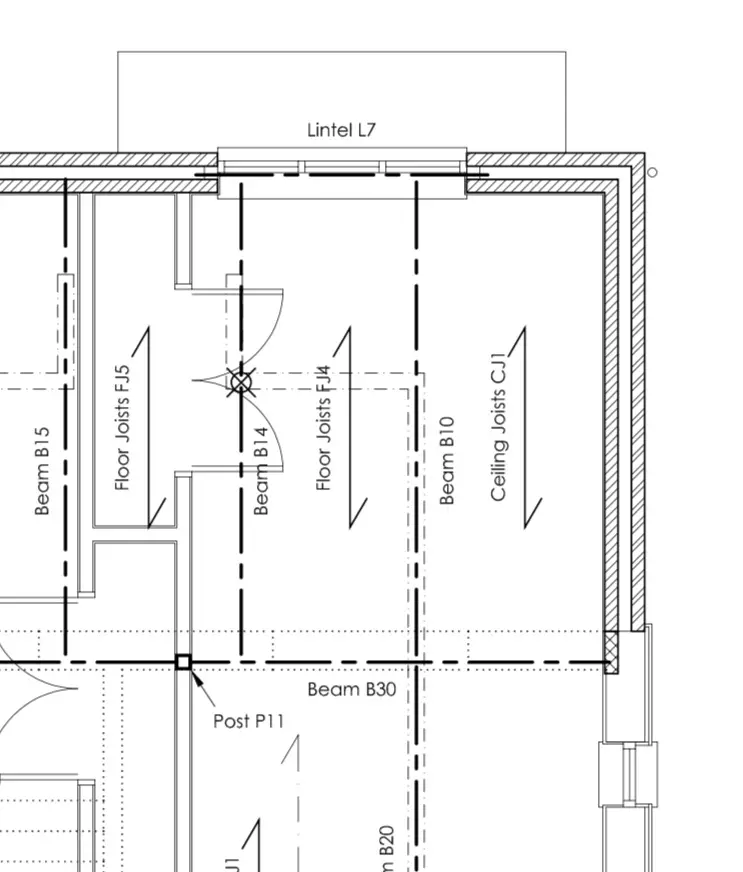

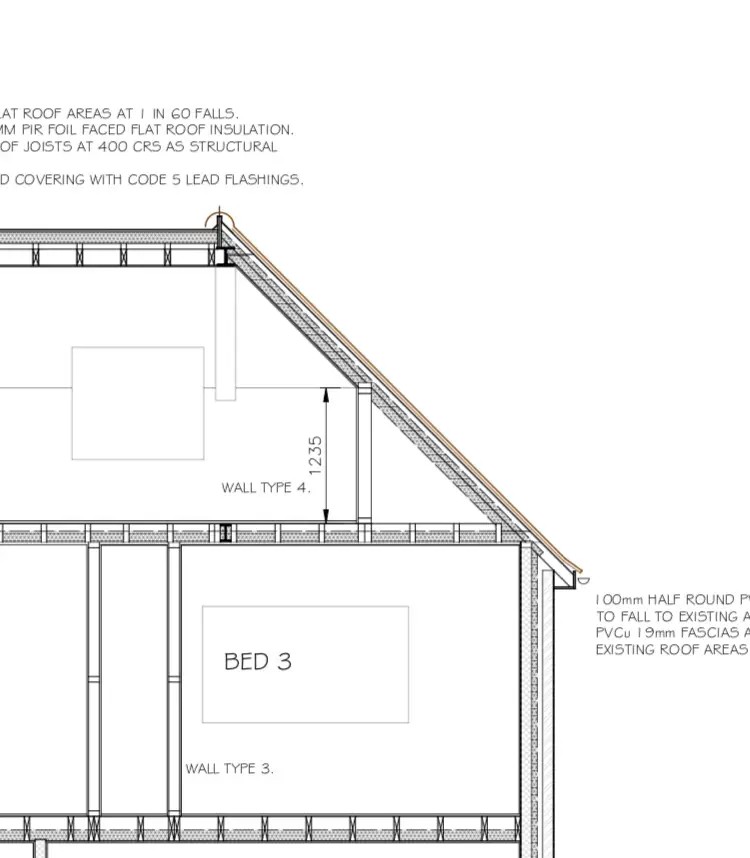

Re: design. These are the plans. This is B14 in the plan , under the ‘ridge’ in the section. It is hipped roof so no gable.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clipping the end of a steel / Structural Issue

- Thread starter RichA

- Start date

@ OP; look at the 'Unfactored reactions (Kn) total' near the top-right of the sheet. There are two figures in bold - 7.94Kn and 11.46Kn. These are the loads which each end of the beam puts on its supporting structure. The worst case is obviously 11.46; assume this is the load supported on your wallplate, then it is only one-half of the load which the timber can safely sustain without crushing (see figures in a previous post).

There is no need to cut it and fix a padstone.

There is no need to cut it and fix a padstone.

Well that photo makes me very nervous and I would have been straight on the phone to the engineer. I can understand why they needed to chamfer the end of the beam to get it in the roof slope but why the vertical cut that goes half way down the web?

Is it a vertical cut, or could it be a chalk mark??Well that photo makes me very nervous and I would have been straight on the phone to the engineer. I can understand why they needed to chamfer the end of the beam to get it in the roof slope but why the vertical cut that goes half way down the web?

That's beamist.I have to say Ive not seen a beam that colour, around here they always seem to be red oxide colour.

Is it a vertical cut, or could it be a chalk mark??Well that photo makes me very nervous and I would have been straight on the phone to the engineer. I can understand why they needed to chamfer the end of the beam to get it in the roof slope but why the vertical cut that goes half way down the web?

It is a vertical cut. Presumably because they cut through the flange from above using a circular saw (centrally).

We have done similar a few times in the past. But to optimise the steel strength and reduce the size of the cut, we mocked up a rafter and even added the thickness of the batten so that the beam would only need removing what was absolutely necessary. It can mean a bulge in the felt though.

It is a vertical cut. Presumably because they cut through the flange from above using a circular saw (centrally).

So what did your structural engineer say?

I haven't asked him yet; I was trying to get a feel for whether this was normal or whether it was an issue that I need to get him involved in.

If these steels aren't suitable (there are a few like this) then we have a very big issue (£££).

If these steels aren't suitable (there are a few like this) then we have a very big issue (£££).

L

Leofric

Nobody is suggesting concrete padstones should be used in timber frame construction !

The beam is at this level to

The end of the steel beam should not protrude into the felt .As others have said there is no bending stress at the point where the beam bears on the wall so the stress is just in shear, the engineer obviously needs to check the cut out is not excessive.

The beam is at this level to

avoid a downstand into the room below

and has a splayed end to sit below the roof . This has been used in some cases to support dummy chimney stacks which are for appearance only ,have no flue and start above first floor ceiling level. The end of the steel beam should not protrude into the felt .As others have said there is no bending stress at the point where the beam bears on the wall so the stress is just in shear, the engineer obviously needs to check the cut out is not excessive.

ps Is the wallplate tantalised ?

Is it just shear? What about torsion? By making that long vertical cut in the web of the beam I would suspect they have drastically altered the characteristics of the beam. It's been a bloody long time since I did structures at college and I didn't understand it then. Tony is our structures expert here but I would want whoever did the original structural design for this project to take a look.

Warning; the feint-hearted should turn away now:

If you think the OPs' cut is too large, take a look at this done three years ago - and it worked. The beam is a 203 x 203 UC section, supporting a 225 brick wall over about 4m. The only criterion to bother about was the shear force just inside of the padstone. By convention, all the shear force is assumed taken by the vertical web (the flange does not contribute to this) yet there is still sufficient meat left of the web to sustain the force. It goes to show that things not done by the book can still work.

If you think the OPs' cut is too large, take a look at this done three years ago - and it worked. The beam is a 203 x 203 UC section, supporting a 225 brick wall over about 4m. The only criterion to bother about was the shear force just inside of the padstone. By convention, all the shear force is assumed taken by the vertical web (the flange does not contribute to this) yet there is still sufficient meat left of the web to sustain the force. It goes to show that things not done by the book can still work.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 11

- Views

- 12K