hi all,

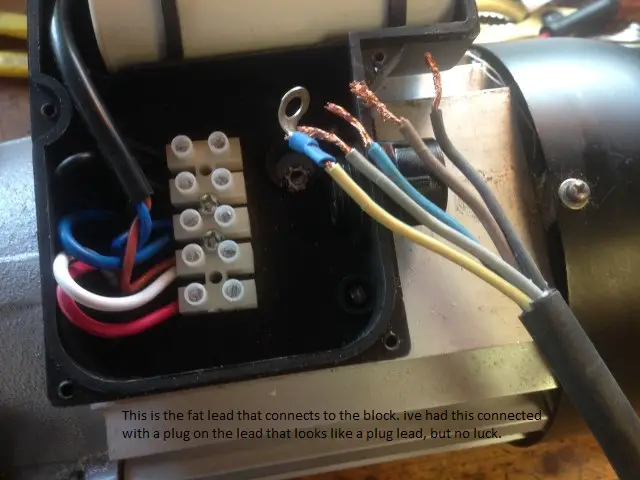

i was given this motor free of charge from a member on the site and apparently its off of a record planer/thicknesser.

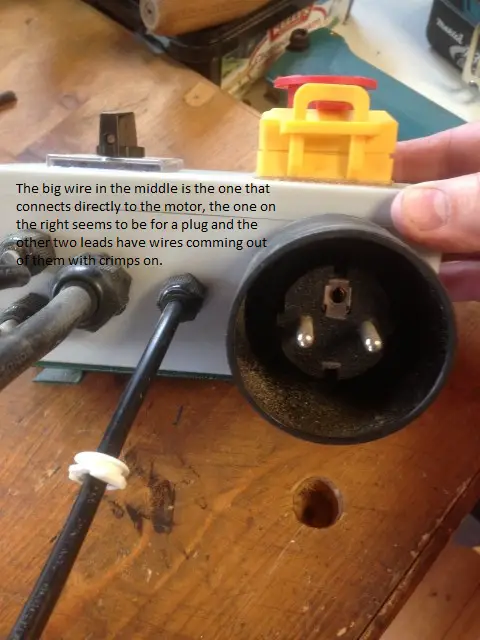

as you can see in the pictures it has an NVR switch.

there is 4 wires comming from the NVR and i was hoping someone would point me in the right direction in how to wire this up properly.

even if i cant use the NVR, is there a way to just connect a normal plug to it to power it .

hope you can help

thanks

chris....

i was given this motor free of charge from a member on the site and apparently its off of a record planer/thicknesser.

as you can see in the pictures it has an NVR switch.

there is 4 wires comming from the NVR and i was hoping someone would point me in the right direction in how to wire this up properly.

even if i cant use the NVR, is there a way to just connect a normal plug to it to power it .

hope you can help

thanks

chris....