Yes, I think what we are saying is that it is comforting to find that R1 and Rn are substantially equal and R2 is substantially 1.67 times or whatever ratio is appropriate for the conductor size used, if all three readings fall pretty much in alignment it gives a confidence boost

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ring Continuity Test

- Thread starter Jupiter01

- Start date

Indeed - as I wrote early on ....Sometimes a "good" Earth continuity test can be masking a serious double fault in the CPC

However ....There's not really anything practical one can do about it, but one consequence of the issues being discussed above is that, in an existing installation, it is probably rarely, if ever, possible to be certain, by measurement, that the CPCs of the wiring are all intact and that the CPCs are all satisfactorily terminated.

There could be one or more breaks of the CPCs within cables (or their terminations) yet, if 'parallel paths' were present, one could get perfectly credible and reasonable 'continuity measurement' results.

If one measures the resistance from every socket to 'an effective earth' (or, at least, the MET) then one will indeed be able to be confident that, at that point in time, there is an adequate (i.e. 'safe') connection to earth from each socket. HOWEVER, that does not in any way prove that the CPCs in the cable (and their connections) are intact, since the (currently) 'satisfactory' connections from sockets to earth might be via 'parallel paths' - which, at least in theory, might not necessarily be there for ever, something which might be of concern to a very risk-averse person.If there is any doubt about the measured R of the CPC then a wander lead should be used to verify that each and every socket has an effective Earth

Kind Regards, John

Whoops. I hope I`m not seen as a "Clever Cloggs" .....

Goodness, I think you are being over-sensitive. I'm not very easily offended at the best of times, but I didn't even consider 'being offended' by anything you have written in this thread.So if I have offended John or anyone else then I am sorry, it was never my intention.

If it's any consolation, you are one of the last people here whom I would accuse of being a "Clever Cloggs" - I was thinking of those who have a very good knowledge of (and maybe 'worship') what all of the words in 'the regs' say (and don't say) but have a less impressive ability to think - like those who complain about 4mm unfused spurs from ring finals feeding multiple sockets.

...and I think exactly the same of you - and I am certainly (very!) capable of being guilty of typos, as well, sometimes, of true 'errors of thinking' (of facts) - so I'll never be offended by people questioning what I have written!.... I saw what I thought might be a typo and mentioned it to John (I have learned to respect John and his posts so much that I did a recheck on my calculator using 2.5 to 1.5 ratios just to remind myself).

However, we have unearthed something a little odd. Goodness knows where all the sources (including BS 7671) get their figures from. but if a given manufacture were to publish figures indicating conductor resistances for a range of cable sizes which were not (exactly) inversely proportional to their alleged CSAs, that would surely indicate that some of their conductors did not have the intended CSAs.

Somewhat 'worse' than that, there are always going to be small manufacturing tolerances (in CSA), but one would expect/presume that the figures (for resistance) they published would relate to the nominal/'target'/typical/average/whatever CSA - so IF their resistance figures were not inversely proportional to CSA, that would seem to imply that they had 'deliberately' manufactured conductors with 'incorrect' (target/typical/whatever) CSAs.

The deviations from 'expected' we've been discussing are clearly not large enough to be of much practical consequence, but it would be interesting to know why they exist. As SUNRAY has pointed out, they cannot all be explained solely on the basis of rounding.

Kind Regards, John

It seems impossible to find a definitive value of a particular wire to start from.

Sites vary significantly in their figures.

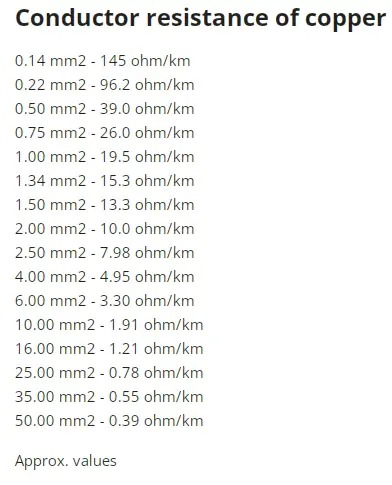

This one comes up first on my search but as you can see very few of the values on the same site match.

Strangely, though, the 2.5:1.5 is spot on - but even the 1:10 isn't and both are higher than usual.

https://www.macartney.com/what-we-o...l-information/conductor-resistance-of-copper/

Sites vary significantly in their figures.

This one comes up first on my search but as you can see very few of the values on the same site match.

Strangely, though, the 2.5:1.5 is spot on - but even the 1:10 isn't and both are higher than usual.

https://www.macartney.com/what-we-o...l-information/conductor-resistance-of-copper/

Well if someone asks you the time it is very rare that someone else will answer "its 27 minutes and 33 and a half seconds past ten in the morning".

Some might say 25 past 10, some might say half past 10, some might it`s between 10 and 11 and some might say it`s thursday morning or even just that it`s thursday. it depends on your need of accuracy in thar particular situation.

Actually, if you look at the published max and min allowed diameter for cable CSA you might be surprised how close some of it is consistently manufactured to with the last few microns of permitted sizes. Makes a bit of a mockery of allowing a manufacturing tolerance so relatively wide open. Of course the manufacturers aim to get away with the least amount of conductor allowable.

Some might say 25 past 10, some might say half past 10, some might it`s between 10 and 11 and some might say it`s thursday morning or even just that it`s thursday. it depends on your need of accuracy in thar particular situation.

Actually, if you look at the published max and min allowed diameter for cable CSA you might be surprised how close some of it is consistently manufactured to with the last few microns of permitted sizes. Makes a bit of a mockery of allowing a manufacturing tolerance so relatively wide open. Of course the manufacturers aim to get away with the least amount of conductor allowable.

Last edited:

They might but not very good if it is a quarter to two on a Tuesday.Well if someone asks you the time it is very rare that someone else will answer "its 27 minutes and 33 and a half seconds past ten in the morning".

Some might say 25 past 10, some might say half past 10, some might it`s between 10 and 11 and some might say it`s thursday morning or even just that it`s thursday. it depends on your need of accuracy in thar particular situation

How do you know which is wrong if you don't know which is correct?

Yes but how correct do you need to be to be considered not wrong?They might but not very good if it is a quarter to two on a Tuesday.

How do you know which is wrong if you don't know which is correct?

"You are telling a lie!" . "Oh no I am not!" . "OK then if it`s not a lie then what is it?". "Well, it`s just a different version of the truth!" . Carla Lane , Bread, old "Electric Head" as we used to refer to him - The father of the Boswell Family - priceless comedy

Depends if you are happy being slap-dash or not.

Do you make a habit of stating something slightly wrong when you know what is correct?

Do you make a habit of stating something slightly wrong when you know what is correct?

Indeed. It's very odd.It seems impossible to find a definitive value of a particular wire to start from. Sites vary significantly in their figures. This one comes up first on my search but as you can see very few of the values on the same site match.

Indeed. As I've said, I'm not so concerned about the absolute differences in figures in different sources (which could be due to all sorts of reasons), but one would expect the ratios of resistance to correspond with the ratio of CSAs to be the same for everything from a single sourceStrangely, though, the 2.5:1.5 is spot on - but even the 1:10 isn't and both are higher than usual.

As you say, the 2.5:1.5 resistance ratio from their figures is 'spot on', but that's not the case with any of the other pairs I've tried - and, at least in most cases, the discrepancies cannot be explained by rounding alone. For example, with the 1:10 (mm²) comparison you mention, the ratio of resistances is appreciably above 10 at both extremes of the possible rounding errors.

As for reasons for absolute differences, are the 'copper conductors' we talk about actually 100% pure copper?

Kind Regards, John

no there is a target and an allowable tolerance too, just to beggar the pure arithmetic of the situationAs for reasons for absolute differences, are the 'copper conductors' we talk about actually 100% pure copper?

Yes, but the number of significant figures in the figures they are quoting indicates the degree of precision ('accuracy') they are working for and, as I've just written, the discrepancy of 'resistance ratios' (in comparison with 'CSA ratios') we are seeing cannot be explained by the rounding alone.Well if someone asks you the time it is very rare that someone else will answer "its 27 minutes and 33 and a half seconds past ten in the morning".

Some might say 25 past 10, some might say half past 10, some might it`s between 10 and 11 and some might say it`s thursday morning or even just that it`s thursday. it depends on your need of accuracy in thar particular situation.

Yes, but as I've also written, even give the existence of manufacturing tolerances (od CSA), no matter how wide, one would expect the quoted resistance figures to relate to the nominal/intended/typical/average/whatever CSA - so, again, should correspond with the raio of those CSA figures.Actually, if you look at the published max and min allowed diameter for cable CSA you might be surprised how close some of it is consistently manufactured to with the last few microns of permitted sizes. Makes a bit of a mockery of allowing a manufacturing tolerance so relatively wide open. Of course the manufacturers aim to get away with the least amount of conductor allowable.

Kind Regards, John

As you presumably realised, my question was almost rhetorical, because there are rarely (if ever) cases of materials which are literally "100%" of anything - I imagine that even 'gold bars'/ingots have allowed tolerations of various 'contaminants.no there is a target and an allowable tolerance too, just to beggar the pure arithmetic of the situation

If different people are making different assumptions about the composition of the 'copper', that could explain small absolute differences - but, again, that should not affect the 'resistance ratios' of conductors with different nominal CSAs.

Kind Regards, John

Let's see if I can work this out using the physics:

The resistivity (rho(Cu)) of pure copper is 1.68x10^-8 Ωm at 20C. The temperature coefficient is 4.04×10^-3/K, so corrected to 25C, rho=1.714x10^-8 Ωm ( a little higher as you would expect. BTW, Ωm is correct, it is not Ω/m)

The resistance of a conductor is given by R=rho*l/A, where l is the length in meters and A is the cross sectional area in m²

2.5mm² is 2.5x10^-6 m²

So the resistance per km at 25C of 2.5mm² copper is R = 1.714x10^-8 * 1000 / 2.5x10^-6 = 6.856Ω, This assumes pure Cu and DC but I would not expect significant reactive effects at 50Hz.

I wonder where the other values come from? Or am I missing something?

The resistivity (rho(Cu)) of pure copper is 1.68x10^-8 Ωm at 20C. The temperature coefficient is 4.04×10^-3/K, so corrected to 25C, rho=1.714x10^-8 Ωm ( a little higher as you would expect. BTW, Ωm is correct, it is not Ω/m)

The resistance of a conductor is given by R=rho*l/A, where l is the length in meters and A is the cross sectional area in m²

2.5mm² is 2.5x10^-6 m²

So the resistance per km at 25C of 2.5mm² copper is R = 1.714x10^-8 * 1000 / 2.5x10^-6 = 6.856Ω, This assumes pure Cu and DC but I would not expect significant reactive effects at 50Hz.

I wonder where the other values come from? Or am I missing something?

Last edited:

Well, (I am being extreme here though) lets say one department or one subcontractor is making all the L conductors, another the N conductors and yet another all the E conductors or even the same department etc but on different days of the week etc etc etc we might get subtle differences. There are many other ways to get subtle differences that might or might not explain some of them. I think most of us have heard the motor manufacturing term "Oh, it`s a Friday Car!".

No two things in the world are exactly the same so it`s a question of how far we need to move away from similarities to start to become significant for our particular application and that includes any theoretical figures we use too.

No two things in the world are exactly the same so it`s a question of how far we need to move away from similarities to start to become significant for our particular application and that includes any theoretical figures we use too.

I'm not arguing - I don't know - but it seems relevant to the discussion:

This site:

www.britannica.com

www.britannica.com

says it is 1.77.

The resistivity (rho(Cu)) of pure copper is 1.68x10^-8 Ωm at 20C.

This site:

Resistance | Ohm’s Law, Voltage, Current

Resistance, in electricity, property of an electric circuit or part of a circuit that transforms electric energy into heat energy in opposing electric current. Resistance involves collisions of the current-carrying charged particles with fixed particles that make up the structure of the conductors.

says it is 1.77.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 6

- Views

- 4K