Hello,

I am hoping for some assistance troubleshooting my UFH system.

Background:

House is about 10yrs old, we are the second owners.

Boiler is a large combination boiler, housed in the garage.

Heating is UFH throughout property, on both floors.

There are two manifolds, one on ground floor, one on first floor.

Downstairs, the manifold feeds circuits as follows:

1. Living room one end

2. Living room other end and hallway

3. Kitchen

4.2nd reception room

5. Orangery - this is turned down, as its not used much in winter and would cost a fortune to heat it to normal room temperature.

The downstairs WC is where the pipes all run under, the manifold being hidden in the wall between WC and kitchen . So it doesn't have a circuit of its own, a couple of loops from kitchen circuit run on one side before they go out through the hall to kitchen.

The living room has the controller in it, and a room stat. Controller is set to 30C so when the program is set to be on, the room temp doesn't shut down the whole system.

Room stat set to 21C.

This stat runs actuators for the two living room circuits.

The kitchen, and reception 2 have room stats respectively.

The orangery is manual valve no stat at the moment, hence the throttling of the manual valve to limit flow. This seems to work fine, as its floor isn't warm like the house, but its certainly not cold tiles as it would be with no heating in the floor.

So to the issues:

1. Since we have lived there, I have found one side of the kitchen floor, and the utility (both are one circuit from the manifold) is cooler, but this winter, even though its not that cold yet, the utility is down right chilly.

When we first moved in, I spoke to the manufacturer and they helped me tweak the settings, as we had some other issues (upstairs the water was set too cool and floors weren't heating rooms, and pumps were all set on 1 in manifolds...). They advicsed setting two or three on the manifold pumps, and upstairs its set to three. Downstairs, I have tried 2 and 3 and it has not remedied the situation. Setting 3 makes something in our walls resonate, unfortunately they fitted the manifold to the studding, not to a brick or block support

2. I noted yesterday, that despite the room stats all having turned off, and rooms all being at temperature, the pump was still running. Since I had left the pump on setting 3 downstairs I was able to hear it. I double checked and all stats required turning up to get a click, so they were all off at idle. This should mean downstairs system should not circulate as I understand.

I set the controller to off, then back to auto, and the pump did not then come back on, unless I bumped any of the thermostats upward, as expected.

So, my main question is ref the kitchen colder floor on one side, in particular on the further end of the loop on that side, and the utility (both one circuit.)

Secondary question ref the pump behaviour.

My manifold is of this type:

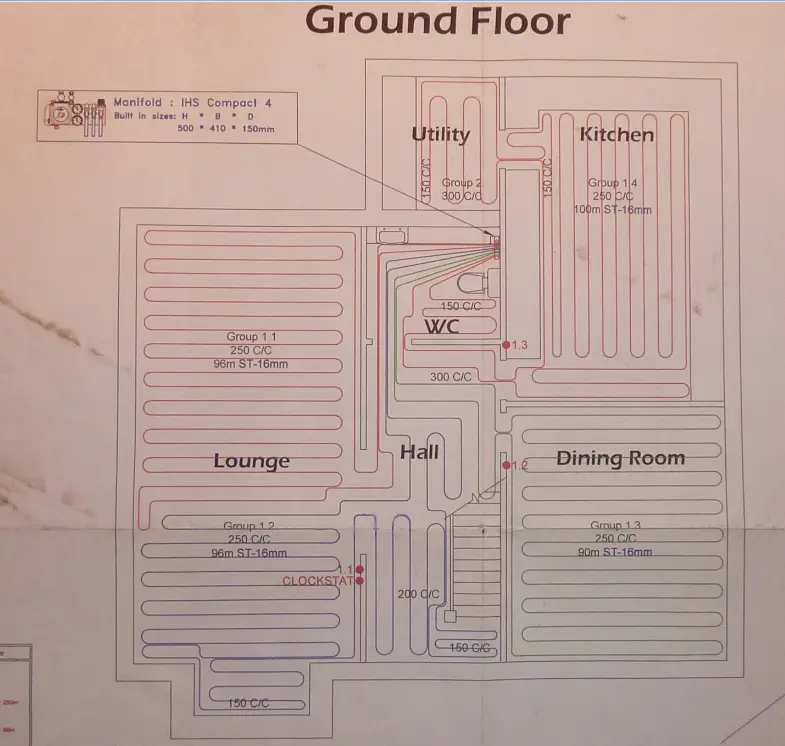

System layout downstairs - orangery not shown, these were plans left from the prev. owners.

As far as I know its correct. The plans from 1st floor didn't quite match the final house - only because they moved a door probably after the initial quoting was done for heating, but walls etc.. all seem to be in the right place.

I am hoping for some assistance troubleshooting my UFH system.

Background:

House is about 10yrs old, we are the second owners.

Boiler is a large combination boiler, housed in the garage.

Heating is UFH throughout property, on both floors.

There are two manifolds, one on ground floor, one on first floor.

Downstairs, the manifold feeds circuits as follows:

1. Living room one end

2. Living room other end and hallway

3. Kitchen

4.2nd reception room

5. Orangery - this is turned down, as its not used much in winter and would cost a fortune to heat it to normal room temperature.

The downstairs WC is where the pipes all run under, the manifold being hidden in the wall between WC and kitchen . So it doesn't have a circuit of its own, a couple of loops from kitchen circuit run on one side before they go out through the hall to kitchen.

The living room has the controller in it, and a room stat. Controller is set to 30C so when the program is set to be on, the room temp doesn't shut down the whole system.

Room stat set to 21C.

This stat runs actuators for the two living room circuits.

The kitchen, and reception 2 have room stats respectively.

The orangery is manual valve no stat at the moment, hence the throttling of the manual valve to limit flow. This seems to work fine, as its floor isn't warm like the house, but its certainly not cold tiles as it would be with no heating in the floor.

So to the issues:

1. Since we have lived there, I have found one side of the kitchen floor, and the utility (both are one circuit from the manifold) is cooler, but this winter, even though its not that cold yet, the utility is down right chilly.

When we first moved in, I spoke to the manufacturer and they helped me tweak the settings, as we had some other issues (upstairs the water was set too cool and floors weren't heating rooms, and pumps were all set on 1 in manifolds...). They advicsed setting two or three on the manifold pumps, and upstairs its set to three. Downstairs, I have tried 2 and 3 and it has not remedied the situation. Setting 3 makes something in our walls resonate, unfortunately they fitted the manifold to the studding, not to a brick or block support

2. I noted yesterday, that despite the room stats all having turned off, and rooms all being at temperature, the pump was still running. Since I had left the pump on setting 3 downstairs I was able to hear it. I double checked and all stats required turning up to get a click, so they were all off at idle. This should mean downstairs system should not circulate as I understand.

I set the controller to off, then back to auto, and the pump did not then come back on, unless I bumped any of the thermostats upward, as expected.

So, my main question is ref the kitchen colder floor on one side, in particular on the further end of the loop on that side, and the utility (both one circuit.)

Secondary question ref the pump behaviour.

My manifold is of this type:

System layout downstairs - orangery not shown, these were plans left from the prev. owners.

As far as I know its correct. The plans from 1st floor didn't quite match the final house - only because they moved a door probably after the initial quoting was done for heating, but walls etc.. all seem to be in the right place.