Hi All,

I've been studying this and other forums for months off and on and putting all the ideas into a do it all system. I am posting my plans for fitting a heat bank to a combi boiler using a converted 300L unvented cylinder for comments / suggestions and probably ridicule.

First a bit of background.

We are having an extension built which will include 2 additional mixer showers giving a total of 3 or possibly 4 in the future, wet underfloor heating throughout and we have had a 4KW solar PV system installed of which most of the power is going back to the grid but I'm only paid for 50% which is a bit grinding. The combi will not allow more than 1 outlet to be used without reducing performance considerably.

The boiler we have is a BIASI Riva advance HE 32KW (M110B.32SM/C) which has been surprisingly reliable for the past 4 years

I consider that a heat bank will solve most of the problems above in one hit and as I have an Ariston 300L (contract STI 300 indirect) unvented cylinder sitting in my garage I`m looking at converting it at minimal cost. The primary heat source will be the immersion through one of those boxes of tricks that only uses the electricity that would go back to the grid.

For the record I`m a Part P sparks with plenty of heating control experience and have worked with a mate who's a gas safe plumber for a couple of years so I`m not exactly clueless but my plumber mate has no heat bank or thermal store experience so I`m asking for comments from those with a bit more real life experience with them.

Before I start I am aware of the keep PV as electric argument and that gas is 3 times cheaper etc but batteries are hardly eco friendly when you have to change them every 10 years and if the DNO actually bought meters that could measure PV return current and didn't buy back at less than a quarter of what they sell you electric for per KW, or if I had to buy a heat bank for £3k, I wouldn't be considering this.

That said gas is a dwindling / global warming source of energy and it takes the same power to heat water using either gas or electric; in fact electric water heating is near 100% efficient when gas has heat losses in the exhaust, etc. So I`m still helping to save the planet in my own little way.

Battery storage is an option but I`m waiting for price to come down and batteries to be a bit more long lasting. Until then this is how I intend on using my excess PV power.

I am including gas heating of the store for the dark winter months whilst keeping the increased flow rates required for the showers along with instantaneous combi water heating for the occasional use when we've got a cold tank but the sun is on its way.

I was looking at the problems of mixing a pressurised / sealed heating system with a vented tank and have seen systems with external accumulators, additional pumps etc and I thought why not just use the combi system but keep the return at the delivery temperature via the tank coil so the boiler doesn't fire up unless the tank is under temp.

I'm looking at pre-warming the cold water inlet to the DHW to the boiler so that is more efficient (my boiler wont accept hot water apparently) but I got the impression they (BIASI) don't want to leave themselves open to legionnaires claims and refuse to provide any information on CW inlet temperatures. I`m thinking of a prewarm to 30`C which I can't see hurting anything and legionnaires is not an issue as I`m not storing it.

I am using blending valves and keeping pump speeds low to reduce the return flows as far as possible to reduce turbulence in the tank.

Ok so how am I going to do it?

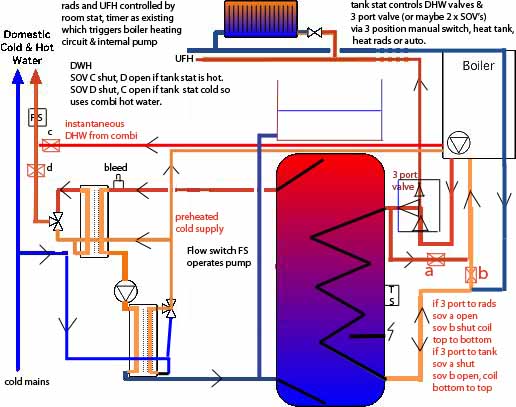

If you look at the schematic I`ll try to talk you through it.

I think the DHW is fairly standard except the tank stat opens and closes the 2 port motorised valves to allow hot water from the tank through a plate heat exchanger the cold water is preheated through a 2nd preheat plate heat exchanger to reduce the return temperature to the bottom of the tank and preheating the combi feed water and the feed to the main plate heat exchanger so a smaller exchanger can be used. The DHW circuit is a direct feed using the hot water in the cylinder to gain maximum heat from the tank. The heating circuit pump is triggered by a flow switch when you open the tap, this flow switch is situated after the combi supply so the preheat works for the combi water even if the tank is not hot enough to heat the water on its own and the combi will use less gas.

The heating is a bit more unusual. There is a 3 position electrical switch (manually operated) ; the positions are `heat rads` - summer position, used when we are confident there will be sun to warm the tank by the immersion the next day; the next is `heat tank` so we have manually decided to heat the tank up as we don't think the sun will be good tomorrow or the sun has not heated it today and we need more than 1 shower in use; the last is `auto` or the winter setting, where the tank stat will heat up the tank using the boiler whenever it cools down to the temperature set on the tank stat.

so there are 3 modes, the first we'll look at is heating with a hot tank.

The boiler receives the heating demand from the room stat and begins the ignition sequence and starts the internal pump. hot water is circulated from the tank through the open motorised valve `a`(SOV `b` is shut) and into the return of the boiler, the boiler will sense the hot water and stop the ignition of the burner, the burner may have already lit by then if everything has cooled down which is a pain but what can you do? (I'm not going to muck around with the boiler extending the time delay between the pump and the ignition start.) The pump will circulate the water around the rads and as SOV `b` is shut it will pass through the coil from bottom to top where it will once again enter the return of the boiler. I've just realised that it needs another blending valve before the return to limit the radiator temperature, I'll blend it with the radiator return where the direction arrows are shown.

Ok now we'll go through a direct combi boiler feed so the tank is under temperature but it's not worth heating 300 litres by gas as the sun will heat it in the morning so the electrical switch is in the summer - heat rads position. The same thing happens and all the valves are in the same positions but the boiler will now sense the return is under the temperature required and fire the boiler, on the way back from the rads the still hot return water will pass through the coil of the cold tank, heating the tank water and ensuring the boiler is condensing. If the tank gets heated by the immersion during this operation the boiler will sense the temperature rise and the boiler will turn off the burner.

The final mode is the heat tank setting, the 3 port valve will turn to open the top of the coil to the boiler output, SOV `a` will shut and SOV `b` will open the flow though the coil will now go from top to bottom extracting as much heat from the water as possible and returning directly to the boiler return through SOV `b`. The return water from the rad circuit will not be able to flow backwards as the 3 port valve will be shut at the front end. If heating is demanded by the room stat the 3 port valve will go to the mid point opening the tank coil and the radiator circuit at the same time, the return from the rads and the return from the bottom of the coil will both flow back to the boiler return through SOV `b`.

Ok so that's how I think it will work but if you've got this far please let me know if you see any problems with the design.

One question i have is the unvented tank has no bleed point, the manual shows an inclined feed tube as I`ve shown but I'm a bit concerned that all the air will not be expelled causing problems, I`m putting the bleed on a long pipe to act as an air collector which can be bled but I also thought of cutting a valve in the top of the tank but how would I attach a flange reliably?

Also I took this diagram from another post and it shows the pump after the heat exchanger, I would have thought it better to push the water rather than sucking it through or am I wrong?

Any assistance on the size, type or best places to get Plate heat exchangers from would be massively welcome.

Thanks in advance to anyone that has spent the time to get this far and makes any suggestions to put my mind at rest.

Tim

I've been studying this and other forums for months off and on and putting all the ideas into a do it all system. I am posting my plans for fitting a heat bank to a combi boiler using a converted 300L unvented cylinder for comments / suggestions and probably ridicule.

First a bit of background.

We are having an extension built which will include 2 additional mixer showers giving a total of 3 or possibly 4 in the future, wet underfloor heating throughout and we have had a 4KW solar PV system installed of which most of the power is going back to the grid but I'm only paid for 50% which is a bit grinding. The combi will not allow more than 1 outlet to be used without reducing performance considerably.

The boiler we have is a BIASI Riva advance HE 32KW (M110B.32SM/C) which has been surprisingly reliable for the past 4 years

I consider that a heat bank will solve most of the problems above in one hit and as I have an Ariston 300L (contract STI 300 indirect) unvented cylinder sitting in my garage I`m looking at converting it at minimal cost. The primary heat source will be the immersion through one of those boxes of tricks that only uses the electricity that would go back to the grid.

For the record I`m a Part P sparks with plenty of heating control experience and have worked with a mate who's a gas safe plumber for a couple of years so I`m not exactly clueless but my plumber mate has no heat bank or thermal store experience so I`m asking for comments from those with a bit more real life experience with them.

Before I start I am aware of the keep PV as electric argument and that gas is 3 times cheaper etc but batteries are hardly eco friendly when you have to change them every 10 years and if the DNO actually bought meters that could measure PV return current and didn't buy back at less than a quarter of what they sell you electric for per KW, or if I had to buy a heat bank for £3k, I wouldn't be considering this.

That said gas is a dwindling / global warming source of energy and it takes the same power to heat water using either gas or electric; in fact electric water heating is near 100% efficient when gas has heat losses in the exhaust, etc. So I`m still helping to save the planet in my own little way.

Battery storage is an option but I`m waiting for price to come down and batteries to be a bit more long lasting. Until then this is how I intend on using my excess PV power.

I am including gas heating of the store for the dark winter months whilst keeping the increased flow rates required for the showers along with instantaneous combi water heating for the occasional use when we've got a cold tank but the sun is on its way.

I was looking at the problems of mixing a pressurised / sealed heating system with a vented tank and have seen systems with external accumulators, additional pumps etc and I thought why not just use the combi system but keep the return at the delivery temperature via the tank coil so the boiler doesn't fire up unless the tank is under temp.

I'm looking at pre-warming the cold water inlet to the DHW to the boiler so that is more efficient (my boiler wont accept hot water apparently) but I got the impression they (BIASI) don't want to leave themselves open to legionnaires claims and refuse to provide any information on CW inlet temperatures. I`m thinking of a prewarm to 30`C which I can't see hurting anything and legionnaires is not an issue as I`m not storing it.

I am using blending valves and keeping pump speeds low to reduce the return flows as far as possible to reduce turbulence in the tank.

Ok so how am I going to do it?

If you look at the schematic I`ll try to talk you through it.

I think the DHW is fairly standard except the tank stat opens and closes the 2 port motorised valves to allow hot water from the tank through a plate heat exchanger the cold water is preheated through a 2nd preheat plate heat exchanger to reduce the return temperature to the bottom of the tank and preheating the combi feed water and the feed to the main plate heat exchanger so a smaller exchanger can be used. The DHW circuit is a direct feed using the hot water in the cylinder to gain maximum heat from the tank. The heating circuit pump is triggered by a flow switch when you open the tap, this flow switch is situated after the combi supply so the preheat works for the combi water even if the tank is not hot enough to heat the water on its own and the combi will use less gas.

The heating is a bit more unusual. There is a 3 position electrical switch (manually operated) ; the positions are `heat rads` - summer position, used when we are confident there will be sun to warm the tank by the immersion the next day; the next is `heat tank` so we have manually decided to heat the tank up as we don't think the sun will be good tomorrow or the sun has not heated it today and we need more than 1 shower in use; the last is `auto` or the winter setting, where the tank stat will heat up the tank using the boiler whenever it cools down to the temperature set on the tank stat.

so there are 3 modes, the first we'll look at is heating with a hot tank.

The boiler receives the heating demand from the room stat and begins the ignition sequence and starts the internal pump. hot water is circulated from the tank through the open motorised valve `a`(SOV `b` is shut) and into the return of the boiler, the boiler will sense the hot water and stop the ignition of the burner, the burner may have already lit by then if everything has cooled down which is a pain but what can you do? (I'm not going to muck around with the boiler extending the time delay between the pump and the ignition start.) The pump will circulate the water around the rads and as SOV `b` is shut it will pass through the coil from bottom to top where it will once again enter the return of the boiler. I've just realised that it needs another blending valve before the return to limit the radiator temperature, I'll blend it with the radiator return where the direction arrows are shown.

Ok now we'll go through a direct combi boiler feed so the tank is under temperature but it's not worth heating 300 litres by gas as the sun will heat it in the morning so the electrical switch is in the summer - heat rads position. The same thing happens and all the valves are in the same positions but the boiler will now sense the return is under the temperature required and fire the boiler, on the way back from the rads the still hot return water will pass through the coil of the cold tank, heating the tank water and ensuring the boiler is condensing. If the tank gets heated by the immersion during this operation the boiler will sense the temperature rise and the boiler will turn off the burner.

The final mode is the heat tank setting, the 3 port valve will turn to open the top of the coil to the boiler output, SOV `a` will shut and SOV `b` will open the flow though the coil will now go from top to bottom extracting as much heat from the water as possible and returning directly to the boiler return through SOV `b`. The return water from the rad circuit will not be able to flow backwards as the 3 port valve will be shut at the front end. If heating is demanded by the room stat the 3 port valve will go to the mid point opening the tank coil and the radiator circuit at the same time, the return from the rads and the return from the bottom of the coil will both flow back to the boiler return through SOV `b`.

Ok so that's how I think it will work but if you've got this far please let me know if you see any problems with the design.

One question i have is the unvented tank has no bleed point, the manual shows an inclined feed tube as I`ve shown but I'm a bit concerned that all the air will not be expelled causing problems, I`m putting the bleed on a long pipe to act as an air collector which can be bled but I also thought of cutting a valve in the top of the tank but how would I attach a flange reliably?

Also I took this diagram from another post and it shows the pump after the heat exchanger, I would have thought it better to push the water rather than sucking it through or am I wrong?

Any assistance on the size, type or best places to get Plate heat exchangers from would be massively welcome.

Thanks in advance to anyone that has spent the time to get this far and makes any suggestions to put my mind at rest.

Tim