- Joined

- 2 Aug 2019

- Messages

- 68

- Reaction score

- 2

- Country

Hi, would be grateful for any info or links to help me with a design for an extension to the rear of a cuboid house.

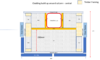

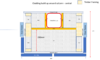

The extension consists of six brick (clad) pillars (reinforced with steel columns), horizontal beams, a flat roof terrace and sliding doors. Bordering the underside of the roof terrace are black fascia covering joists/insulation/potenially bricks/blocks etc.

It is this latter bit I am struggling with. I have the design details where you have bricks or blocks behind the fascia tied into the pillars, with these built on a plate welded to the beams (or a premanufactured equivalent).

But is there an option where you simply use, say, a structured, relatively lightweight insulated material to sit above the doors and in front of the beam in an energy efficient manner (ie no cold bridges). Spans are around 3.5m.

The extension consists of six brick (clad) pillars (reinforced with steel columns), horizontal beams, a flat roof terrace and sliding doors. Bordering the underside of the roof terrace are black fascia covering joists/insulation/potenially bricks/blocks etc.

It is this latter bit I am struggling with. I have the design details where you have bricks or blocks behind the fascia tied into the pillars, with these built on a plate welded to the beams (or a premanufactured equivalent).

But is there an option where you simply use, say, a structured, relatively lightweight insulated material to sit above the doors and in front of the beam in an energy efficient manner (ie no cold bridges). Spans are around 3.5m.