- Joined

- 27 Sep 2004

- Messages

- 1,300

- Reaction score

- 83

- Country

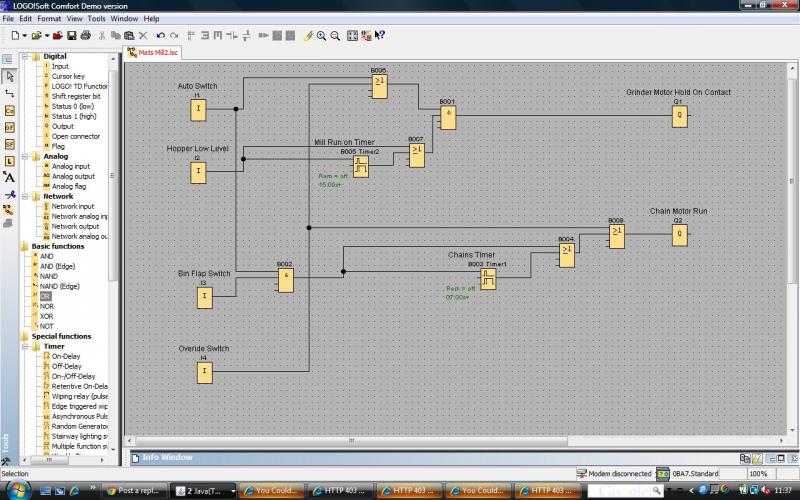

I need a PLC for control of a mill. I was thinking of using a Siemens Logo, I think (havn't fully worked it all out yet) but 4 I/O should be enough and LOGO's come in this for a reasonable price. My problem is this...

I havn't done much PLC work since I left college, (8 years ago!) and even then it wasn't studied that much so a may be a bit rusty!

Are LOGO's capable of having timers programmed?

Is the PC software ladder logic and is it cheap? (I know you can program them on the screen, but figured it would be easier using PC software!)

Anyone have any other suggestions as a good alternative brand and any help appreciated!?

Thanks

Chris

I havn't done much PLC work since I left college, (8 years ago!) and even then it wasn't studied that much so a may be a bit rusty!

Are LOGO's capable of having timers programmed?

Is the PC software ladder logic and is it cheap? (I know you can program them on the screen, but figured it would be easier using PC software!)

Anyone have any other suggestions as a good alternative brand and any help appreciated!?

Thanks

Chris