should point out that your pump should be on max and if anything is possibly undersized. Your particular boiler has a coil type heat exchanger with a high resistance and as such requires a decent size pumpto prevent any issues.

Hi Micky,

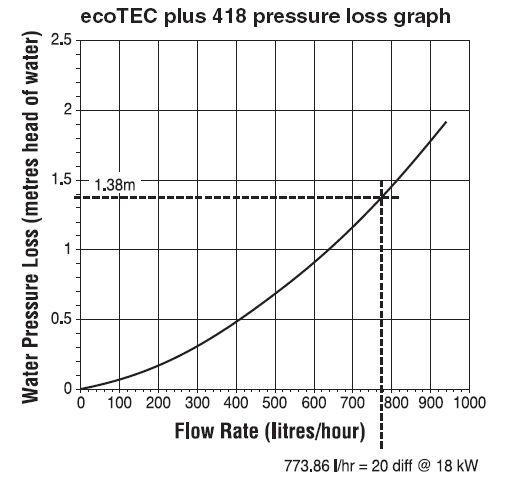

Looking through the Vaillant manual, the ecoTEC 418 requires a min flow rate of 12.9 litres per minute (or 0.77 m3/h). The water pressure loss (metres head of water) is 1.38m at 773.86 litres per hour (0.77 m3/h) (see pic).

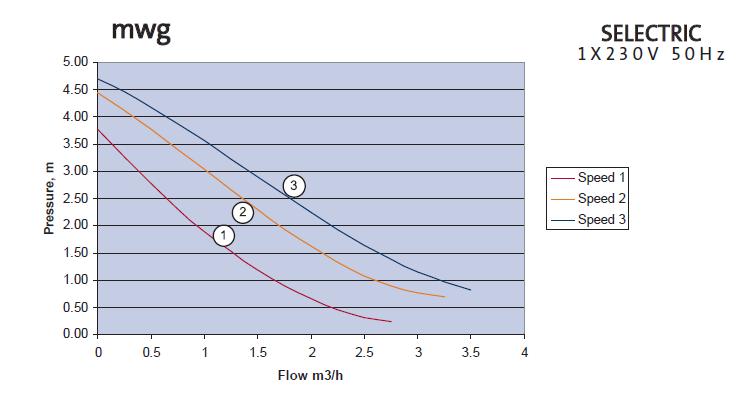

I have around 4m head between the F&E and boiler, the pump sits roughly in the middle @ 2m. Looking at the Grundfos specs (see pic), if I use the lowest figure (2m), the pump delivers the following flow rates:

Speed I = 0.9 m3/h

Speed II = 1.6 m3/h

Speed III = 2.1 m3/h

As the boiler requires 0.77 m3/h, Speed I looks to be a bit of a push but II & III both look to give acceptable flow!?

If I'm getting this all wrong (very possible lol), I'd really appreciate if anyone could point out my errors!!

P.s. I realise that I've not accounted for the resistance in the 28mm copper pipe between pump and boiler... is there a way to calculate that?