Hi

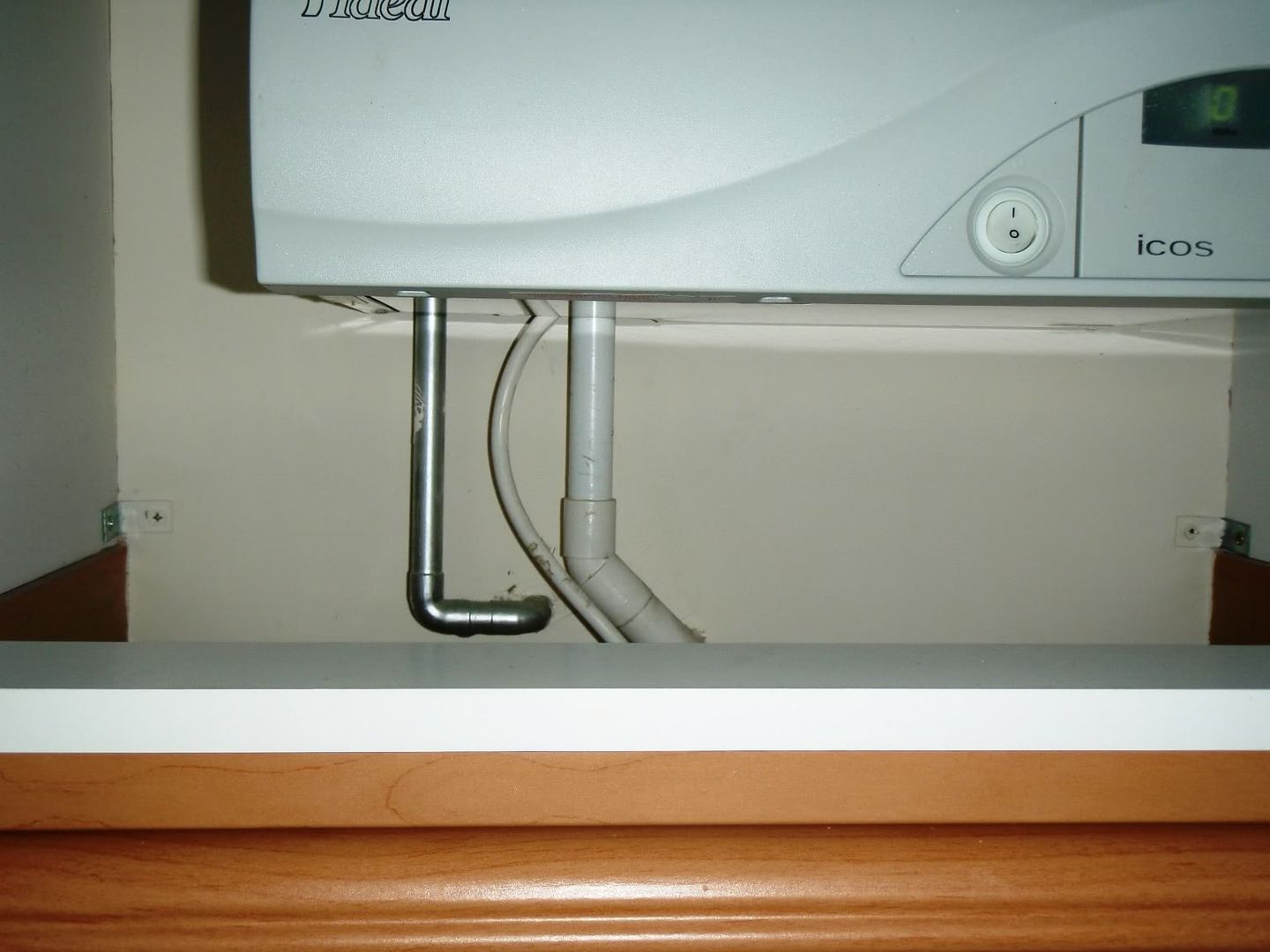

My recent house has an ICOS HE15 boiler with a Santon Premier Plus pressurised system.

After problems with 'L' 'F' flashiong I have removed and cleaned the condense trap which has now fixed that.

However just above the boiler in the pipework is a pressure gauge and release valve, currently showing about 0.3 bar!!!

I can not find any obvious way to top up the system and the installation manual is of no help.

Could somebody please quide me in the right direction?

I did wonder if it would re-pressurise itself once I had the boiler running again but it hasn't! My neighbours is at just over 1bar pressure and working fine. The only pipes to the boiler are 2 large pipes in and out, and the condense trap. The overflow/pressure is off one of the large pipes.

Any advice/suggestions gratefully accepted.

My recent house has an ICOS HE15 boiler with a Santon Premier Plus pressurised system.

After problems with 'L' 'F' flashiong I have removed and cleaned the condense trap which has now fixed that.

However just above the boiler in the pipework is a pressure gauge and release valve, currently showing about 0.3 bar!!!

I can not find any obvious way to top up the system and the installation manual is of no help.

Could somebody please quide me in the right direction?

I did wonder if it would re-pressurise itself once I had the boiler running again but it hasn't! My neighbours is at just over 1bar pressure and working fine. The only pipes to the boiler are 2 large pipes in and out, and the condense trap. The overflow/pressure is off one of the large pipes.

Any advice/suggestions gratefully accepted.