We're looking to remove a load bearing wall, which is supporting one wall of a gabel, the floor above, ceiling above and roof above. I've sent our structural engineers calcs to my dad and we're both a bit concerned.

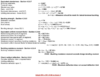

The above image shows the wall (and chimney to be removed). The wall is supporting the joists from Room 2, and the section of Room 1 to the right of the existing steels (supporting another gable).

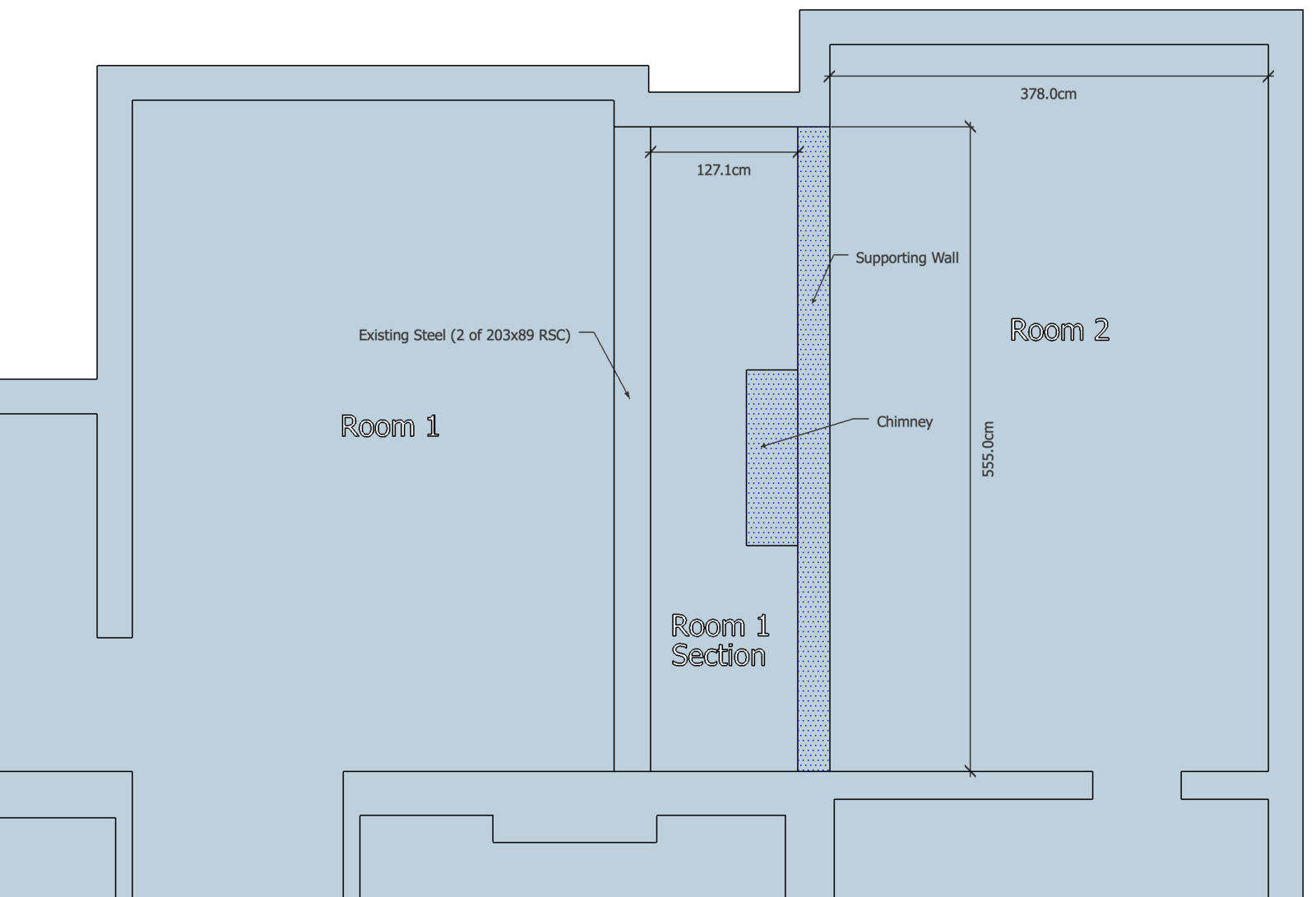

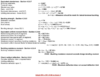

The values the engineer has used for his calcs is here:

And he has come up with requiring a 203x203 UC46.

Some of my/our worries are:

- The floor loads only take in to account the floor for Room 2, and not the section of Room 1 who's joists are supported between the existing steels and the wall to be removed.

- The wall dead load is for a 2m high wall. The wall is at least 2.5m tall above the steel.

- There are no calculations for the chimney. He has stated that gallows brackets are fine.

- The roof load is for just the width of the room, and doesn't take in to account the steep pitch of the roof.

- Ceilings and stored items in the loft havn't been taken in to account.

- My old man thinks the weight required for the roof is too small.

- He's calculated the span as 5.2m, when it's clearly more than that.

Now I'm no structural engineer, but some of the above points seem quite worrying, and I wouldn't imagine they're included in the 1.4 and 1.6 safety factors that are used in the calculations.

Is anyone able to put my mind at ease and let me know what steels they used for their houses? Or if any structural engineers know that the specified steel is roughle correct?

Obviously I'll follow up with the engineer, but the fact that he's clearly missed some stuff is pretty worrying.

Any help is greatly appreciated.

Edit - more calcs:

The above image shows the wall (and chimney to be removed). The wall is supporting the joists from Room 2, and the section of Room 1 to the right of the existing steels (supporting another gable).

The values the engineer has used for his calcs is here:

And he has come up with requiring a 203x203 UC46.

Some of my/our worries are:

- The floor loads only take in to account the floor for Room 2, and not the section of Room 1 who's joists are supported between the existing steels and the wall to be removed.

- The wall dead load is for a 2m high wall. The wall is at least 2.5m tall above the steel.

- There are no calculations for the chimney. He has stated that gallows brackets are fine.

- The roof load is for just the width of the room, and doesn't take in to account the steep pitch of the roof.

- Ceilings and stored items in the loft havn't been taken in to account.

- My old man thinks the weight required for the roof is too small.

- He's calculated the span as 5.2m, when it's clearly more than that.

Now I'm no structural engineer, but some of the above points seem quite worrying, and I wouldn't imagine they're included in the 1.4 and 1.6 safety factors that are used in the calculations.

Is anyone able to put my mind at ease and let me know what steels they used for their houses? Or if any structural engineers know that the specified steel is roughle correct?

Obviously I'll follow up with the engineer, but the fact that he's clearly missed some stuff is pretty worrying.

Any help is greatly appreciated.

Edit - more calcs:

Last edited: