Hi. I've read through a few related posts and gather this is quite an oldie (and theres quite a few vaillant smarties on here) but I can't afford to replace just right now.

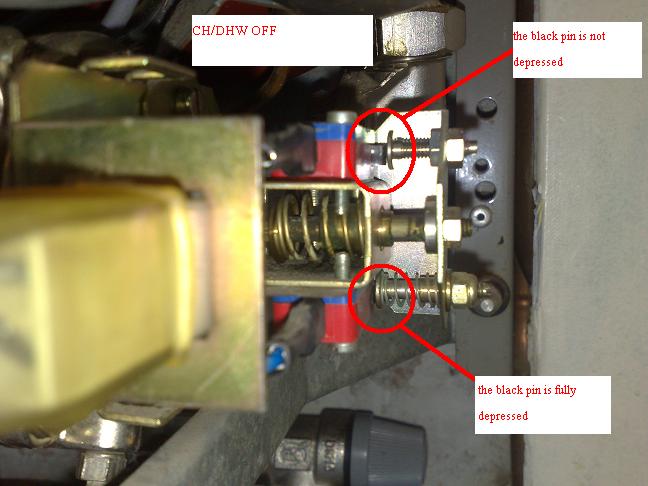

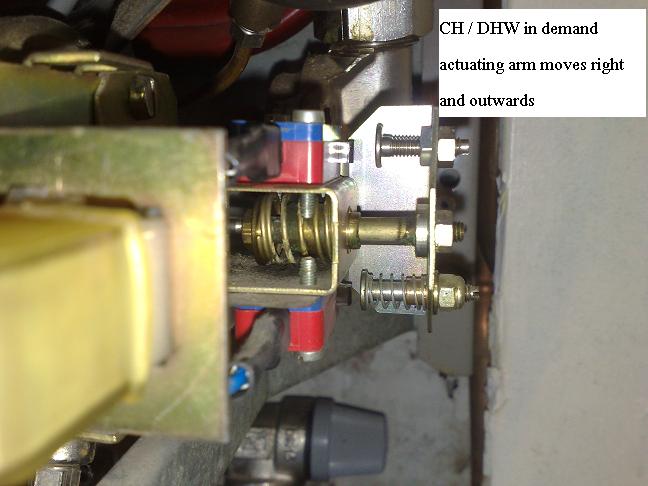

VCW 221 H - PROBLEM : pictures of microswitch + 'stuck' return spring

hot water works fine, demand, click sound, green + amber light on, boiler fires, pump on, hot water.

Central heating:no click, no green+amber, boiler doesn't fire, pump on.

2 years ago BG did a fix price jobbie, similar fault then but they replaced auto air vent, Circulation Pump and Expansion Vessel CH - seemed to sort it out.

last year had problem with pilot light going out intermittently so I replaced thermocouple.

both CH and DHW working fine through winter 07 but CH off since, past few weeks tried to get CH and it wont work.

manually poking microswitch behind servo triggers green then amber light and fires boiler but only for a few minutes.

desperate to see if it's a diy fix before winter kicks in, got a quote from BG 210 pounds

all help appreciated, got an electric heater on standy as theres a kid in the house - will bite the bullet and pay if it can't be fixed

other info:

-room thermostat clicks on/off at around 22c

-there appears to be some minor calcification on some pipes below servo.

-also water pressue unstable, increases intermittently from 1 bar up to 3

-thermostat on boiler is not working so can't get any temps if that's an

issue

VCW 221 H - PROBLEM : pictures of microswitch + 'stuck' return spring

hot water works fine, demand, click sound, green + amber light on, boiler fires, pump on, hot water.

Central heating:no click, no green+amber, boiler doesn't fire, pump on.

2 years ago BG did a fix price jobbie, similar fault then but they replaced auto air vent, Circulation Pump and Expansion Vessel CH - seemed to sort it out.

last year had problem with pilot light going out intermittently so I replaced thermocouple.

both CH and DHW working fine through winter 07 but CH off since, past few weeks tried to get CH and it wont work.

manually poking microswitch behind servo triggers green then amber light and fires boiler but only for a few minutes.

desperate to see if it's a diy fix before winter kicks in, got a quote from BG 210 pounds

all help appreciated, got an electric heater on standy as theres a kid in the house - will bite the bullet and pay if it can't be fixed

other info:

-room thermostat clicks on/off at around 22c

-there appears to be some minor calcification on some pipes below servo.

-also water pressue unstable, increases intermittently from 1 bar up to 3

-thermostat on boiler is not working so can't get any temps if that's an

issue