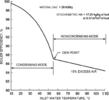

As johntheo5 said, that is true with regards to oil. Net/Gross figures which are the difference between heat of burning the fuel vs heat of burning + latent heat of water produced by combustion products are where condensing appliances get their additional efficiency from if running at optimum temperatures. The likes of burning Hydrodgen directly (which the main combustion product is water) gives around a potential for 18% additional energy if its fully condensing.

As far as the origional post goes. Ideally the lower temperature you can run at the better, this is where Weather Compensation Controls make a big difference. However as you have a system boiler you need a flow hot enough to heat the cyclinder, and while the chances of legionaries disease is low in domestic properties anyway, its not zero, so really heating the cylinder above 60 is recommended, at least once a week, but without controls that can automatically do that then it becomes a bit of a pain.

Have a look into what worscter offer regarding controls, I'm not familiar with any of their newer stuff. But Good condensing system boilers should have the option to have a manufacturers control that can run higher temp to the cylinder, then run lower temp to the radiators, and weather compensation only runs the tempearture required to the radiators, ie in the dead of winter it may use 60 degree flow, but as the weather gets better and you need less heat put into the house it will automatically reduce the flow tempeature.