6K1 is an "old style" (and simple) electronic component called a relay.

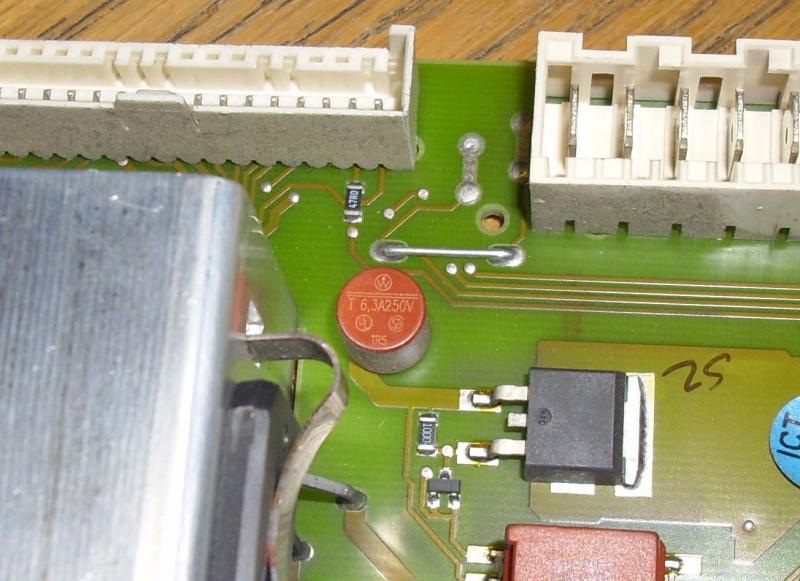

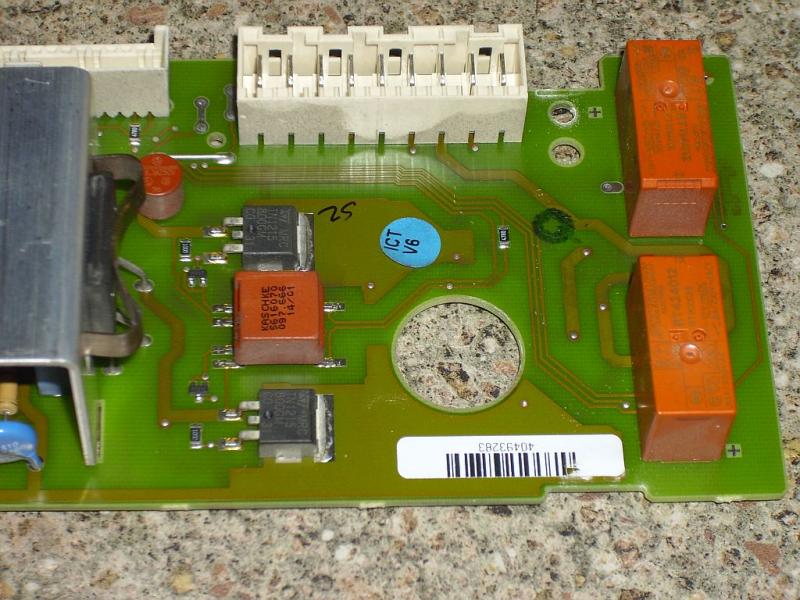

It's the top LHS orange rectangular device in this pic: http://i220.photobucket.com/albums/dd257/harrykiri/MieleW828RelayBoard.jpg

It's used to reverse the direction of rotation of the drum during the wash/rinse cycles. It does this by reversing the polarity of the voltage applied to the DC drum motor. The associated cct. board (EDPW) watches how long the drum rotates in one direction, then sends a signal to 6K1 (in the EL200D) to tell it to reverse the drum direction. 6K1 is like two switches that operate at the same time. In this case, the contacts on one of the switches overheated and melted together, which resulted in no voltage sent to the drum motor, together with a near short circuit being connected to the power supply. I was very lucky the SCR's didn't fail as well - an outcome normally expected in these circumstances.

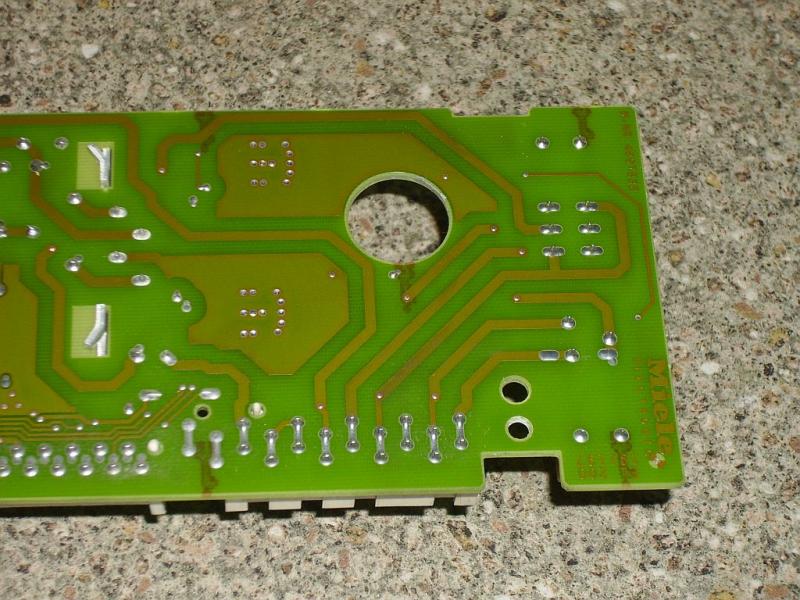

Unfortunately, the technique to remove the relay from the PCB requires a fair bit of skill in "desoldering", or tracks on the board can be badly damaged. However that pales into insignificance, compared to the skill required to remove the SCR's (in this case in the form of SMD's or "surface mounted devices"). I was very relieved when the SCR's proved to be OK as I have neither the skill nor the special tools to replace them. I guess I'd have gone out and purchased an SMD removal kit ... although unlikely to use it again any time soon.

Yes, the time taken to pursue this to the end was more than I ever expected, but I was given renewed purpose by the appearance of more posters following Beano & I. Apart from saving my own machine from landfill (I was about to scrap the Miele, due to the extreme cost of parts), others will find this site and thread, so the many hours spent developing the partial circuit diagram hasn't been wasted. My only regret is that the circuit came too late to benefit everyone who contributed in the last couple of months

It's the top LHS orange rectangular device in this pic: http://i220.photobucket.com/albums/dd257/harrykiri/MieleW828RelayBoard.jpg

It's used to reverse the direction of rotation of the drum during the wash/rinse cycles. It does this by reversing the polarity of the voltage applied to the DC drum motor. The associated cct. board (EDPW) watches how long the drum rotates in one direction, then sends a signal to 6K1 (in the EL200D) to tell it to reverse the drum direction. 6K1 is like two switches that operate at the same time. In this case, the contacts on one of the switches overheated and melted together, which resulted in no voltage sent to the drum motor, together with a near short circuit being connected to the power supply. I was very lucky the SCR's didn't fail as well - an outcome normally expected in these circumstances.

Unfortunately, the technique to remove the relay from the PCB requires a fair bit of skill in "desoldering", or tracks on the board can be badly damaged. However that pales into insignificance, compared to the skill required to remove the SCR's (in this case in the form of SMD's or "surface mounted devices"). I was very relieved when the SCR's proved to be OK as I have neither the skill nor the special tools to replace them. I guess I'd have gone out and purchased an SMD removal kit ... although unlikely to use it again any time soon.

Yes, the time taken to pursue this to the end was more than I ever expected, but I was given renewed purpose by the appearance of more posters following Beano & I. Apart from saving my own machine from landfill (I was about to scrap the Miele, due to the extreme cost of parts), others will find this site and thread, so the many hours spent developing the partial circuit diagram hasn't been wasted. My only regret is that the circuit came too late to benefit everyone who contributed in the last couple of months