I suggested no such thing.Are we saying that there is no need to glue the conduit joins?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

20mm Plastic Trunking

- Thread starter polomints

- Start date

- Joined

- 11 Jan 2004

- Messages

- 46,212

- Reaction score

- 3,652

- Country

I think there is merit in using conduit for mechanical protection.

Over the years, I have seen a few cables chopped by hedgetrimmers etc...

Over the years, I have seen a few cables chopped by hedgetrimmers etc...

My hedge trimmer could probably get through plastic conduit without much difficulty (it has certainly been known to get through a garden hoseI think there is merit in using conduit for mechanical protection. Over the years, I have seen a few cables chopped by hedgetrimmers etc...

Kind Regards, John

- Joined

- 11 Jan 2004

- Messages

- 46,212

- Reaction score

- 3,652

- Country

But with something rigid like conduit ( as compared to a floppy hose [ooh err missus!]), the conduit may prevent damage to the cable by alerting the unalert user of said chopping device to the fact that it is no longer slicing through the shrubbery.

Maybe - but the design of most hedge cutter blades is such that they would probably be fairly hard-pressed to damage a cable which was clipped firmly (at frequent intervals) direct to a wall, whereas the more protruding conduit (and contained cable) would probably be a more susceptible target! ... so maybe swings and roundabouts to some extent.But with something rigid like conduit ( as compared to a floppy hose [ooh err missus!]), the conduit may prevent damage to the cable by alerting the unalert user of said chopping device to the fact that it is no longer slicing through the shrubbery.

Kind Regards, John

That couldn't possibly be prevented by PVC conduit. Steel conduit would be required to achieve that end (or for the end user to exercise a bit more care).I think there is merit in using conduit for mechanical protection.

Over the years, I have seen a few cables chopped by hedgetrimmers etc...

Oops sorry, i picked up the 16th, i will look later, its too do with all Non metallic conduit and fittings must be a certain bs number, which i quess will not the same as plumbing pipeCould you translate that into 17th ed-speak?

Kind Regards, John

Fair enough - I look forward to hearing what 17th ed refulation we are talking about.Oops sorry, i picked up the 16th, i will look later, its too do with all Non metallic conduit and fittings must be a certain bs number, which i quess will not the same as plumbing pipe

On the face of it, when plastic conduit is being used 'unnecessarily' (i.e. to enclose cable that would be OK and compliant without it), it's hard to see why the regs would impose any 'requirements' in relation to that conduit.

Kind Regards, John

- Joined

- 27 Apr 2008

- Messages

- 10,288

- Reaction score

- 1,201

- Country

There is a house near me that has had a long run of black pvc conduit on the outside walls for years with no apparent problem.

As a suggestion for drainage, how about using an inverted T junction with a short length of pipe in. At least no drainage holes will get blocked up then

As a suggestion for drainage, how about using an inverted T junction with a short length of pipe in. At least no drainage holes will get blocked up then

Fit a tap every few metres, and open it up when it rains. Simples!

- Joined

- 28 Jul 2014

- Messages

- 1,969

- Reaction score

- 566

- Country

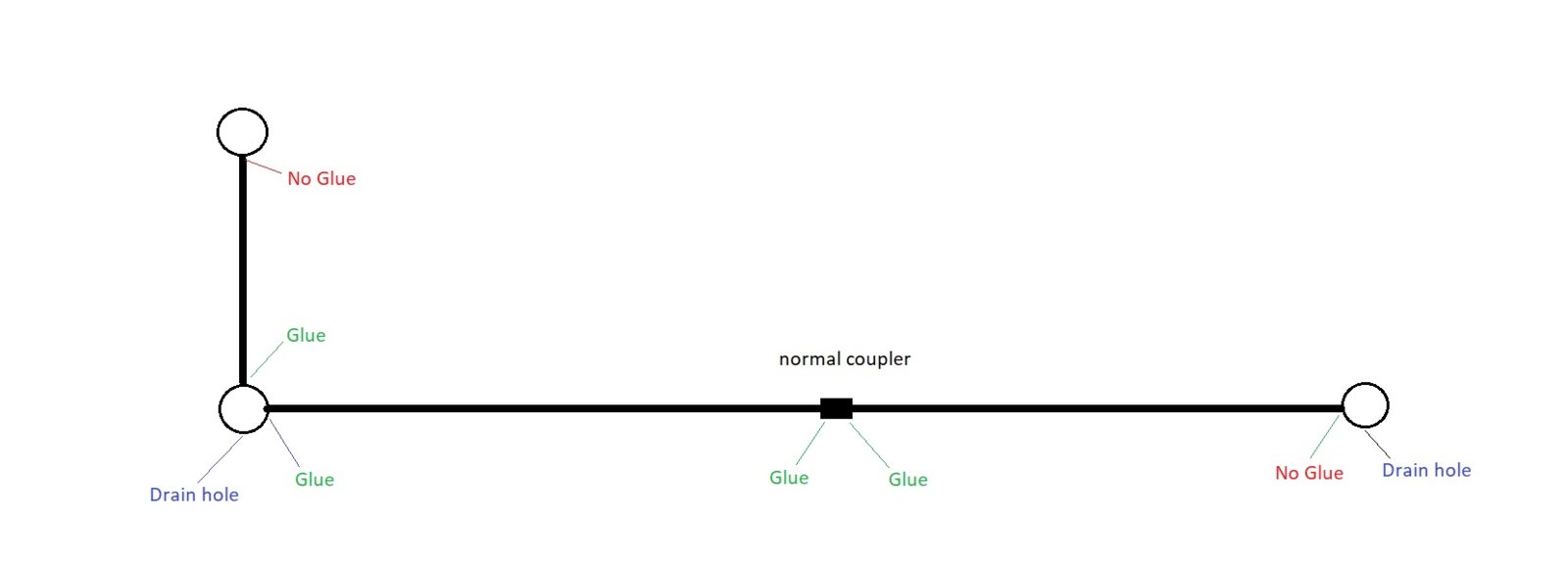

On the topic of 'to glue or not to glue', to me it's a case of glueing some joins and not others, so you're not just allowing for expansion, you're thinking about where it will happen and by how much.

For example, if I was putting up a PVC conduit run that went down 1.5m, then to the right 6m, I would install it like this... (saddles omitted!)

With the join on the right into the terminal box, if it was was a very hot day, I'd shove the tube all the way in. If it was cold, about half way in.

With a 6 metre run and allowing for a 30° temperature change throughout the year, it will expand/contract by 10.8mm. Seeing as the couplers and terminal boxes allow 20mm of tube entry, everything will be fine. I would never do a 9m run without a through box in the middle somewhere, just to cover the rare days when it's outside of my -5 to 25° 'estimate'.

The worst conduit jobs I've seen are when the PVC has shrunk too much and popped out of a join, then when it expands in the summer, that's when the trouble starts and it goes wavy and looks awful! Putting some thought into the installation solves all that.

Gaz

For example, if I was putting up a PVC conduit run that went down 1.5m, then to the right 6m, I would install it like this... (saddles omitted!)

With the join on the right into the terminal box, if it was was a very hot day, I'd shove the tube all the way in. If it was cold, about half way in.

With a 6 metre run and allowing for a 30° temperature change throughout the year, it will expand/contract by 10.8mm. Seeing as the couplers and terminal boxes allow 20mm of tube entry, everything will be fine. I would never do a 9m run without a through box in the middle somewhere, just to cover the rare days when it's outside of my -5 to 25° 'estimate'.

The worst conduit jobs I've seen are when the PVC has shrunk too much and popped out of a join, then when it expands in the summer, that's when the trouble starts and it goes wavy and looks awful! Putting some thought into the installation solves all that.

Gaz

A normal coupler really isn't suitable for that purpose. That's why expansion couplers are manufactured.On the topic of 'to glue or not to glue', to me it's a case of glueing some joins and not others, so you're not just allowing for expansion, you're thinking about where it will happen and by how much.

For example, if I was putting up a PVC conduit run that went down 1.5m, then to the right 6m, I would install it like this... (saddles omitted!)

View attachment 140450

With the join on the right into the terminal box, if it was was a very hot day, I'd shove the tube all the way in. If it was cold, about half way in.

With a 6 metre run and allowing for a 30° temperature change throughout the year, it will expand/contract by 10.8mm. Seeing as the couplers and terminal boxes allow 20mm of tube entry, everything will be fine. I would never do a 9m run without a through box in the middle somewhere, just to cover the rare days when it's outside of my -5 to 25° 'estimate'.

The worst conduit jobs I've seen are when the PVC has shrunk too much and popped out of a join, then when it expands in the summer, that's when the trouble starts and it goes wavy and looks awful! Putting some thought into the installation solves all that.

Gaz

Most of what you say makes fairly good sense. However, I would point out that, even in the UK, a black object in direct sunlight can get very much hotter than 25°. Just this afternoon, the (black) wing mirror of my car (not to mention the steering wheel) were far too hot to touch - hence probably at least 50°-60°..... just to cover the rare days when it's outside of my -5 to 25° 'estimate'.

Kind Regards, John

- Joined

- 28 Jul 2014

- Messages

- 1,969

- Reaction score

- 566

- Country

a black object in direct sunlight can get very much hotter than 25°

Too much expansion temporarily will be taken up by the elasticity of the PVC, it will compress and recover, as long as the saddle spacing is close. I usually use 'every 3 bricks' for 25mm conduit, which works out to about 75cm spacing. For 20mm, that looks a bit long, so more like 'every 2½ bricks', but with avoiding the mortar at all costs! i.e....

Too much contraction is the real problem, as it can cause an end to pop out and get stuck when expansion re-occurs. I have seen many installations where there is no glue on any joint and none of the joints were fully pushed in, every join seems to have been left loose, 'to allow for expansion'. The joints then all slide about wherever they want until the tube pops out of a coupler for example. Now that that end is now crooked because it has drooped, thermal expansion wont be taken up by the elasticity of the PVC, because it's not being held rigidly, it makes a nice sine wave between the saddles!

Last edited:

- Joined

- 28 Jul 2014

- Messages

- 1,969

- Reaction score

- 566

- Country

A normal coupler really isn't suitable for that purpose.

Of course it is. With my drawn example above, lets say we installed it in the shade (thanks JohnW2!!

For our 6m run to contract by 20mm in the winter and therefore fall out of the coupler it would need a temperature drop of...

20mm/(6000mm*0.00006)=55.55555°

I.e it would need to go below -30°C to fall out.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

O

- Replies

- 3

- Views

- 4K

- Replies

- 9

- Views

- 16K