Thanks Harry, we are not really trying to drive down the overall amount of gas used we just need to have the whole house at a nice warm even temperature as efficiently as possible. Yes alll the rads have TRV's but I am yet to be convinced they improve efficiency of the system other than when you turn them off. Ours do not seem to maintain a constant comfortable temp. in individual rooms so I just wind them all to fully open & have the room stat in the room which seems to cool the quickest. In our case that is the kitchen because it has 3 exterior walls.To add to what the others have said....

A combi boiler has to be sufficiently large in Kw, to cope with serving the HW, so that limits how low they can modulate, to avoid the inefficient on/off switching. The result is that in most cases the heat output will be too much for most homes when called to serve the CH.

In your case, I would suggest that if you don't have them already, you fit TRV's to all but the radiator where the room thermostat is. It might even be worth fitting those programmable TRV's which Eric seems to be familiar with, because they can switch heating in rooms on and off individually on a timed basis.

My own way of dealing with the energy cost at the moment, is to have the CH set to just provide a general background temperature of 16C, during the day and make use of a radiant gas fire in the living room. I also use an electric blanket, to preheat my bed, switched on via Alexa and a Smart Plug. I take the wireless stat into the living room with me, so when I light the gas fire - the thermostat sees the heat from the fire, and it fools it to turn the CH off.

My regime has made quite a difference to my overall gas consumption.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Central Heating economy of running 24 hours

- Thread starter jj4091

- Start date

18c??? my lounge is 19.1c in morning when no heating is on during the cold snap, this is cold and we can all feel it. I dont know how people can set it to 17c to 18c and still say the house is warm.I've been doing a test since November, I'm running my boiler 24/7.

In November I used 30% less gas.

I set the heating flow temp of 45° and hot water temperature of 62°.

Powering 10 rads and UFH (single room)

My usage is less than last years, but I have set the temps lower too, they are at 18°

House is permanently warm, (the rads feel barely warm) in a nice way, doubt I'll set the thermostat higher, there's no need.

House is old, but insulated, and boiler is 4 year old Combi.

- Joined

- 27 Jan 2008

- Messages

- 27,812

- Reaction score

- 3,369

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

I use to heat things much hotter, I trained in heat treatment, and it was clearly not linear, by how much at such low temperatures it is hard to tell however.I thought it was linear?

How EvoHome works varies, it can work with OpenTherm, the same must be said for the boilers, as the user we are unaware of the algorithms built into any boiler, because one boiler when switched off, restarts at flat out, does not mean all boilers do. However some clearly after being switches off with an external on/off device turn back on at full output, and many boilers don't gain the latent heat while at maximum output, the whole design of most boilers is to be controlled by a modulating device, be it to the ebus, or on the water flow.Evohome works by firing the boiler on/off multiply times/hour and I never see any complaints re frequent cycling from a ecomomy point of view.

I found setting the TRV's in sequence can speed up re-heat, but it depends on timing, with my oil boiler if the on time is staggered on each radiator by 10 minutes I can get kitchen first, then dinning room, then living room, then hall, and a bigger gap before bedrooms, office and craft room is heated. And the hall has started to heat before the boiler starts to cycle, but increase the times to 15 minutes, and the boiler starts to cycle before hall starts to heat.

My pump is on the return, and I have no by-pass valve, it would not work with pump on the return, and I have found with micro bore piping there is no real need to trim the lock shield valves, the heat is reasonably shared between radiators, and closing the lock shield means more water thermo-syphons through the domestic hot water so boiler turns off early.

However this was not the case with mothers old house with a gas modulating combi boiler, once set radiators never got stinking hot, the boiler modulated to maintain the water flow at a temperature which maintained all the rooms at the temperatures set on the TRV's, the only problem I had was the anti hysteresis software on the TRV's was OTT, so set the room from 16°C overnight (it rarely cooled that much) to 20°C in the morning at 7 am, it was 11 am before it reached 20°C, so I would set to 22°C and then at 8 am down to 20°C and the room was at 20°C by 8 am. However this means geofencing would not really work with the TRV heads I was using.

I note the Drayton Wiser TRV head is claimed to have algorithms to work out how long it takes to heat the room, so with those TRV heads goefencing would likely work.

Without electronic heads the rooms can only be set to maximum temperature, on leaving mothers house the electronic heads were removed and the mechanical put back, however by this time the lock shields had been trimmed using the temperatures reported on the PC,

with current and target reported it is easy to turn down the lock shield a tad if the current exceeds target, which with 15 mm pipe work it did to begin with, once set the rooms were spot on, except when the sun through bay windows caused the temperature to raise, and when the mechanical TRV's were put back on, the rooms continued to be spot on with temperature. Though of course took longer to heat up, as heating all rooms together.

with current and target reported it is easy to turn down the lock shield a tad if the current exceeds target, which with 15 mm pipe work it did to begin with, once set the rooms were spot on, except when the sun through bay windows caused the temperature to raise, and when the mechanical TRV's were put back on, the rooms continued to be spot on with temperature. Though of course took longer to heat up, as heating all rooms together.I added a further 5 electronic TRV's in this house, cheap enough at £15 each in 2019, I do change batteries annually although they will last two years, but then I forget, with a discharged battery they are designed to open.

I keep pointing out in last 10 years I have lived in three homes, and each one was different, so to say the answer is electronic TRV's may work with one home, but be useless with another, the did work far better with the gas modulating boiler to with this on/off oil boiler. But also moved from 15 mm pipe work and by-pass valves, to micro bore and thermo syphon. And with three floors, and 14 rooms, turning off rooms not being used is far more important than with mothers house with only 6 rooms, where the kitchen had to double as a laundry room. Here the laundry room is not heated except by the washing machine, dryer, and press.

The only thing I am now confused by is the relevance of boiler modulation to the cycling on & off of the room stat. surely it just gets to the set temp then stops supplying the boiler power & reconnects a supply to the boiler once it has dropped below that set temp.. Our stat seems to open & close in half a degree increments.

A boiler, where the control system is only able to indicate heat needed or not, can only modulate it's output based on the flow temperature out of the boiler.

A boiler, where a more advanced control system is installed, which advises the boiler how close it is to the set temperature, is much better. The boiler can begin modulating it's output much earlier and can modulate it output at start up, to match the demand for heat. The better the boiler modulation is matched to the demand, the more efficient it is.

Yes alll the rads have TRV's but I am yet to be convinced they improve efficiency of the system other than when you turn them off. Ours do not seem to maintain a constant comfortable temp.

TRV's do not set the room temperature, rather they limit the maximum temperature the room can achieve. Which is the reason why your stat needs to be in the room without a TRV and needing the more regular heat input.

Obviously, once a room hits the TRV's set temperature, it will then start to ramp down the flow, which will reduce the need for heat input from the boiler, so less gas consumed/ more economical. I have the TRV's in less used rooms set at 1, the lower they are set, the more they save.

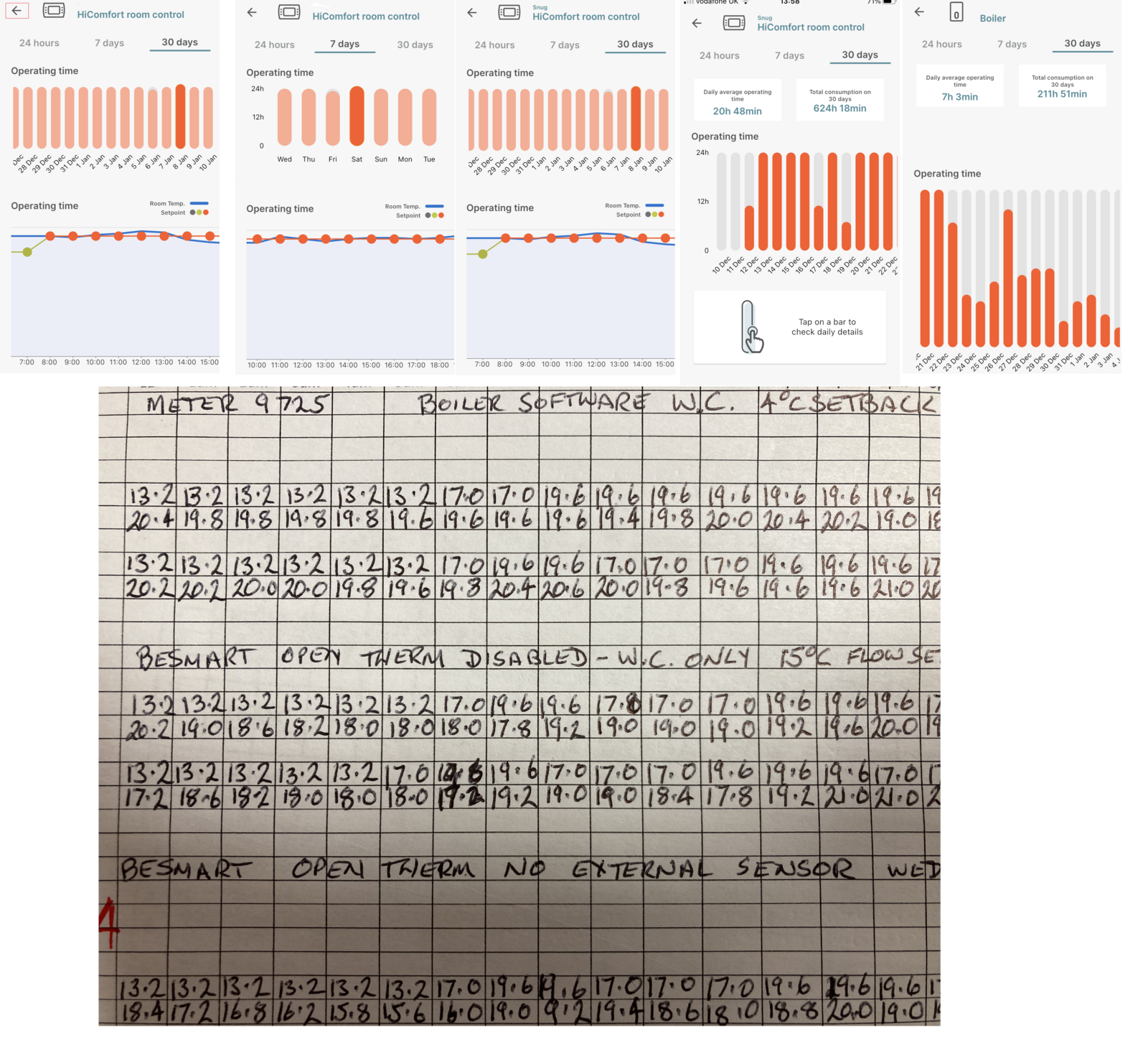

This is a rehashed post from a gas group I belong to, I did this from the 7th Jan to yesterday. might be of some interest. Using the new pre-production server and wi-fi gateway but the old BeSmart room control.

Control system comparisons

There are often posts from customers and installers showing a snapshot of the performance of their new boiler and or controls system and sometimes a comparison of the fuel consumption of the previous system to that of the consumption of the new boiler or controls combination.

These are all well and good but they’re either a moment in time showing textbook settings to praise or criticize a new or favourite boiler, heat pump and control but omit other details so it’s of value but certainly not definitive. In all fairness is they’re not claimed to be, just customers or installers showing the results or favourites.

Here is another non-definitive showcase but it’s a comparison of control regimes in the one property with the same occupants the same boiler and across several days of similar weather but with different control regimes to illustrate, or try to, the performance of different control systems.

Once installed a heating system has two main items of importance, comfort and cost so I recorded each

Each configuration ran firstly for two days then the following week the same configurations for 24 hours as a sort of double check to see if there were anomalies.

The actual amount of natural gas consumed is unimportant as that would change from property type to property type but the percentage increase of one configuration to another from the lowest is the best comparison.

Also comfort levels; each hour the target and actual temperatures were compared and recorded.

Configuration 1: Weather compensation using internal boiler software only operating at two temperatures, a comfort and setback, the setback being 4°C lower than the comfort level.

Configuration 2: Weather compensation using an OpenTherm control with no internal reference so the OpenTherm WC software was the WC control, not the boiler. The setback was not a room temperature target but defined by the reduction in the boiler flow temperature of 20°C (I had tried a lower reduction in the first two day trial of 15°C with little effect).

Configuration 3: OpenTherm control using internal reference plus external sensor with three temperature levels.

Configuration 4: OpenTherm control, three temperature levels but external sensor disconnected.

Configuration 5: OpenTherm disabled and disconnected, the control operating as an ON/OFF control across the same three temperature levels.

I had to cancel option 5 as the ON/OFF relay in the prototype control wi-fi box was sticking and it was 24°C in the bedroom at 2am each time.

For comfort weather compensation was the most consistent unsurprisingly but also the most fuel intensive.

Most consistent was WC from boiler software but also most expensive

WC but from OpenTherm Software, less fuel intensive but very consistent

OpenTherm with WC combined, less consistent due to temperature changes and reduced fuel use.

More cost effective was OpenTherm alone by a margin but weather did ease slightly over the two days and consistency less than WC due to three temp change levels.

Frankly my choice, unless I care to do this again to confirm, would be OpenTherm with external sensor but limited to two temperature levels setback 4-5°C below comfort. The reasons for this are twofold, slight overheating of our sitting room with WC in the evening when doors closed watching TV, room control would negate this, something an external sensor and boiler software located elsewhere would find problematic and I would want to limit inconsistency caused by temperature changes to just two and not three.

Control system comparisons

There are often posts from customers and installers showing a snapshot of the performance of their new boiler and or controls system and sometimes a comparison of the fuel consumption of the previous system to that of the consumption of the new boiler or controls combination.

These are all well and good but they’re either a moment in time showing textbook settings to praise or criticize a new or favourite boiler, heat pump and control but omit other details so it’s of value but certainly not definitive. In all fairness is they’re not claimed to be, just customers or installers showing the results or favourites.

Here is another non-definitive showcase but it’s a comparison of control regimes in the one property with the same occupants the same boiler and across several days of similar weather but with different control regimes to illustrate, or try to, the performance of different control systems.

Once installed a heating system has two main items of importance, comfort and cost so I recorded each

Each configuration ran firstly for two days then the following week the same configurations for 24 hours as a sort of double check to see if there were anomalies.

The actual amount of natural gas consumed is unimportant as that would change from property type to property type but the percentage increase of one configuration to another from the lowest is the best comparison.

Also comfort levels; each hour the target and actual temperatures were compared and recorded.

Configuration 1: Weather compensation using internal boiler software only operating at two temperatures, a comfort and setback, the setback being 4°C lower than the comfort level.

Configuration 2: Weather compensation using an OpenTherm control with no internal reference so the OpenTherm WC software was the WC control, not the boiler. The setback was not a room temperature target but defined by the reduction in the boiler flow temperature of 20°C (I had tried a lower reduction in the first two day trial of 15°C with little effect).

Configuration 3: OpenTherm control using internal reference plus external sensor with three temperature levels.

Configuration 4: OpenTherm control, three temperature levels but external sensor disconnected.

Configuration 5: OpenTherm disabled and disconnected, the control operating as an ON/OFF control across the same three temperature levels.

I had to cancel option 5 as the ON/OFF relay in the prototype control wi-fi box was sticking and it was 24°C in the bedroom at 2am each time.

For comfort weather compensation was the most consistent unsurprisingly but also the most fuel intensive.

Most consistent was WC from boiler software but also most expensive

WC but from OpenTherm Software, less fuel intensive but very consistent

OpenTherm with WC combined, less consistent due to temperature changes and reduced fuel use.

More cost effective was OpenTherm alone by a margin but weather did ease slightly over the two days and consistency less than WC due to three temp change levels.

Frankly my choice, unless I care to do this again to confirm, would be OpenTherm with external sensor but limited to two temperature levels setback 4-5°C below comfort. The reasons for this are twofold, slight overheating of our sitting room with WC in the evening when doors closed watching TV, room control would negate this, something an external sensor and boiler software located elsewhere would find problematic and I would want to limit inconsistency caused by temperature changes to just two and not three.

A boiler, where the control system is only able to indicate heat needed or not, can only modulate it's output based on the flow temperature out of the boiler.

A boiler, where a more advanced control system is installed, which advises the boiler how close it is to the set temperature, is much better. The boiler can begin modulating it's output much earlier and can modulate it output at start up, to match the demand for heat. The better the boiler modulation is matched to the demand, the more efficient it is.

Not entirely the case and it rather depends on the boiler but high spec entry level boilers will modulate on both flow and return and start -up from a graduated range rated output (not maximum heating output) and increase output dependent on duration of demand.

- Joined

- 11 Apr 2022

- Messages

- 992

- Reaction score

- 216

- Country

Have you thought about getting smart TRV’s to control the heat in individual rooms? The Drayton Wiser, Hive and Tado control systems will allow a room by room level of control.Thanks Harry, we are not really trying to drive down the overall amount of gas used we just need to have the whole house at a nice warm even temperature as efficiently as possible. Yes alll the rads have TRV's but I am yet to be convinced they improve efficiency of the system other than when you turn them off. Ours do not seem to maintain a constant comfortable temp. in individual rooms so I just wind them all to fully open & have the room stat in the room which seems to cool the quickest. In our case that is the kitchen because it has 3 exterior walls.

I have used mechanical TRVs for years with a oil fired boiler and they certainly do control the set temperature within quite reasonable limits as long as the boiler is firng "continuously", I can see where they may not work well with gas boilers that can't modulate (down) to the heat demand. A oil fired boiler cycles all the time but the flow temperature will allways be within the boiler stat hysteresis of say 10C, gas boilers on the other hand have a anticycle time which has to be long enough to get the flow temp low enough so as that it doesn't exceed its SP by more than 5C on firing up as all gas boilers to my knowledge fire up at ~ 60% output for stable ignition and must the be able to modulate low enough fairly rapidly to avoid reaching SP+5C and again recycling, Vaillants are or were even worse, they maintain ignition conditions for 60 secs bvefore allowing any modulation so the boiler temperature has to be very low to avoid recycling. Oil fired boilers fire up obviously at 100% but the Hx acts as a quite usefull 20/30 litre buffer. Gas boilers generally IMO havn't kept up with improved insulation, and zoning etc where the heat demand can go well below the minimum output of most boilers which is still ~ 5 to 8kw.

I think that's right in practice. Resistance to heat loss from house to outside is in 3 parts in series - air inside to inside of wall (convection), through wall (conduction), and outside of wall to outside air (convection). Conduction through the wall is the biggest, and is linear with ∆T, so if convection is non-linear overall it's practically linear.I thought it was linear?, I'm allways a bit skeptical of this myself, however thats whats used in calculating heat losses.

As you say, rad to room is different, I've always use ∆T^1.25 but it's not an exact science.

As you say, rad to room is different, I've always use ∆T^1.25 but it's not an exact science.

What does the ^ mean?

Is rad to room different because convection is higher when rad temperature is higher?

^ is "to the power of"

Thanks. So would squared be written ^2 ?

Resistance to heat loss from house to outside is in 3 parts in series - air inside to inside of wall (convection), through wall (conduction), and outside of wall to outside air (convection). Conduction through the wall is the biggest, and is linear with ∆T, so if convection is non-linear overall it's practically linear.

I'd just been trying to Google that exact information! Just what I wanted.

Yes, just write 2^2 into google search and you will get 4.Thanks. So would squared be written ^2 ?

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 9

- Views

- 5K

- Replies

- 14

- Views

- 2K

- Replies

- 16

- Views

- 30K