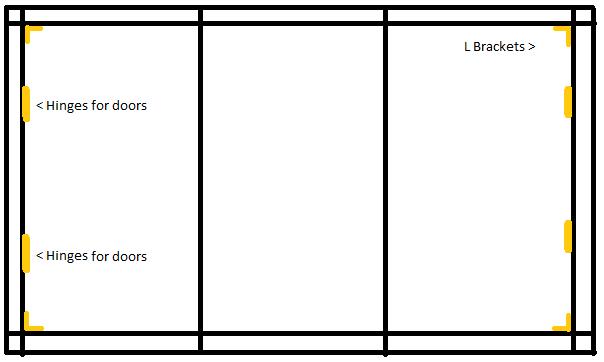

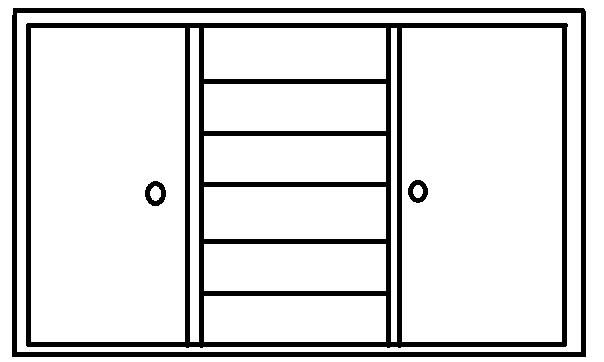

I am attempting to build a set of built in cupboards in one of our bedrooms. This really is my very first attempt at something like this but I know I have a common sense for things like angles and weak spots etc. I would just like a bit of guidance and suggestions if anyone has any. So to begin, ideally I would like two cupboards either side flanking a book shelf (which I have detailed in one of my diagrams). I would like to buy reclaimed pine doors, and to keep the timber on display old looking as our house is a character house from the 1800s. I would build the subframe out of standard studwork timber, however what would be the best size to use? I have seen that 38x38mm is best, but will that be appropriate with the relatively heavy doors? I would also like to hear any recommendations on how I should do the joins where the studwork crosses. I have also attached a diagram of roughly how I'd like to do the subframe - obviously it's not 3d but it's an idea. Lastly for now I'd like to ask how to fix the timber to the ceiling as it's an old lathe and plaster one. Would I need to find a joist above to fix to?

That's not loads of detail, but enough to start!

That's not loads of detail, but enough to start!