You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flow rate in central heating system

- Thread starter edb49

- Start date

In my first post I suggested that a cheaper solution would be to fit install a low loss header, with the UPS25-55 in the primary loop and an Alpha 2 in the secondary.

The alternative, fitting a larger pump has problems of its own. If you fit a UPS 32-60 your consumption will be about 830kWH pa (Grundfos estimate) and there is still a danger that the boiler will not be running at the correct temperature/flow rate as you are limited to running "on the curve".

If you fit a Magna 25-60 your consumption will be 249kWH pa (Grundfos est) but you will run at the correct temperature/flow rate. The cost is however much higher.

An Alpha 2L pump will cost about £100 and a low loss header about the same. This is less than the cost of a UPS32-60 (£300+) or a Magna 25-60 (£470+).

The alternative, fitting a larger pump has problems of its own. If you fit a UPS 32-60 your consumption will be about 830kWH pa (Grundfos estimate) and there is still a danger that the boiler will not be running at the correct temperature/flow rate as you are limited to running "on the curve".

If you fit a Magna 25-60 your consumption will be 249kWH pa (Grundfos est) but you will run at the correct temperature/flow rate. The cost is however much higher.

An Alpha 2L pump will cost about £100 and a low loss header about the same. This is less than the cost of a UPS32-60 (£300+) or a Magna 25-60 (£470+).

Will reply later - I have just been "asked" to go out by SWMBO.

- Joined

- 19 Feb 2006

- Messages

- 31,753

- Reaction score

- 11,349

- Country

Do not fit a variable as a primary pump to these boilers it will still give s codes.

No point fitting an 11/4port to inch pipe the 25port pump is right for your setup.

Low loss is always going to work by removing the boiler head from the system but means mote electrics controls.Vaillant llh 45kw is the nest one for you but dh price is way out.

Practicle experience also needed one these as well as theory.

You want to save money by fitting a a rate variable you'll have to have a low loss

No point fitting an 11/4port to inch pipe the 25port pump is right for your setup.

Low loss is always going to work by removing the boiler head from the system but means mote electrics controls.Vaillant llh 45kw is the nest one for you but dh price is way out.

Practicle experience also needed one these as well as theory.

You want to save money by fitting a a rate variable you'll have to have a low loss

Do not fit a variable as a primary pump to these boilers it will still give s codes.

No point fitting an 11/4port to inch pipe the 25port pump is right for your setup.

Low loss is always going to work by removing the boiler head from the system but means mote electrics controls.Vaillant llh 45kw is the nest one for you but dh price is way out.

Practicle experience also needed one these as well as theory.

You want to save money by fitting a a rate variable you'll have to have a low loss

The Magna 25-60 and 25-100 seem to be fundamentally more efficient than the UPS series, even when running at a constant output. So they are probably more economical pumps to go for over a longer term, which is what I'm thinking about. (This is why I'm thinking about a Magna, not because I want a varaible rate pump.)

Will reply later - I have just been "asked" to go out by SWMBO.

Thanks

Why?Do not fit a variable as a primary pump to these boilers it will still give s codes.

Why?Do not fit a variable as a primary pump to these boilers it will still give s codes.

I assume that this would be caused as the house gets up to temperature, valves close, head reduces, the pump speed drops and temperature delta across the heat exchanger increases above the defined limits. (Or maybe I mean valves are open in a cold house, and head is small.)

This assumes that your original boiler Mexico boiler was working correctly.Can I ask how you have calculated the Magna 25-60 would be sized correctly?

From the Mexico manual the output is 36.6kW so at an 11C drop the flow rate is 36.6/(4.2 x 11) = 0.79 l/sec (47.5 l/min, 2.85m³/hr). From the flow rate/pressure loss graph on page 7 of the manual we find that at that rate the boiler loss is about 110 mbar.

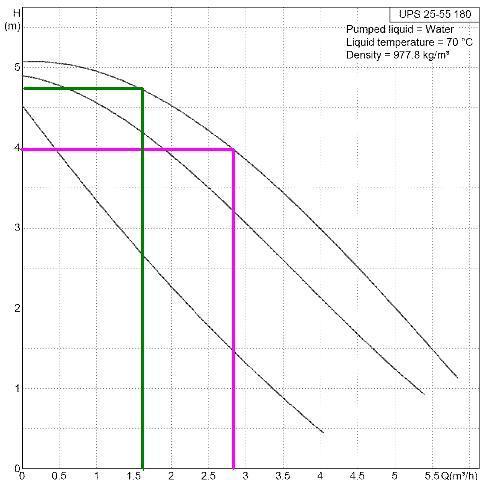

This graph shows the Mexico data plotted as the purple line

At the required flow rate the head will be 4m or approx 400mbar. We know that the boiler loss is 110 mbar, so the loss though the rest of the system must be 400-110= 290mbar.

Now pressure loss is approximately proportional to the flow rate squared. We know that the flow rate of the Ultrcom at max output is 1.633 m³/hr, so the circuit pressure will reduce to approx 290 x (1.633/2.85)² = 95 mbar.

The loss through the Ultracom is 4.05m or approx 400 mbar so the total loss is 400+95 =495mbar, say 500 mbar or 5 m. The green line shows that at the required flow rate the pump can only deliver 4.75 metres, so the flow rate decreases until it can it deliver 5m.

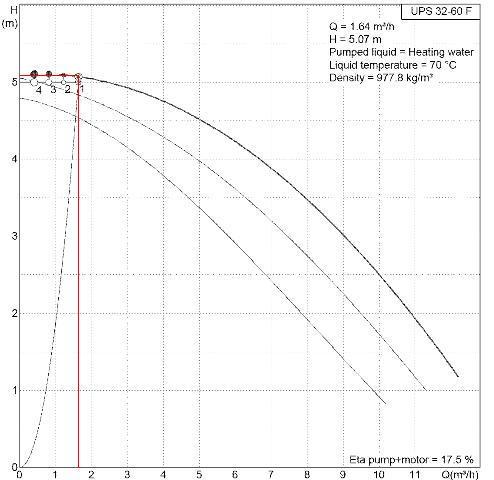

If we now put the new boiler data (flow=1.633, head = 5m) into Grundfos's sizing tool is comes up with either the UPS 32-60 or the Magna 25-60. The left graph shows the data plotted for the UPS, the right for the Magna. You will see that the Magna has plenty of spare capacity to cope with higher pressure, if necessary. The UPS suffers from the complaint of all fixed speed pumps - you have to run on the curve all the time. The numbers 1,2 3 and 4 show how the pump operates under reduced load at various times of the year.

You mentioned constant pressure control. Grundfos only recommend this for systems with a relatively low small head losses. The recommended setting for high losses is either Autoadapt or proportional pressure.

Unlike the UPS type pumps, the Magna does not have fixed speeds, the speed electronically controlled by sensors which measure the flow temperature and differential pressure.

Hope that's enough info.

On the question of balancing, the system will have been balanced for an 11C differential. Because the pressure has changed all round the system, due to the reduced flow rate and higher head of the pump, the current balancing will no longer be correct.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 13

- Views

- 5K

- Replies

- 40

- Views

- 11K

- Replies

- 15

- Views

- 6K

- Replies

- 4

- Views

- 1K

- Replies

- 159

- Views

- 19K