I need a replacement pump head for a Grundfos 15/60-130 3 speed central heating system. Can I assume that the various manufacturers replacements all conform to the same 4 Allen screw fixing dimensions of about 80mm spacing? I am confused by the various letters applied to the part names that have started to appear like CESA 03, CESA 02, AOKR. Are these some form of energy indication or maybe the connection details. I just want 3 terminals to wire to.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

15-60/130 pump details

- Thread starter DMR1

- Start date

I wouldn't dream of replacing the pump head with a non Grundfos one, if this is what you are suggesting?. I don't think there is a huge difference in cost between a new pump and a replacement head. You could consider a DAB Evosta or one like my own, a Wilo Yonos PIco which gives the very best of all mode settings.

No they are not all the same, either another Grundfoss or a multi head kit

I am not particularly looking for a non-Grundfos one, just trying to make sense of the market as to what is available. Lots of pump heads but no dimensions and no connection details. The existing pump just seemed to stop trying at the end of the winter and I suspected a blockage. Turns out the pumps capacitor is down to 0.95uF and the speed switch seems to have no effect. I have flushed the system with clean water to no effect. Hot water is OK on 1/2" pipework but heating is microbore. Finally I cannot shift either gate valve nut on the pump which was installed by a grumpy fellow, initially leaving a leak on said nuts which he then graunched up tight, but the motor came off readily. Hence my questions. This pump replaced a Grundfos 18/60-130 (no longer made) in 2007 and has always had to be on speed 3 so effectively I am looking at (maybe) a 2 speed Grundos with more oomph.

When I took mine apart with the same intention to swap the head this is what I found. So I also had to do battle with the gate valves, but in the end was not so bad. Luckily I had bought a complete new pump from a well known auction site (it was cheaper than buying the head only).

Hope yours is looking better than this!

Hope yours is looking better than this!

Well, I got it wrong. I bought a pump head labelled UPSO15-60 CESA02 with higher wattage rating from a boiler parts company having just asked about the 4-hole spacing and told it would fit, which it did. All such pumps are sold showing just a front view of the pump and non of them show the impeller end. I didn't ask for a view of the impeller. The thing turned up with a plastic fitment on the impeller end which I didn't need and was not in the picture. On removing that, it was apparent that the impeller was wider-vaned (same overall length) and smaller diameter. It looked like it might do the job and was perhaps just an improved design with its "Low Energy" label. My old pump would fit into the new plastic (unwanted) housing, despite having a much bigger impeller diameter so I considered I was OK. So, having applied a system flush for good measure, I fitted it and switched on at speed III. the result is very weak flow, even via the 3/4" and 1/2" hot-water loop, let alone the micro-bore radiator system. The boiler is short-cycling.

So Grundfos CESA02 and CESA03 are specific application pumps and not direct replacements for standard Grundfos ones at all. The unwanted plastic end is a totally a different design to the cast iron original. The AOKR version seems to be an air pump!

Thank you Gasguru for a meaningful reply, but I ask a slight variation now. The original pump (back in 1984 to 2006) was a Grundfos UPS 18-60/130 which no longer exists. After looking better, the (2006) replacement does have UPS in the front of its title, but had to be run on speed III and was noisier than the original 18-60 on speed II. I found one comment from the building trade that a 15-60/130 pump is suitable for a 1-3 bedroomed house. I have 4 bedrooms and 15 radiators on micro-bore. Should I be looking at a UPS 20-60/130 complete assembly replacement and someone man/tooled enough to shift the gate valve nuts?

I still don't know what CESA stands for and can anyone define UP and/or UPS because Google totally fails.

So Grundfos CESA02 and CESA03 are specific application pumps and not direct replacements for standard Grundfos ones at all. The unwanted plastic end is a totally a different design to the cast iron original. The AOKR version seems to be an air pump!

Thank you Gasguru for a meaningful reply, but I ask a slight variation now. The original pump (back in 1984 to 2006) was a Grundfos UPS 18-60/130 which no longer exists. After looking better, the (2006) replacement does have UPS in the front of its title, but had to be run on speed III and was noisier than the original 18-60 on speed II. I found one comment from the building trade that a 15-60/130 pump is suitable for a 1-3 bedroomed house. I have 4 bedrooms and 15 radiators on micro-bore. Should I be looking at a UPS 20-60/130 complete assembly replacement and someone man/tooled enough to shift the gate valve nuts?

I still don't know what CESA stands for and can anyone define UP and/or UPS because Google totally fails.

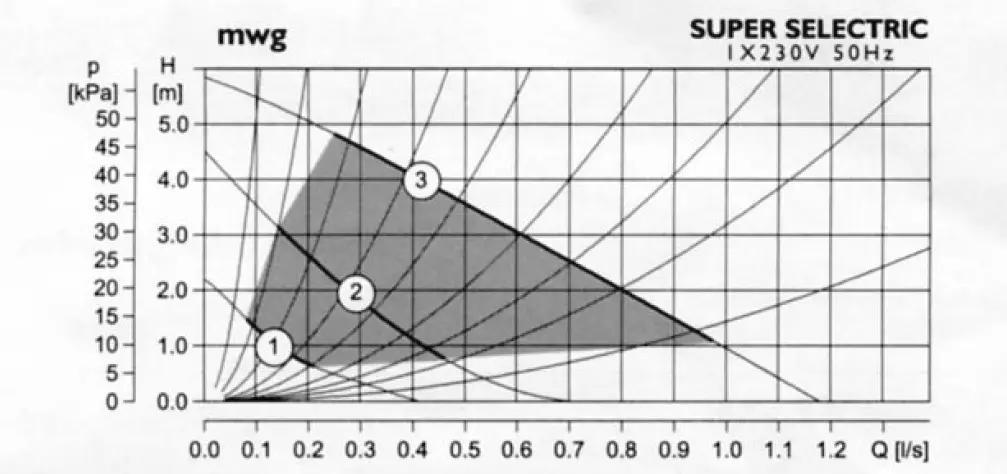

This will do the job for you, a UPS3 15-50/65, a 6.5M pump. Your original pump may have been a Grundfos Selectric or super selectric.

Re gate valve nuts, you can cut across the nut with a junior hacksaw and it will "fall"off then, remove the pump, you should be able to buy two replacement (slotted) nuts like shown in the attachment and fit them without disturbing the actual isol valves and having to drain down the whole system. You can split the nut(s) in a few minutes if you have room to cut across one of the slots.

Re replacement pump head, its very important that the impeller eye fits into the casing bore with only a few "thou" clearance as otherwise the pump pressure will recirculate too much water back to the suction side, more so if the replacement impeller is too short and doesn't actually enter the bore at all.

Re gate valve nuts, you can cut across the nut with a junior hacksaw and it will "fall"off then, remove the pump, you should be able to buy two replacement (slotted) nuts like shown in the attachment and fit them without disturbing the actual isol valves and having to drain down the whole system. You can split the nut(s) in a few minutes if you have room to cut across one of the slots.

Re replacement pump head, its very important that the impeller eye fits into the casing bore with only a few "thou" clearance as otherwise the pump pressure will recirculate too much water back to the suction side, more so if the replacement impeller is too short and doesn't actually enter the bore at all.

Attachments

Last edited:

Thank you Johntheo5. Sound advice about the gate valves that I had not considered. Original pump was a Grundfos Super Selectric and I should have said that along with the UPS in its description.

As explained at the start, I checked the dimensions of that pump/impeller against the one it replaced. Distance out from the casing was identical on a vernier caliper and it's eye was the same diameter so it fitted the inlet side just the same. Only the blades themselves were different/smaller diameter/wider. It does seem odd that the thing is so demonstrably ineffective. No better than the one it replaced in its weak (capacitor) state.

I have to say I am not too enthusiastic about your suggestion of UPS3 15-50/65 which seems an unnecessarily complex item, as do your earlier suggestions. I still feel I should get a straight forward bigger 2-3 speed variety. I don't see the point of introducing electronics into hot pumps, being an ex-engineer in the field.

As explained at the start, I checked the dimensions of that pump/impeller against the one it replaced. Distance out from the casing was identical on a vernier caliper and it's eye was the same diameter so it fitted the inlet side just the same. Only the blades themselves were different/smaller diameter/wider. It does seem odd that the thing is so demonstrably ineffective. No better than the one it replaced in its weak (capacitor) state.

I have to say I am not too enthusiastic about your suggestion of UPS3 15-50/65 which seems an unnecessarily complex item, as do your earlier suggestions. I still feel I should get a straight forward bigger 2-3 speed variety. I don't see the point of introducing electronics into hot pumps, being an ex-engineer in the field.

You have some serious sludge in there, you need to sort that

Did you try just replacing the capacitor on your super selectric?Thank you Johntheo5. Sound advice about the gate valves that I had not considered. Original pump was a Grundfos Super Selectric and I should have said that along with the UPS in its description.

As explained at the start, I checked the dimensions of that pump/impeller against the one it replaced. Distance out from the casing was identical on a vernier caliper and it's eye was the same diameter so it fitted the inlet side just the same. Only the blades themselves were different/smaller diameter/wider. It does seem odd that the thing is so demonstrably ineffective. No better than the one it replaced in its weak (capacitor) state.

I have to say I am not too enthusiastic about your suggestion of UPS3 15-50/65 which seems an unnecessarily complex item, as do your earlier suggestions. I still feel I should get a straight forward bigger 2-3 speed variety. I don't see the point of introducing electronics into hot pumps, being an ex-engineer in the field.

Re new A rated pumps, they are the only show in town now and I wouldn't be that worried about their longevity, they certainly won't last as long as the older types but I know of several (DAB) in service for > 8 years with no problems, I have a 6M Wilo Yonos Pico for ~ 3 years that I bought new on screwfix for around 100 quid or so, if I knock 5 years or so out of it I'll be quite happy. You can buy Trident or Janesboro? B or C rated traditional like pumps on Amazon for ~ £50/£80 but users reviews vary widely, personally, I wouldn't touch them. Whatever pump you do go for ensure to have a look at the pump curves as a 6.4M Grundfos UPS3 is far more powerful than say a 4- 7M DAB Evosta2.

You have 15 rads say 22.5kW total @ 1.5kW/rad, if you allow for a rad dT of say 12C then flowrate (probably max) required is 26.9LPM or 1.6M3/hr, the UPS3 will give this flowrate at a head of over 5M but the DAB will only give this at 3.8M both on constant curve ("fixed speed") 3.

I am also a ex engineer with ~ 40 years experience of all forms of pumping systems and I don't think you would regret going for a A rated pump, whatever your preferred manufacturer.

You have some serious sludge in there, you need to sort that

That was charlie275's pump.

Surprised that the muck possibility has not reared its head before, so I need to clear that up. Fact is there was some rust evident on the sides of the header tank when I first started looking at this and rust in all the circulating water, which would have contained some Fernox, but it would have been there since 2006ish. All cleared out but not considered relevant to flow rates. Before any pump changes, I added 2 pots of cleaner stuff I happened to get from Wicks and got that hot round everywhere by shutting most of the system off in stages. That was drained out. Then a refill with just water, a hot flush as before, and another drain. That was all before I found the capacitor (which happens to be buried on the unseen side in the airing cupboard), and I have an in-circuit capacitance meter from work days. Just for good measure the whole system was drained again to change the pump and be sure I got all the cleaner out. The pump that came out was not anything like or even approaching charlie275's one. Since then I have drained again to change the CH control valve, effectively on a whim, knowing already that the replacement pump was not proving effective on HW circulation. Just to give you a laugh; I was fooled at one stage because a demand from me for CH was not happening and I though I had a control valve or timer fault. Both upstairs and downstairs thermostats had opened on a warm day.

A few fill-in facts, and just to be clear; all controls, pump and valves are in the airing cupboard upstairs. Only the boiler is downstairs with the header tank in the loft:

1. Since the radiator circulation split-off is under the upstairs landing, draining the system involves draining all the downstairs rads in turn which have their own drain outlets. Long job on carpets but all done.

2. No one. not even the likes of RS and Farnell have correct spec capacitors in stock. That is what I considered first. Variously due in July, August, September. There are some far less expensive ones but the spec is inferior and I have no desire for controller output faults or blown fuses a little later. Has there been a run on faulty capacitors?

3. Water comes out at the boiler drain (system low point) at a fair rate considering the hose involved. It does that with or without the CH & HW valves open or shut, thus effectively proving both legs to and from the boiler in the 3/4"pipework.

If a blockage remains, since the fault is common to both circuits, then it would have to be in that 3/4" pipe run. but I suppose there could be a partial airlock. Not a very serious comment.

4. I can do the same sort of thing with each downstairs rad. Close one end off and prove a good drain cock flow from both legs to each rad.

4. With CH on (HW off) and all rad valves open, the upstairs rads get hot eventually. The downstairs ones (longer pipe runs) are just aired and don't get hot with the upstairs ones closed. This is just about how things were at winters end before the pump change.

So., Kidgreen61, fair comment, but no sludge, serious or otherwise. I have done my homework. perhaps I should try and get at the capacitor in the replacement pump. Too many other things on and this is not high priority at this time of year. However I'm not leaving it until it is.

Hope all that clears the sludge/blockage possibility. This is getting longer.

A few fill-in facts, and just to be clear; all controls, pump and valves are in the airing cupboard upstairs. Only the boiler is downstairs with the header tank in the loft:

1. Since the radiator circulation split-off is under the upstairs landing, draining the system involves draining all the downstairs rads in turn which have their own drain outlets. Long job on carpets but all done.

2. No one. not even the likes of RS and Farnell have correct spec capacitors in stock. That is what I considered first. Variously due in July, August, September. There are some far less expensive ones but the spec is inferior and I have no desire for controller output faults or blown fuses a little later. Has there been a run on faulty capacitors?

3. Water comes out at the boiler drain (system low point) at a fair rate considering the hose involved. It does that with or without the CH & HW valves open or shut, thus effectively proving both legs to and from the boiler in the 3/4"pipework.

If a blockage remains, since the fault is common to both circuits, then it would have to be in that 3/4" pipe run. but I suppose there could be a partial airlock. Not a very serious comment.

4. I can do the same sort of thing with each downstairs rad. Close one end off and prove a good drain cock flow from both legs to each rad.

4. With CH on (HW off) and all rad valves open, the upstairs rads get hot eventually. The downstairs ones (longer pipe runs) are just aired and don't get hot with the upstairs ones closed. This is just about how things were at winters end before the pump change.

So., Kidgreen61, fair comment, but no sludge, serious or otherwise. I have done my homework. perhaps I should try and get at the capacitor in the replacement pump. Too many other things on and this is not high priority at this time of year. However I'm not leaving it until it is.

Hope all that clears the sludge/blockage possibility. This is getting longer.

Last edited:

Normally the capacitor is in the pump wiring terminal box, if I recall correctly my old 65W Salmson circ pump had a 2uf capacitor, the super selectric had several power versions ranging from around 65W to 105W so the capacitor could have been anything up to 5uf, if you can identify the correct one for your pump then even a externally mounted one (anywhere) as long as its electrically safe will do the job and should be relatively easy to source and may solve your problems as 0.95uf is possibly not able to get the motor/pump up to even its minimum speed so very low pump head and circulation flow. As you say, the capacitor in the spare pump may suffice and doesn't matter if its overrated assuming that the capacitor doesn't act as a run capacitor as well, if it does , its important to get the specified rated one.

My daughter has a 16 year old 95W Super Selectric that I installed and the original capacitor is in this one, pump/circ rate is perfect whatever the state the capacitor is and pump is running on speed setting 2.,

My daughter has a 16 year old 95W Super Selectric that I installed and the original capacitor is in this one, pump/circ rate is perfect whatever the state the capacitor is and pump is running on speed setting 2.,

Last edited:

Your system is "VCP" where from the boiler, you have the vent then cold feed then pump where the vent and cold feed should be no more than 150mm apart to prevent vent pump over and air ingress, however, if the pump head is too great you can still get this pump over/air ingress especially when the pump starts/stops, you could fill a small book with people who get this problem even on the seemingly simple task of installing a new pump. It is vital that the new pump should very closely match the old pump settings, anyone reading this should jot down the model/speed settings of their old pump and choose one that can give the same performance before change out.

The pump that I installed (16 years ago) was manufactured 18 years ago, its actually a (5M) Selectric, you can see the year/week of manufacture on the label, PC:0414. You might post a photo of your one and we can try and establish its pump curve to match a new pump to it, IF this is required.

You can also see that it has a 2uF capacitor?.

Edit: Found curves for a UPS15-60 95W Super Selectric so looks like a head of 3.8M at a flowrate of 1.6M3/hr. (0.44 l/s)

The pump that I installed (16 years ago) was manufactured 18 years ago, its actually a (5M) Selectric, you can see the year/week of manufacture on the label, PC:0414. You might post a photo of your one and we can try and establish its pump curve to match a new pump to it, IF this is required.

You can also see that it has a 2uF capacitor?.

Edit: Found curves for a UPS15-60 95W Super Selectric so looks like a head of 3.8M at a flowrate of 1.6M3/hr. (0.44 l/s)

Attachments

Last edited:

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 7

- Views

- 4K

- Replies

- 39

- Views

- 10K