Curious about how those on here handle testing RCD's when doing EICR's or MWC's?

If you have several circuits protected by an RCD as is often the case, do you test the RCD on each circuit it protects or just once for each RCD what is ideally done with no loads at the distribution board.

In other words, do you simply test that the RCD it's self functions correctly or do you also test it functions under earth fault conditions on every circuit (or even socket outlet) it protects.

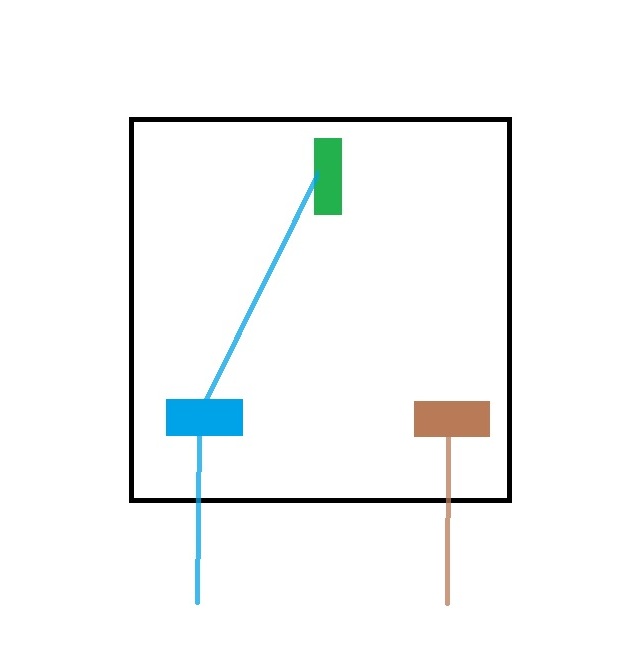

I.e. You have a very odd socket that is not earthed, but has the neutral and earth terminals joined together. On first glance, that socket may appear to be ok and pass it's Zs test.

Assuming you're unaware of the fault and thus have not done any of the following;

Regards: Elliott.

If you have several circuits protected by an RCD as is often the case, do you test the RCD on each circuit it protects or just once for each RCD what is ideally done with no loads at the distribution board.

In other words, do you simply test that the RCD it's self functions correctly or do you also test it functions under earth fault conditions on every circuit (or even socket outlet) it protects.

I.e. You have a very odd socket that is not earthed, but has the neutral and earth terminals joined together. On first glance, that socket may appear to be ok and pass it's Zs test.

Assuming you're unaware of the fault and thus have not done any of the following;

- A R1 + R2 test at the DB with the joint/link at the defective socket, what would hopefully show ∞Ω

- A N-E IR test initiated at the defective socket what would show at or very close to 0Ω

Regards: Elliott.