The 1mb is total all sections.

AS GW said if the Kw posted is outputs and the range is under estimated, you will need 35mm to the branch, although without doing the calcs it would be close if the last section to the boiler was 28mm.

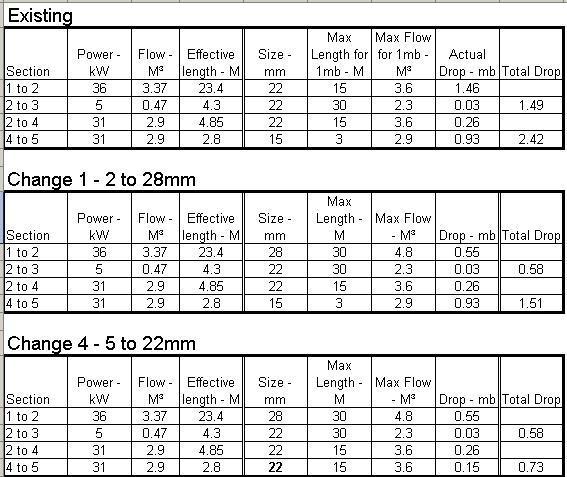

So 28mm from the meter to the boiler and 22mm to the range. I may do the workings later, if I get bored.

AS GW said if the Kw posted is outputs and the range is under estimated, you will need 35mm to the branch, although without doing the calcs it would be close if the last section to the boiler was 28mm.

So 28mm from the meter to the boiler and 22mm to the range. I may do the workings later, if I get bored.