Hi all,

Wanted to replace the faceplate but when I've gone to attach acrew it back in the thread has gone on both sides, can't get any purchase whatsoever.

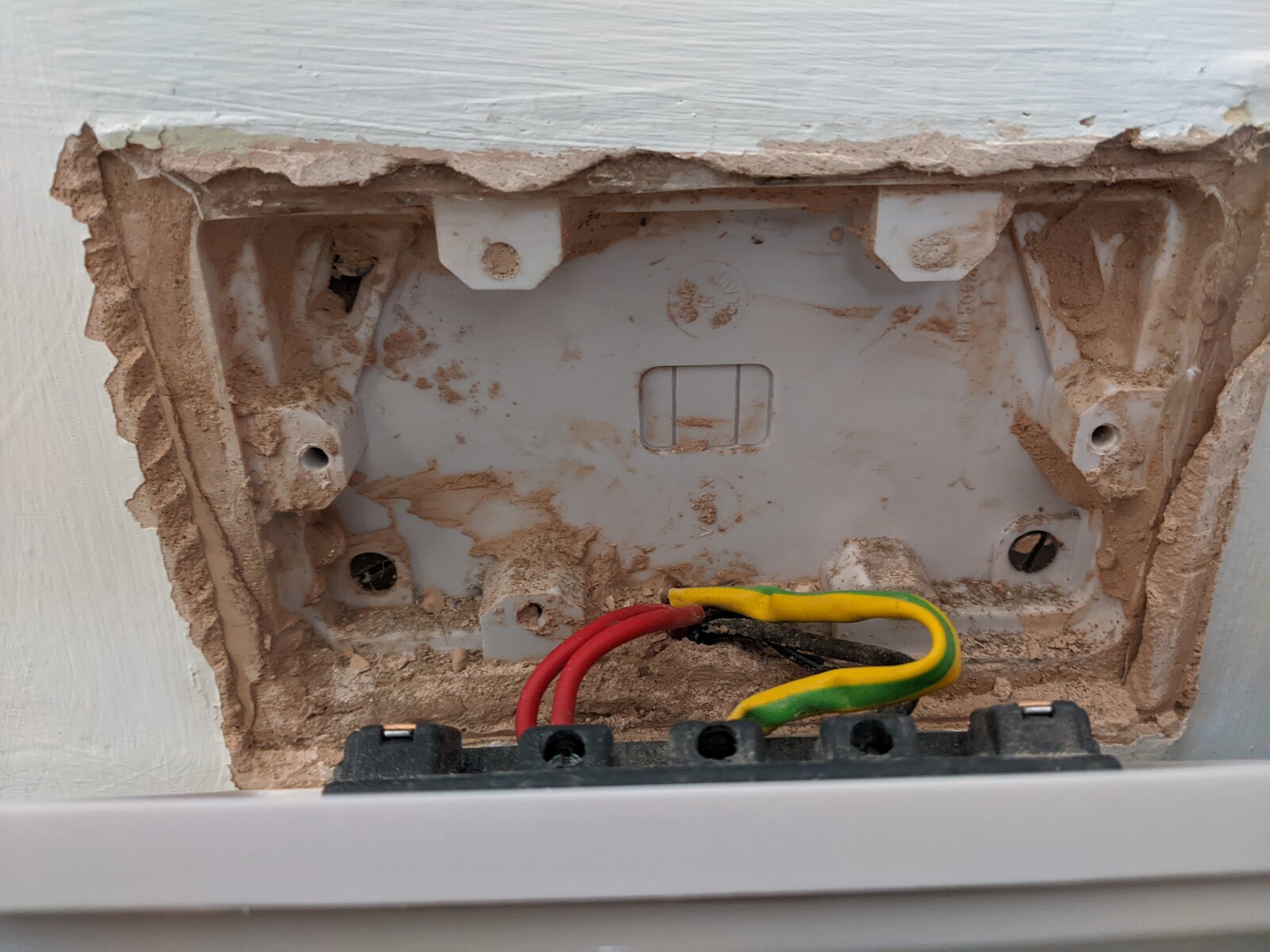

Most of the advice on repairs I can find online seems to be for metal backboxes but this one is plastic - please see attached picture (most of the backboxes in the house were in this unfortunate state when we bought it).

Not sure if there is enough material left to retap as the hole seems quite wide- is it actually possible to retap a plastic backbox?

Any ideas on how I might be able to fix this without getting the backbox replaced?

Thanks in advance for your advice.

Wanted to replace the faceplate but when I've gone to attach acrew it back in the thread has gone on both sides, can't get any purchase whatsoever.

Most of the advice on repairs I can find online seems to be for metal backboxes but this one is plastic - please see attached picture (most of the backboxes in the house were in this unfortunate state when we bought it).

Not sure if there is enough material left to retap as the hole seems quite wide- is it actually possible to retap a plastic backbox?

Any ideas on how I might be able to fix this without getting the backbox replaced?

Thanks in advance for your advice.