Hi everyone, it's your favourite electrician's mate here!

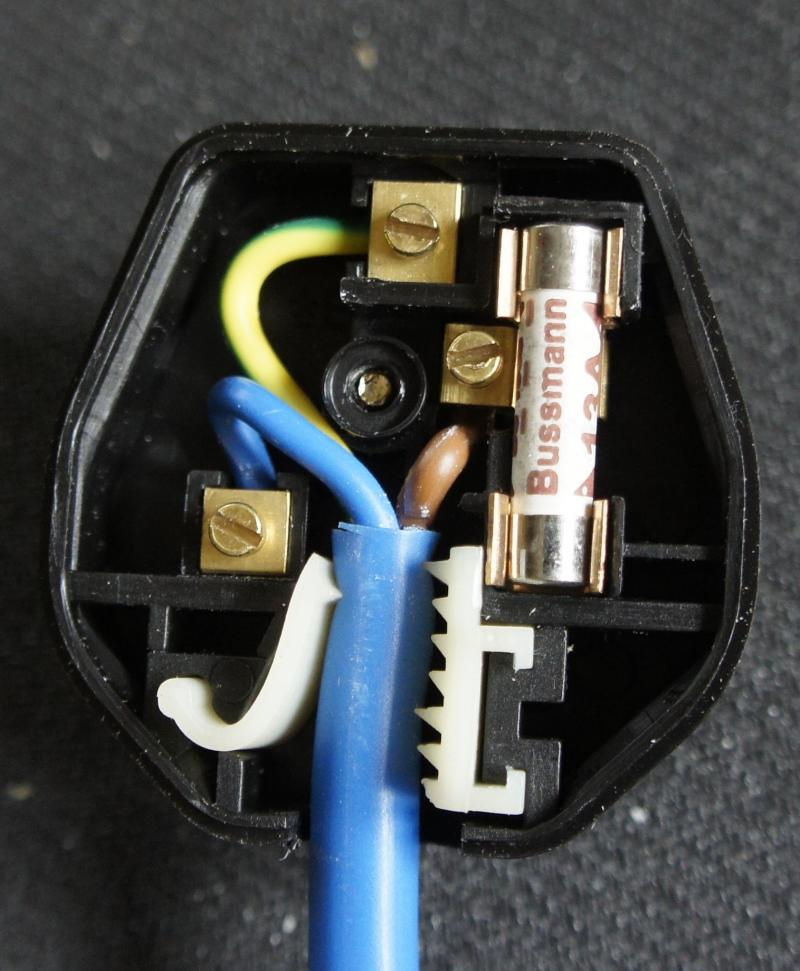

When it comes to trimming the sheath on a cable and trimming the wires to length for use inside a plug, is there a faster way to do it than by hand and cutting the sheath, measuring each wire, cutting to length, leaving enough cable at the end and so on?

I mean, let's say you were a factory owner and wanted to put a plug on a cable 100 times a day, wouldn't you want a machine that you could set up so that all you had to do was shove the cable in and something inside the machine would grab hold of the sheath, then you pull it out and it would be cut exactly how you wanted it?

You might then put the three wires in and the wonder machine would do the same to them, and they would each come out at the perfect length?

Ok, so I don't need to wire a plug 100 times a day, I just wonder if there is such a machine?

When it comes to trimming the sheath on a cable and trimming the wires to length for use inside a plug, is there a faster way to do it than by hand and cutting the sheath, measuring each wire, cutting to length, leaving enough cable at the end and so on?

I mean, let's say you were a factory owner and wanted to put a plug on a cable 100 times a day, wouldn't you want a machine that you could set up so that all you had to do was shove the cable in and something inside the machine would grab hold of the sheath, then you pull it out and it would be cut exactly how you wanted it?

You might then put the three wires in and the wonder machine would do the same to them, and they would each come out at the perfect length?

Ok, so I don't need to wire a plug 100 times a day, I just wonder if there is such a machine?