Greetings all.

I'm after a bit of advice as we have an issue with our HW kettling and on closer inspection the wiring on our 2-port Valves looks a little suspect to my untrained eye.

Background:

The house was built in 2001 and has an 'S' CH/HW System installed. If the HW is on and the CH is not, the HW in the pipes overheats and starts to kettle. We have Drayton ZA6 valves fitted and I know they have an issue where the microswitch can stick and as the original 20 yr old unit was still fitted to the HW side (CH had been replaced at some point) I swapped it out for a new one. I also replaced the Cylinder Stat in case that wasn't switching the pump and boiler off when up to temp.

Now the problem still occurs. The only workaround is to have the CH and HW on at the same time to enable the additional heat to dissipate in the CH circuit.

Wiring Issue:

The cylinder stat does cut power to the valve causing it to close but I've had a closer look at the wiring (still original configuration as the old cables were routed out to make connections to the new cables in a separate junction box). Both HW and CH valves appear to be connected differently to how Drayton instruct.

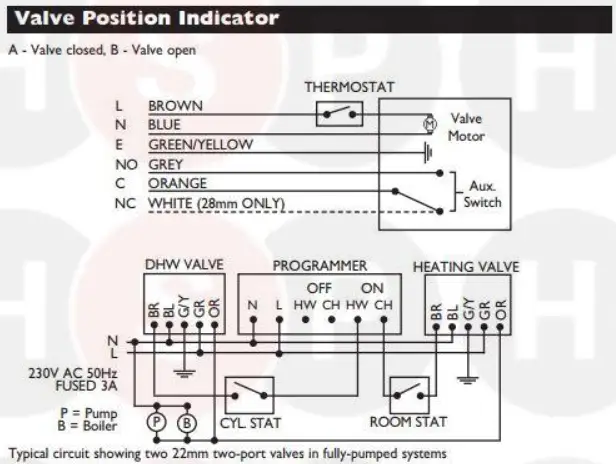

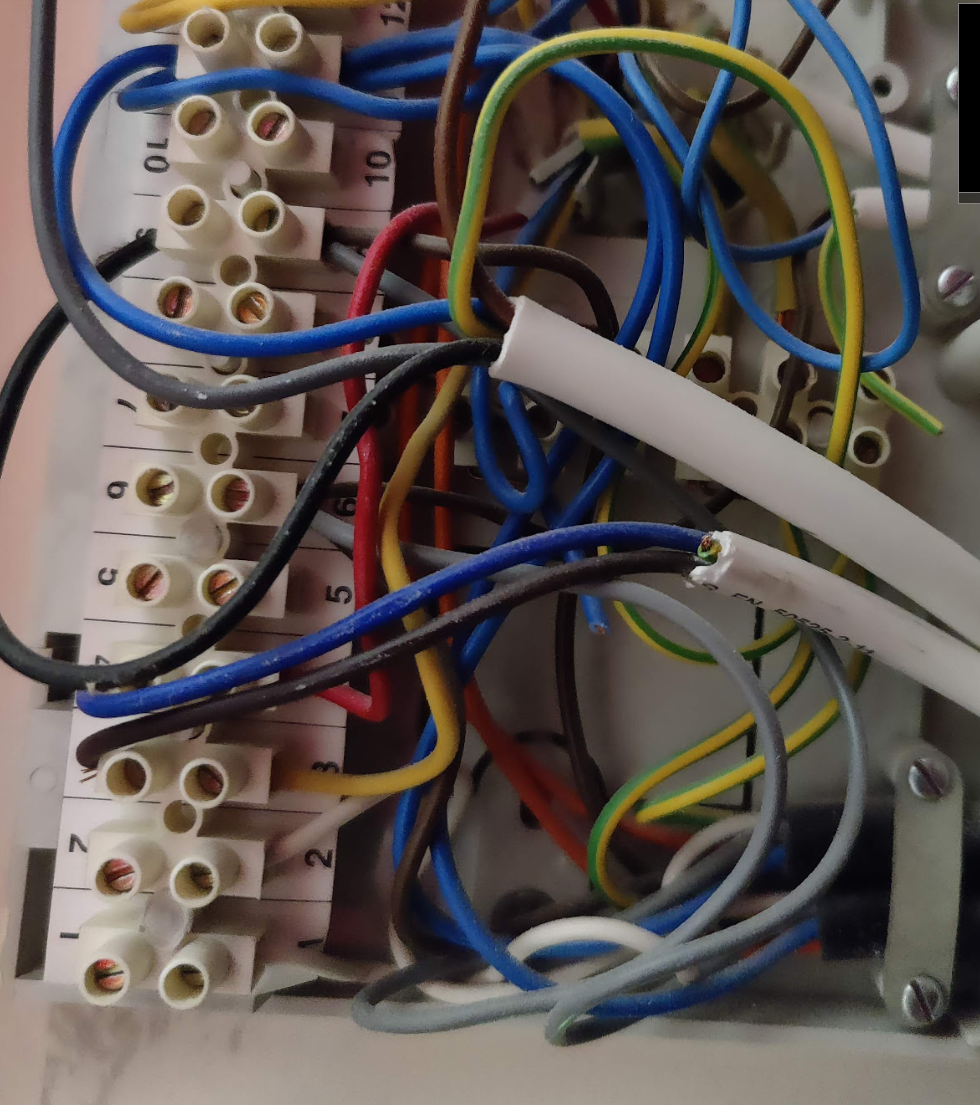

CH Valve - On our system both the Brown and Grey wires are connected together with the Heating Call for Heat from the Nest Thermostat Heatlink. The drawing above shows that the grey wire should be connected to permanent Live. See Terminal 9 in the photo below.

HW Valve - On our system both the Brown and Grey wires are connected together with the Cylinder Stat. The drawing above again shows that the Grey wire should be connected to permanent Live. See Terminal 6 in the photo below.

From top to bottom the cables are:

Pump

Cylinder Stat

Nest Thermostat Heatlink (N, L, 1 thru 6)

Nest Thermostst Heatlink (T1 and T2)

HW Zone Valve

CH Zone Valve

The way I see it is wiring the valves this way bypasses the microswitch by using the stats to cut power to the boiler and pump. Am I right or have I got this completely wrong? And could this configuration cause the pump and boiler to actually stay on irrespective of valve position?

Many thanks in advance.

I'm after a bit of advice as we have an issue with our HW kettling and on closer inspection the wiring on our 2-port Valves looks a little suspect to my untrained eye.

Background:

The house was built in 2001 and has an 'S' CH/HW System installed. If the HW is on and the CH is not, the HW in the pipes overheats and starts to kettle. We have Drayton ZA6 valves fitted and I know they have an issue where the microswitch can stick and as the original 20 yr old unit was still fitted to the HW side (CH had been replaced at some point) I swapped it out for a new one. I also replaced the Cylinder Stat in case that wasn't switching the pump and boiler off when up to temp.

Now the problem still occurs. The only workaround is to have the CH and HW on at the same time to enable the additional heat to dissipate in the CH circuit.

Wiring Issue:

The cylinder stat does cut power to the valve causing it to close but I've had a closer look at the wiring (still original configuration as the old cables were routed out to make connections to the new cables in a separate junction box). Both HW and CH valves appear to be connected differently to how Drayton instruct.

CH Valve - On our system both the Brown and Grey wires are connected together with the Heating Call for Heat from the Nest Thermostat Heatlink. The drawing above shows that the grey wire should be connected to permanent Live. See Terminal 9 in the photo below.

HW Valve - On our system both the Brown and Grey wires are connected together with the Cylinder Stat. The drawing above again shows that the Grey wire should be connected to permanent Live. See Terminal 6 in the photo below.

From top to bottom the cables are:

Pump

Cylinder Stat

Nest Thermostat Heatlink (N, L, 1 thru 6)

Nest Thermostst Heatlink (T1 and T2)

HW Zone Valve

CH Zone Valve

The way I see it is wiring the valves this way bypasses the microswitch by using the stats to cut power to the boiler and pump. Am I right or have I got this completely wrong? And could this configuration cause the pump and boiler to actually stay on irrespective of valve position?

Many thanks in advance.