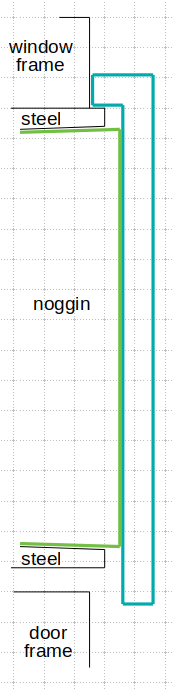

The outside of my unusual conservatory needs finishing. Above the doors is a 152 mm steel beam (approx. 4.3 m), which has the grey factory coating. On top of the steel are aluminium window frames - with no sill - in RAL 7016. They are only a few mm behind the front of the flange of the steel, like the aluminium door frames underneath. There will be an external blind on the windows.

The beam is supported by a steel post at either end. There will eventually be decking outside.

An additional complication is that I would like to fit an awning. One of the many things my architect failed to take account of is that the doors open outwards, so this will have virtually no slope on it (rain sensor required). It would extend across the house to the left, with two of its three brackets being bolted to the web and at least the middle one having to be spaced off, as the house is proud of the steel by about 40mm at that height.

One possibility to protect the steel is to use RAL 7016 uPVC fascia capping. A strip of this could be installed in front of the beam, upside down, with its lip trimmed and sealed against the window frames. It would be held in place with plastic-headed nails driven into treated noggins wedged in the steel, and would be wide enough to overhang the bottom flange slightly without fouling the doors.

The lip would be left long enough to leave a small gap in front of the lower flange, which would allow some air to get to the noggins - I'm nervous about sealing them in completely. The gaps between them could be filled with expanding foam or insulation sheet offcuts.

Similar capping could be used to protect the posts, and the gap would allow this to be slipped underneath.

I am guessing the pressure of the mounting brackets for the awning would crush the capping, so instead I'm thinking of slipping a piece of thick alloy tube/drilled dowel over each mounting bolt/stud (four per bracket), which would be cut to space the brackets off the surface. It will be easy to drill the capping for this, and easy to seal around.

Is this plan sensible, bonkers, or somewhere in between?

Alternatives:

The beam is supported by a steel post at either end. There will eventually be decking outside.

An additional complication is that I would like to fit an awning. One of the many things my architect failed to take account of is that the doors open outwards, so this will have virtually no slope on it (rain sensor required). It would extend across the house to the left, with two of its three brackets being bolted to the web and at least the middle one having to be spaced off, as the house is proud of the steel by about 40mm at that height.

One possibility to protect the steel is to use RAL 7016 uPVC fascia capping. A strip of this could be installed in front of the beam, upside down, with its lip trimmed and sealed against the window frames. It would be held in place with plastic-headed nails driven into treated noggins wedged in the steel, and would be wide enough to overhang the bottom flange slightly without fouling the doors.

The lip would be left long enough to leave a small gap in front of the lower flange, which would allow some air to get to the noggins - I'm nervous about sealing them in completely. The gaps between them could be filled with expanding foam or insulation sheet offcuts.

Similar capping could be used to protect the posts, and the gap would allow this to be slipped underneath.

I am guessing the pressure of the mounting brackets for the awning would crush the capping, so instead I'm thinking of slipping a piece of thick alloy tube/drilled dowel over each mounting bolt/stud (four per bracket), which would be cut to space the brackets off the surface. It will be easy to drill the capping for this, and easy to seal around.

Is this plan sensible, bonkers, or somewhere in between?

Alternatives:

- Use aluminium cladding. This could either be a flat sheet overlapped with a shallow Z-section at the top, or done in one piece. I think that this is going to be expensive, especially if powder-coated. It has the advantage that it can't be crushed, but the bracket would then need a noggin to support it at the back, and something weatherproof such as the aforementioned tube to space it off the front.

- Leave the steel unclad and paint it. What would I use, given that it's already got that grey primer or whatever on it, but this has failed in places?

- Any other ideas? (Knocking it down and starting again is not an option.

)

)

Last edited: