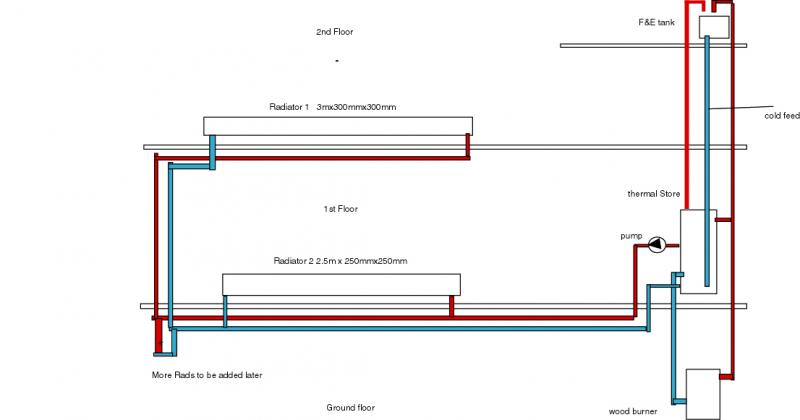

I have a woodburner connected to a gledhill thermal store. I have copied an exsiting system as close as poss.

I have two radiators connected, one 3meters long and the other 2.5 meters long. When the pump switches on it sucks a liitle water from the header tank and when the pump turns off the water is replaced via the vent pipes. This in itself is OK but over a period of time the water in the tank gets quite hot and can overflow. The problem will also happen when the system is cold.

One rad has 22mm pipe right upto the last few feet, the other one has 22mm then 15mm to the last 4 feet

any ideas? Please

Laurel

I have two radiators connected, one 3meters long and the other 2.5 meters long. When the pump switches on it sucks a liitle water from the header tank and when the pump turns off the water is replaced via the vent pipes. This in itself is OK but over a period of time the water in the tank gets quite hot and can overflow. The problem will also happen when the system is cold.

One rad has 22mm pipe right upto the last few feet, the other one has 22mm then 15mm to the last 4 feet

any ideas? Please

Laurel