When fixing MCBs in a CU do not use a magnetised screwdriver for the bus bar clamp screw. Or if you do use something non magnetic to push the screw back into the MCB if it has come forward stuck magnetically to the screw driver as it is removed.

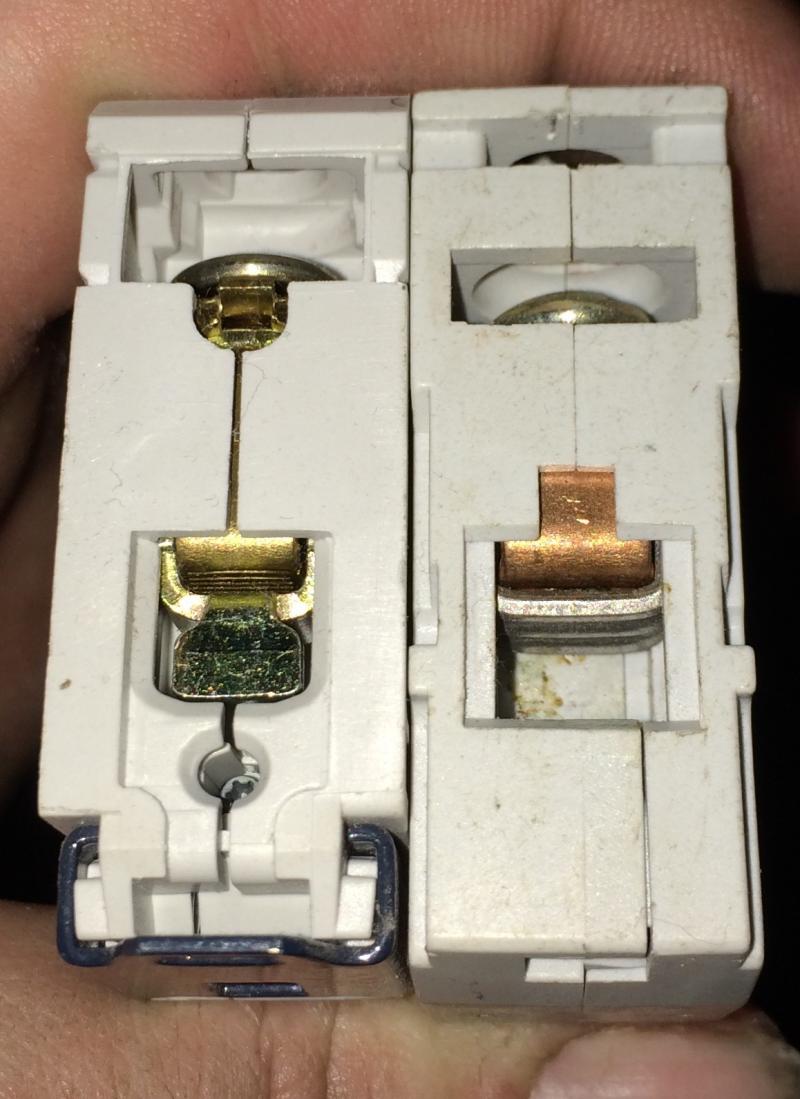

If the screw isn't pushed back then the clamp in the MCB remains closed and the tongue of the bus bar goes behind the clamp instead of into the clamp. As a result the tongue is not clamped when the screw is tightened.

The bus bar is pulled forward by the clamps in adjacent MCBs ( assuming those tongues are in the clamps ) so the tongue that is not in the clamp is pulled forward and presses against the back of the clamp. It makes electrical contact and thus the circuit appears to work and it seems also test as being properly clamped.

If the screw isn't pushed back then the clamp in the MCB remains closed and the tongue of the bus bar goes behind the clamp instead of into the clamp. As a result the tongue is not clamped when the screw is tightened.

The bus bar is pulled forward by the clamps in adjacent MCBs ( assuming those tongues are in the clamps ) so the tongue that is not in the clamp is pulled forward and presses against the back of the clamp. It makes electrical contact and thus the circuit appears to work and it seems also test as being properly clamped.