Never used a beam with a plate less than 10mm.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

steel beam bowing

- Thread starter showtime247

- Start date

will speak with structural tomorrow beam is UB254x102x22 with an 8mm welded bottom plate looks like the plate that is rotating only a beam has no flex really dont want too add a mid point post if i can help it. just measure ed of beam and looks like builders have installed correct beam.

254 x 102 x 22 UB - there's your issue! Massively undersized for a 7.5m span...

The loads from a flat roof are generally less that would be if pitched, so the beam section may be OK.

It may be the plate welds, as 8mm should still be good for those two course of blocks

The blockwork is crap though. No bricklayer laid those.

It may be the plate welds, as 8mm should still be good for those two course of blocks

The blockwork is crap though. No bricklayer laid those.

- Joined

- 19 Apr 2022

- Messages

- 27

- Reaction score

- 0

- Country

it needs to take 4 course of blocks wood no the 2

It will always flex to some degree but if designed to its serviceability limit state the deflection should be acceptable, designing to its ultimate limit state will hopefully prevent beam failure.You don't need to prop beams, as they do not rely on the masonry immediately above it like common steel lintels do.

A steel beam is designed to limit state, ie to support its design load without flexing.

Correct.The blockwork is crap though. No bricklayer laid those.

Probably the most vulnerable location the bricklayer has ever worked over and decided to lay blocks quarter nick. Nucking futz.

The beam should be propped.

Blocks should be half bonded.

Wouldn't surprise me if there was meant to be brickwork 'arching' above that beam externally.

Crap builders.

Ask for a copy of his calcs and post them up. As for the 20mm its all a question of aesthetics, Deflection in a beam should generally be restricted to 1/360 but as the beam seems to be ok at its current loading it looks like its down to the deflection of the plate and whether 20mm is considered visually acceptable to the end user i.e. you.will speak with structural tomorrow beam is UB254x102x22 with an 8mm welded bottom plate looks like the plate that is rotating only a beam has no flex really dont want too add a mid point post if i can help it. just measure ed of beam and looks like builders have installed correct beam.

Last edited:

A plate should not deflect when just part loaded with one course and a part course of blocks!the beam seems to be ok at its current loading it looks like its down to the deflection of the plate and whether 20mm is considered visually acceptable to the end user i.e. you.

It should (will) have maximum deflection when the maximum load is applied, so in this case it will only get worse.

Never ever use a 254x102 UB as a lintel above a doorway. They are useless unless restrained as they are too slender and will buckle long before they reach their full bending resistance.

A 254x102 simply isn't sufficient for the span (my quick check indicates a 254x146x43 as an absolute minimum), but the other issue is torsion (which will mean a 254x146x43 won't work either). The load of the outer leaf on the plate will put torsion into the beam that 254x102s simply can't handle. I guarantee that check hasn't been carried out.

I'd be putting in a large rectangular hollow section (which rarely fail in torsion) and limiting deflection to around 13mm (otherwise there are potential issues with any doors under it).

The plate supporting the outer leaf also looks undersized - I usually either use a 10mm plate or get stiffeners welded in at 600mm centres that protrude the full width of the cavity.

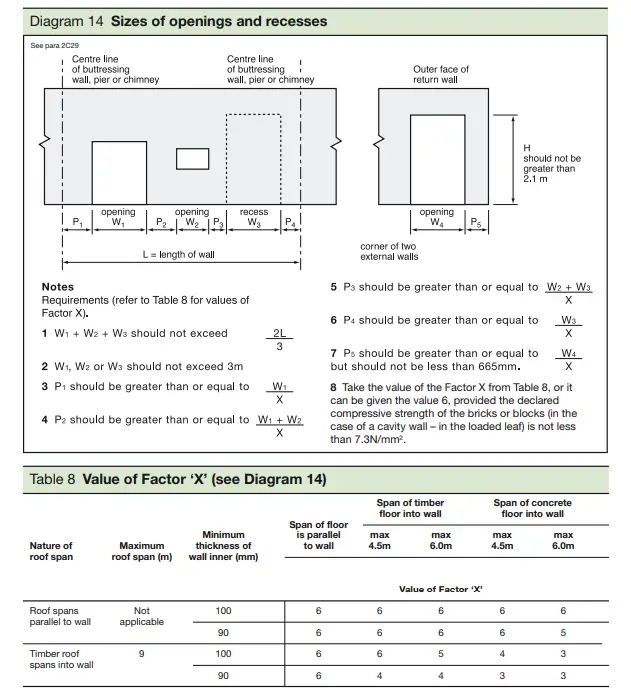

It's also not possible to justify the 900mm returns in relation to Approved Document A, so for spans of that sort of size I always specify a wind post either end of the opening (see below)

A 254x102 simply isn't sufficient for the span (my quick check indicates a 254x146x43 as an absolute minimum), but the other issue is torsion (which will mean a 254x146x43 won't work either). The load of the outer leaf on the plate will put torsion into the beam that 254x102s simply can't handle. I guarantee that check hasn't been carried out.

I'd be putting in a large rectangular hollow section (which rarely fail in torsion) and limiting deflection to around 13mm (otherwise there are potential issues with any doors under it).

The plate supporting the outer leaf also looks undersized - I usually either use a 10mm plate or get stiffeners welded in at 600mm centres that protrude the full width of the cavity.

It's also not possible to justify the 900mm returns in relation to Approved Document A, so for spans of that sort of size I always specify a wind post either end of the opening (see below)

Last edited:

Well assuming the load on the plate is acting 0.125m away from the edge of the beam and the load on the plates is 100kg/ metre run then I calculate the deflection as 0.007mm. based on deflection = W.L.L.L/3EI but I could be wrongA plate should not deflect when just part loaded with one course and a part course of blocks!

It should (will) have maximum deflection when the maximum load is applied, so in this case it will only get worse.

Not withstanding the buckling note, thats interesting as I did a quick check using the Blue Book and depending what roof span and loads were taken there seemed to be a possibility that it could suffice. As a matter of interest what loading did you take for the span.Never ever use a 254x102 UB as a lintel above a doorway. They are useless unless restrained as they are too slender and will buckle long before they reach their full bending resistance.

A 254x102 simply isn't sufficient for the span (my quick check indicates a 254x146x43 as an absolute minimum), but the other issue is torsion (which will mean a 254x146x43 won't work either). The load of the outer leaf on the plate will put torsion into the beam that 254x102s simply can't handle. I guarantee that check hasn't been carried out.

Would buckling not be restricted by the roof joists to some extent?

It's a flat roof. Vertical loads.Would buckling not be restricted by the roof joists to some extent?

Yes the joists would tie into the beam and stop sideways/ buckling movement?It's a flat roof. Vertical loads.

No, three reasons (off the top of my head).Yes the joists would tie into the beam and stop sideways/ buckling movement?

1: It's risky to use joists to prevent buckling as it relies on them being cut perfectly and tight to the beam.

2: Usual for the joists to bear above the beam when used as a lintel so don't provide any restraint.

3: The joists would only be coming in from the one side so the risk would be that the top flange would buckle outwards.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local