- Joined

- 24 Jul 2023

- Messages

- 110

- Reaction score

- 10

- Country

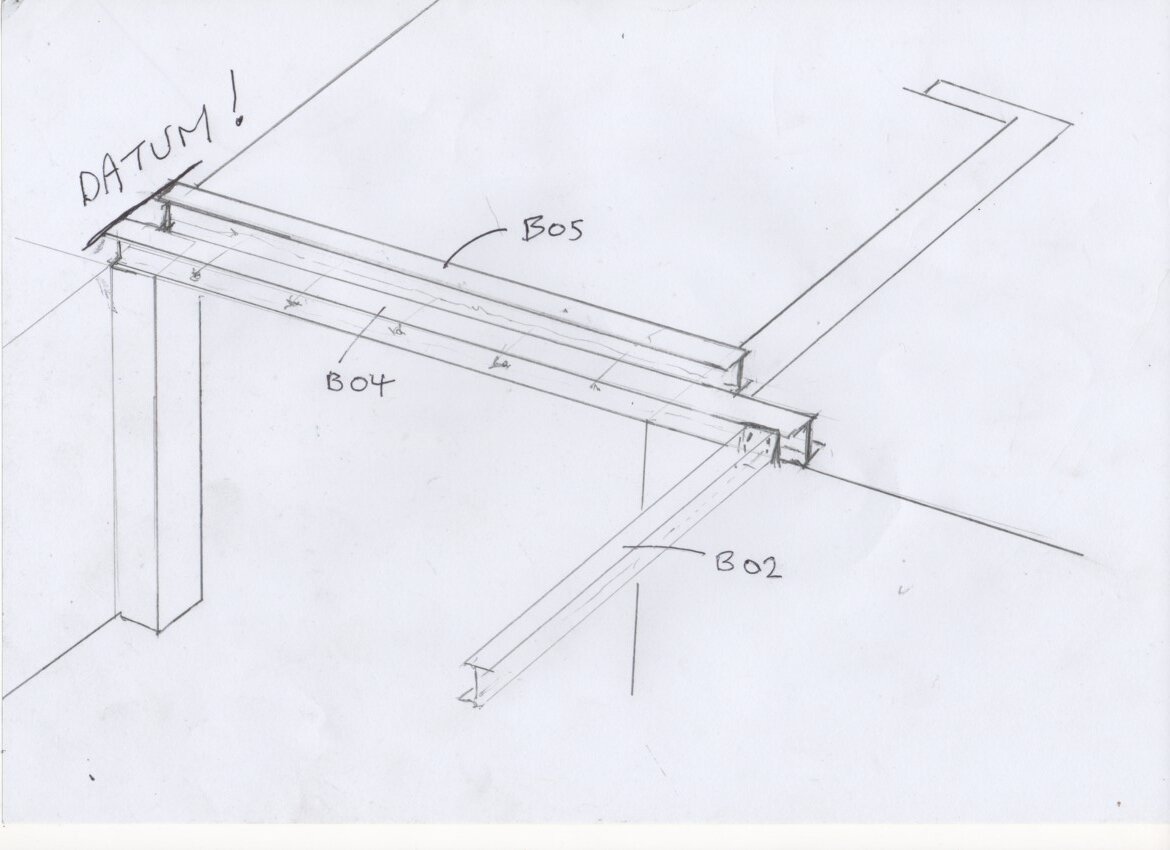

The first beam has been in a while it's got a plate welded with the holes for the bolts. Then needs another one attached to form a T shape. The first one is nice and plumb and I assume the second one will be square and true but it occurred to me that once it's screwed tight it might be off slightly and not giving a perfect 90 degrees.

My question is, is there any way of adjusting it slightly if that's the case? Possible where the washers go?

My question is, is there any way of adjusting it slightly if that's the case? Possible where the washers go?