Sorry, but do not agree with Static regards maintenance. Have read CBA report with regard to life expectancy of concrete blocks being 60 years but it is not a proven point. Have also read CBA conflicting report stating that life expectancy of dense concrete block does not deteriorate with time, providing it is protected from aggressive chemical or abrasive situations. As your wall is completely encased on the inside and the outside is protected by an approx 150mm thick natural stone wall, I fail to see how any maintenance is, or will ever be required. There is one proven fact that I have read, the first recorded concrete block house built was on Staten Island USA in1837, and is still standing. That makes er 173 years old.

With regard to pointing of stone wall, stopped of on me way to London about 6 months ago to have a look at a large lump of York stone wall that I built with the old gentleman who taught me my trade back in 1953. There were half dozen odd bits of pointing missing down at ground level. Now that was done 57 years ago.

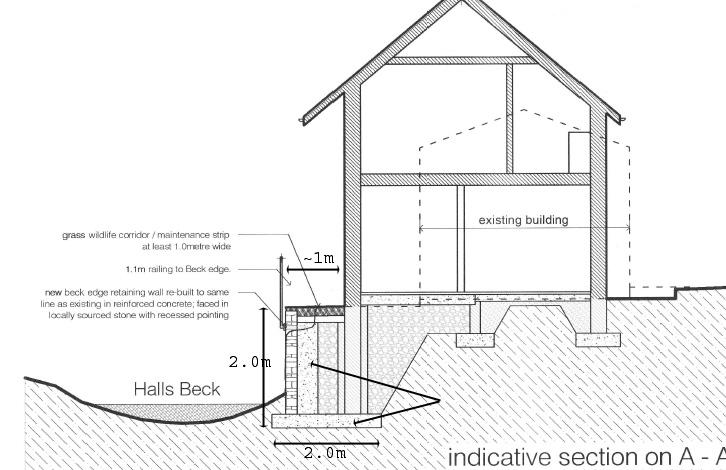

Okay Tul, Get back to post now. As said, sight of a comic is worth a 1000 words, but still very much to the imagination. At least puts me mind to rest about extra meat at bottom of wall. House founds lock all together.

Imagination, such as, what is length of present retaining wall, where does this fit into the equation of the new 33m wall? Why do you want a 33m wall for single unit.? Depth of house as shown about 4.7m. To pitch stairs from river front to first floor back wall and back corridor, with say 4 beds and bathroom, you are looking for about 14m in length. Once again what is rest of wall retaining?

Another point to bear in mind. At the top end of wall, flow end, consider splaying her back into bank at say 20 degrees to stop water going in back of wall when flash flood occurs. Will sweep water out into main channel and down wall.

Will come back to yer excavations and founds later, just want to pop this in.

Don’t know what your local stone is up there, or whether you buy it coursed, cropped, pitched, split ot random, but whatever you get, will have minimum of 150mm thickness, and if she is walled up right, yer can forget er for the next 50 years. The other reason I say block and fill, is that I started to throw a few figures at one another, and it soon came apparent that block and fill was going to come out cheaper and more easy. A good form work chippy would really struggle to rack that lot of shuttering up out of the stream. .

Will come back to excavations later. Consider, throwing your footings to house up to ground level first, and working yer way out to stream. Look at the section on the comic and you may see the reason why. See em. No. Okay, you will only have 450mm working room for house foundations if you work in towards house, no room for scaffold, and if you have a slip whilst blockwork is still green lads will be buried alive. This way they can jump into stream. You say block laid flat, this will only give you 215mm wall, yet you want a 300mm wall from splash course up, so lay 2 flat and one on edge in front to give yer 300mm wall. Bump yer flats up a bit to keep gauge. Reverse bond next course. You will get to ground level in two lifts. Over 900mm high conny blocks swim all over place. you might squeeze 1.050m high,, depending on weather.

Place some concrete blocks in stream as base plates, stand putlogs on them and run 5 board wide scaffold down and over stream. Issue brickies with frogman flippers and snorkels, they can lay back skin of wall overhand, lay front skin and scaffold is in place for stone work.

Am bored now, but there are still a few items to tell yer now that I have seen comic, so if you want will come back in couple days. Flag it up so know you read it.

old un.