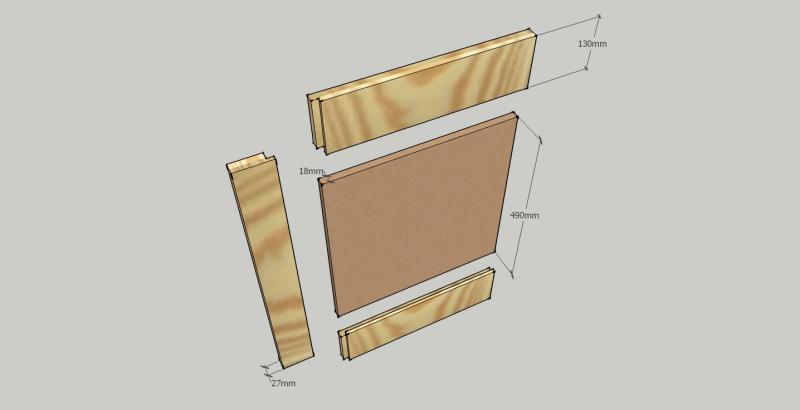

Quick q ... bit confused by construction technique for a cabinet door. Want to use 27mm thick Pine rails & stiles ... with 18mm MDF panel inset ... but I don't want to go to the hassle of making a groove etc., just want it to sit in a rebate.

Is that ok? Or will gluing/nailing the panel to the pine outside 'frame' defeat the whole purpose of a panel door?

This is for a living room type area - not high moisture etc.

Picture attached!

Is that ok? Or will gluing/nailing the panel to the pine outside 'frame' defeat the whole purpose of a panel door?

This is for a living room type area - not high moisture etc.

Picture attached!