I need to change out some chipboard flooring in the bathroom as its rotten due to moisture. The joists are at 600mm centres and the current flooring is 620MM wide (not sure on the thickness yet). The problem I have is both of the boards that need replacing go all the way under a partition wall so cant swap the whole board out.

The areas that I need to replace due to rotting will be able to go across the three joists that span the bathroom. I am planning on cutting out the original board just short of the joist and once most of the board is out I can then fine tune and remove the rest that sits on the joist itself. This can then be replaced by a fresh piece of floor and butt up to the other board on the joist. Is this ok to do with these boards or would they need extra support as they are not interlinking with the other board anymore on the joist as I will need to cut out the tongue from the other board to fit it in the space. The joists are I-Joist design and planning on screwing them down with minimum size 8 screws and not less than twice the thickness of the board I am using.

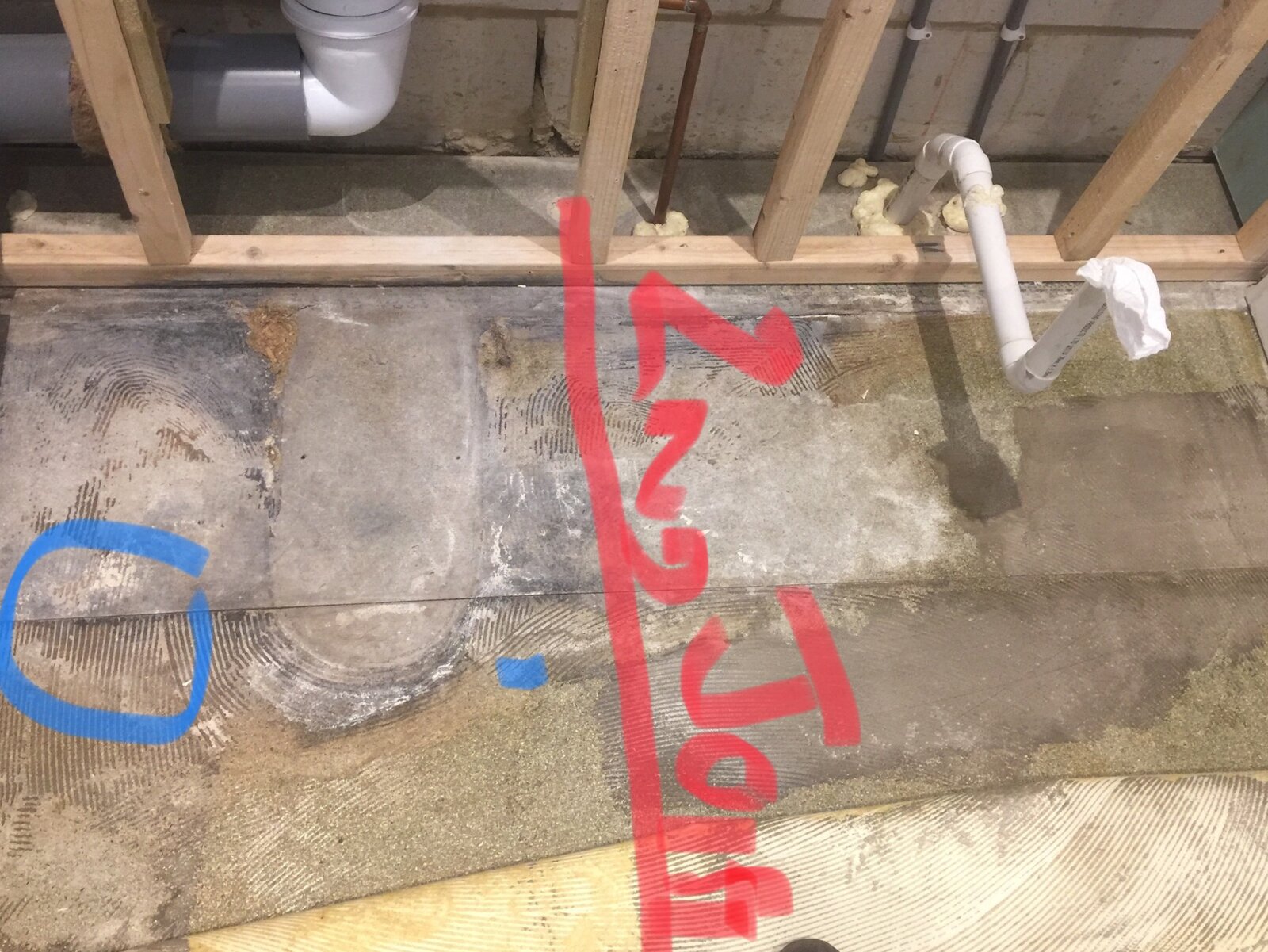

1st picture showing joist centres (red lines) with partition wall on the right. The first board under the waste pipe starts just under the tiles visible under the bath and goes all the way under the partition wall. I am planning on cutting this up to the third joist shown in the picture and relaying the replacement panel on this joist.

Second picture shows the first board where it joins together on the first joist.

Annoyingly the second floor panel in this picture is generally ok but there is a lip on the joins of around 5mm (blue circle) where the floor has warped so I was thinking of cutting this panel out and laying it on the second joist in the third picture (just to the right of the waste pipe) attached.

Thanks for looking any advice/suggestions welcome!

The areas that I need to replace due to rotting will be able to go across the three joists that span the bathroom. I am planning on cutting out the original board just short of the joist and once most of the board is out I can then fine tune and remove the rest that sits on the joist itself. This can then be replaced by a fresh piece of floor and butt up to the other board on the joist. Is this ok to do with these boards or would they need extra support as they are not interlinking with the other board anymore on the joist as I will need to cut out the tongue from the other board to fit it in the space. The joists are I-Joist design and planning on screwing them down with minimum size 8 screws and not less than twice the thickness of the board I am using.

1st picture showing joist centres (red lines) with partition wall on the right. The first board under the waste pipe starts just under the tiles visible under the bath and goes all the way under the partition wall. I am planning on cutting this up to the third joist shown in the picture and relaying the replacement panel on this joist.

Second picture shows the first board where it joins together on the first joist.

Annoyingly the second floor panel in this picture is generally ok but there is a lip on the joins of around 5mm (blue circle) where the floor has warped so I was thinking of cutting this panel out and laying it on the second joist in the third picture (just to the right of the waste pipe) attached.

Thanks for looking any advice/suggestions welcome!