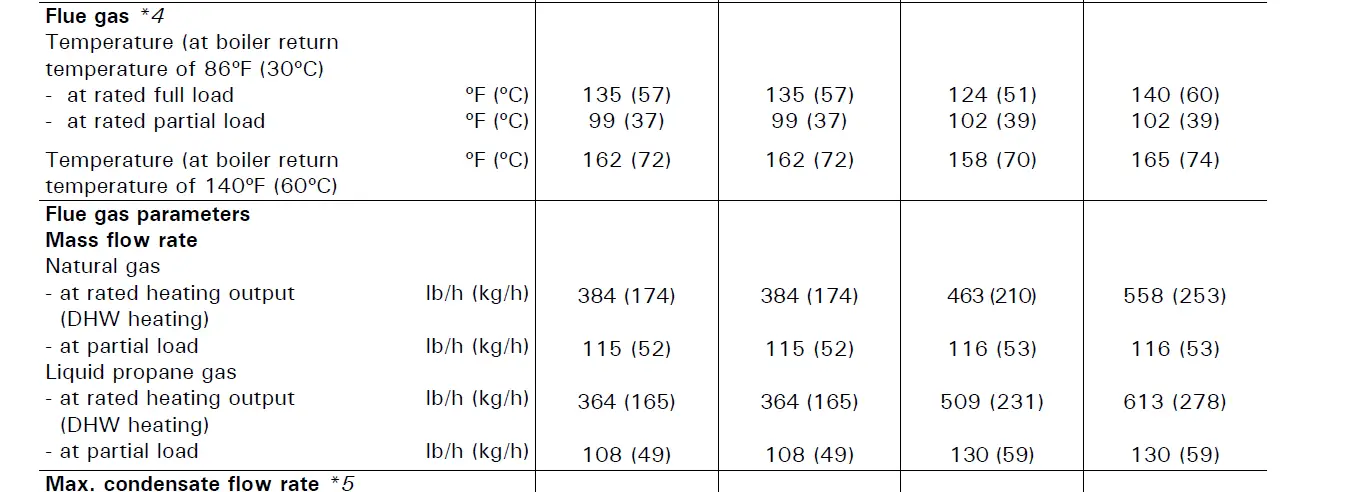

I have seen numbers recently on some gas boiler manual where I think it showed that at full firing, the flue gas temperature was ~ 45/55C higher (its actually only 27C higher) than the return temp and if this is say 35/45C then as some of the gases will be in contact with the combustion chamber then some condensing will take place IMO. On minimum output the gases I think were within 10C (actually 7C) of the return water temperature. It would be well worth for someone with a gas boiler whose interested to actually measure the condensate flow at various boiler outputs and return temperatures.

from page 5 of attachment.

from page 5 of attachment.

Attachments

Last edited: