Hey all,

Long time lurker first time poster. Never had the need to post really as I've managed to find everything i need via search, until now lol.

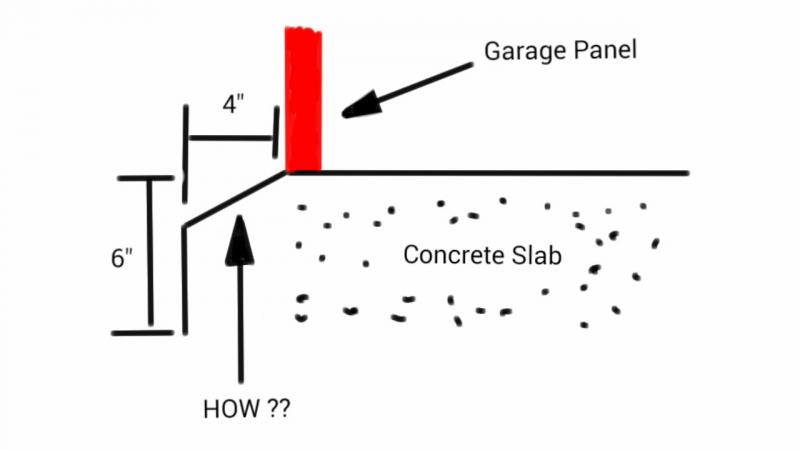

Basically I'm laying a concrete slab for my soon to be erected sectional concrete garage. I've read a lot about the dreaded water ingress under the panels. I'm trying to design a solution into the slab instead of trying to fix once I get leaks.

If i can get the exact measurements of the garage, and i mean exact, would i be able to put a chamfer on the bases edge? Just like in my crap drawing below?

I'm thinking of just nailing some 4" wedges to the edge of the shuttering but I'm afraid they wont stay square and level once i start to level off the concrete. I intend to use the traditional method of a straight piece of wood across the edges of the shuttering to level it all off.

Am i over thinking this??

Cheers guys

Steve

Long time lurker first time poster. Never had the need to post really as I've managed to find everything i need via search, until now lol.

Basically I'm laying a concrete slab for my soon to be erected sectional concrete garage. I've read a lot about the dreaded water ingress under the panels. I'm trying to design a solution into the slab instead of trying to fix once I get leaks.

If i can get the exact measurements of the garage, and i mean exact, would i be able to put a chamfer on the bases edge? Just like in my crap drawing below?

I'm thinking of just nailing some 4" wedges to the edge of the shuttering but I'm afraid they wont stay square and level once i start to level off the concrete. I intend to use the traditional method of a straight piece of wood across the edges of the shuttering to level it all off.

Am i over thinking this??

Cheers guys

Steve