- Joined

- 5 Dec 2012

- Messages

- 927

- Reaction score

- 13

- Country

I have sloping floors (approx 1.5 - 2 inch slope over a 3 metre span) which i believe is due to historical subsidence. The house was built in 1902.

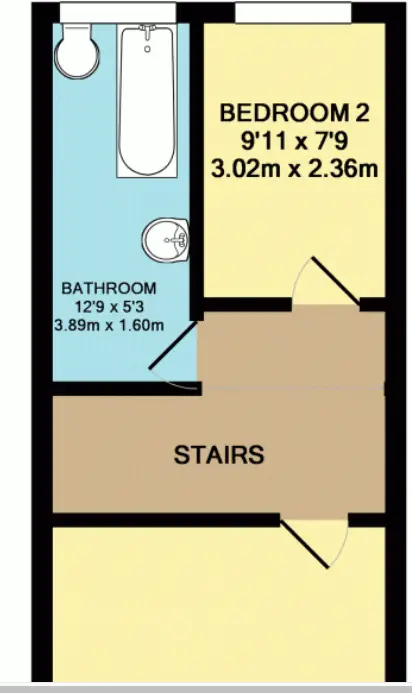

Here is a pic of my floorplan with the sloping area of concern. It was a 2 up 2 down however they have now had stud walls put in to create a smaller bedroom and a bathroom, as per floor plan.

The slope stairs at the top of the stairs, and slopes in the direction of 'bedroom 2', and also the bathroom. So effectively, as it used to be, the whole of the back of the house slopes.

I intend on taking out the floorboards and exposing joists, sistering the joists level, and reinstating the floor.

The joists run from front to back of the upstairs house, and the floorboards from L - R

My main questions are:

1. If i have to raise the floor and the point at which it raises means that the finished floor will be messing about with the door frames, do you shave the door frame in situ or take them off?

2. Would you re-lay the floor (typial floor boards) or would you install somthing such as moisture resistant loftboard instead?

3. Any issues that may present themselves to me that i may have not noticed?

4. Seems a stupid question, but are the stud walls okay to be left in or do i have to take them out to have an open area of joists?

5. Probably my most important question - Do i start levelling at the top of the stairs / landing area and work from there - the slope moves away from the stairs so it will be the high point.

Thanks

Here is a pic of my floorplan with the sloping area of concern. It was a 2 up 2 down however they have now had stud walls put in to create a smaller bedroom and a bathroom, as per floor plan.

The slope stairs at the top of the stairs, and slopes in the direction of 'bedroom 2', and also the bathroom. So effectively, as it used to be, the whole of the back of the house slopes.

I intend on taking out the floorboards and exposing joists, sistering the joists level, and reinstating the floor.

The joists run from front to back of the upstairs house, and the floorboards from L - R

My main questions are:

1. If i have to raise the floor and the point at which it raises means that the finished floor will be messing about with the door frames, do you shave the door frame in situ or take them off?

2. Would you re-lay the floor (typial floor boards) or would you install somthing such as moisture resistant loftboard instead?

3. Any issues that may present themselves to me that i may have not noticed?

4. Seems a stupid question, but are the stud walls okay to be left in or do i have to take them out to have an open area of joists?

5. Probably my most important question - Do i start levelling at the top of the stairs / landing area and work from there - the slope moves away from the stairs so it will be the high point.

Thanks