Hi all.

Just hoping for some pointers.

I've been putting this off for along time now but need to bite the bullet as it were.

Right, the light blue will be new doors

Dark blue will need to be new brickwork as the doors do no span to the original width of window

Green is existing concrete lintel on inner skin

Yellow will be new lintel

Red line is where the joist are inside.

So my thinking is this.

Acro inside every 2-3ft with board to support the joist.

Then outside, acros with strong boys going in 1 skin or as far as possible?

Once all supported, remove window and brick up left hand side - keying is where possible.

*Should I brick to the finished required width, or go wider and cut it back with diamond saw when I cut the brickwork below?

Once that is bricked up, how long can I wait before placing new lintel on new brick work?

Remove 2 course of bricks for new lintel.

Does lintel sit directly on brick or do I bring it up to meet the course above and pack with slate then motar?

Other question.

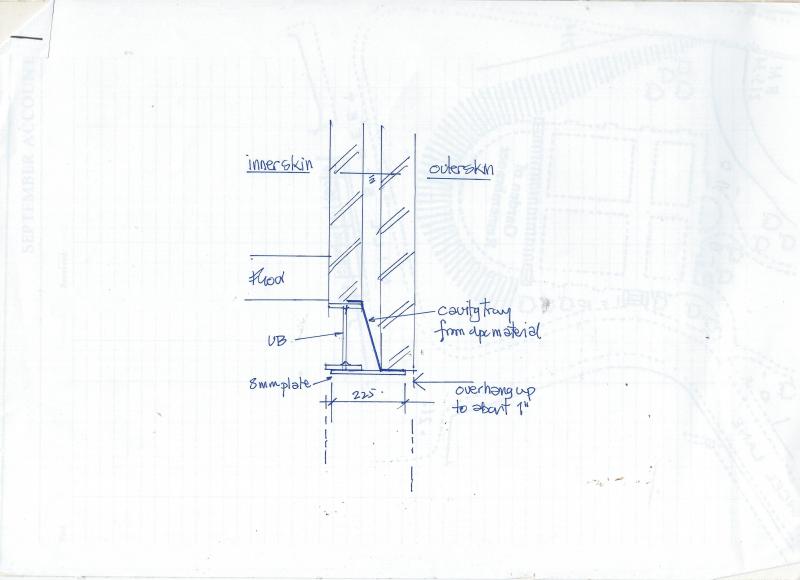

I have been given calcs for a UB or a Catnic.

UB works out cheaper but all he said is the size with a 8mm plated welded for the bricks to sit on but no size of the bricks.

So I presume the plate it brick + cavity + brick on the bottom of the I ?

Where does the UB site in relation to depth. ie. straddling both inner and outer skin?

I have more question but can not remember these at the moment.

Other info, I have got BC involved and approved, I have had quotes for thie work ranging from £800 - £2000

Money is high priority and I don't like paying for work I feel very capable of doing myself

Thanks inadvance

Just hoping for some pointers.

I've been putting this off for along time now but need to bite the bullet as it were.

Right, the light blue will be new doors

Dark blue will need to be new brickwork as the doors do no span to the original width of window

Green is existing concrete lintel on inner skin

Yellow will be new lintel

Red line is where the joist are inside.

So my thinking is this.

Acro inside every 2-3ft with board to support the joist.

Then outside, acros with strong boys going in 1 skin or as far as possible?

Once all supported, remove window and brick up left hand side - keying is where possible.

*Should I brick to the finished required width, or go wider and cut it back with diamond saw when I cut the brickwork below?

Once that is bricked up, how long can I wait before placing new lintel on new brick work?

Remove 2 course of bricks for new lintel.

Does lintel sit directly on brick or do I bring it up to meet the course above and pack with slate then motar?

Other question.

I have been given calcs for a UB or a Catnic.

UB works out cheaper but all he said is the size with a 8mm plated welded for the bricks to sit on but no size of the bricks.

So I presume the plate it brick + cavity + brick on the bottom of the I ?

Where does the UB site in relation to depth. ie. straddling both inner and outer skin?

I have more question but can not remember these at the moment.

Other info, I have got BC involved and approved, I have had quotes for thie work ranging from £800 - £2000

Money is high priority and I don't like paying for work I feel very capable of doing myself

Thanks inadvance