't want to go down the stud wall route)

If this is a reasonable plan, what is the best way to secure the wall/cupboard? Is there a clever way to do it which would allow the least amount of flooring fixtures?

Please share your ideas and ask if I need to clarify further

I'm looking for a bit of advise please. I'll explain the problem, show you how I think I might be able to fix it and you can all tell me how wrong I am and tell me how it should be done.

Problem:

I'm hoping to block in under my stairs, to create a large cupboard, I need a reasonable size door since I need to store big things in there (like musical instruments). See pic for shell with dimensions (even a rubbish picture speaks a thousand words):

The issues: Although this needs to be a solid structure I want to damage the laminate flooring as little as possible. The house is in a shared ownership scheme (with a housing association) so I have to be careful about things like that.

My Idea:

So my idea is to use two pieces of 2440x1220x18 MDF board and basically panel it all in. Cutting a door out and putting it on hinges with a small subtle handle, I would then finish with a white gloss paint to match the stair case...again, see bad picture(colours for clarity only):

My Questions:

Is this a good idea? (is there an obvious alternative)

I'm good at DIY and woodwork but have never done anything that actually requires "Structural" type work. Since this is almost a temporary wall type project (but don't want to go down the stud wall route)

If this is a reasonable plan, what is the best way to secure the wall/cupboard? Is there a clever way to do it which would allow the least amount of flooring fixtures?

Please share your ideas and ask if I need to clarify further