quote="Spark123";p="1140108"][

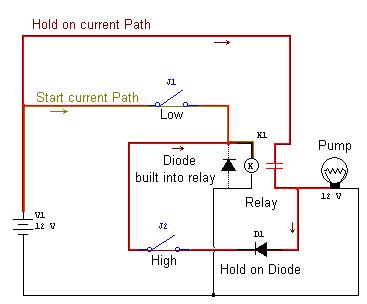

No, the current cannot flow in the direction you have indicated on the diagram as the diode prevents this.

If you missed the diode out of the wiring then yes, you could overload the switch. As I have said on a number of occasions now, you need to fit the diodes. As you look at a diode the white line corresponds with the line across the diode on the diagram.

Or as Ban-all-sheds is heading for, double poled devices will work too.[/quote]

Yes the diodes wear in place

A diode is not there to reduce the current it is there to allow an electric current to pass in one direction and to block the current in the opposite direction

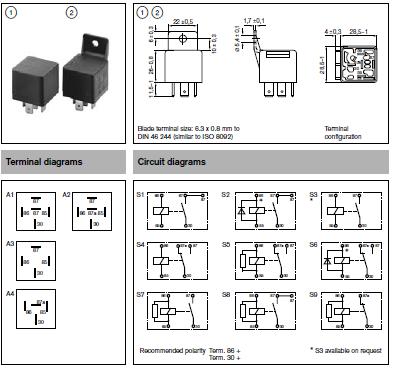

It’s a 4 pin standard 20/30 amp car relay as seen in the original schematic

And a 5 pin would not helf since 87a is just a common and not for reducing current

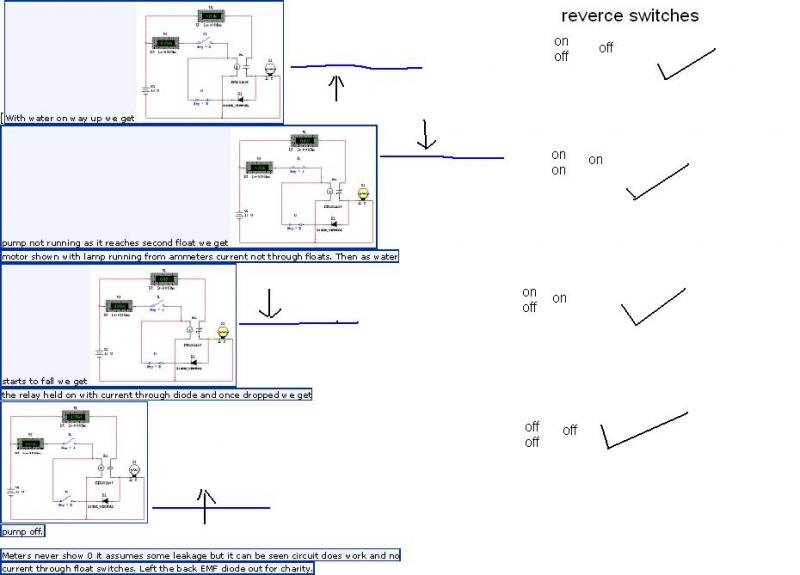

Well I could not see anything wrong with original diagram. Two thoughts spring to mind.

1) Diode had gone short circuit.

2) Been replaced with wrong relay. I think it was ford who used one corner of coil and other corner for contacts. The numbers remained the same but physical position changed and I have seen a few people caught out with it.

I did look on

Durite site as they use to have all the different types listed in their catalogue but seems they still don't do an on line version.

Dose not matter which way the pins are placed on the relay just as long as you follow the diagram on the rely with relation to numbers

Other wise the sequence would not work

And the sequence of the original diagram worked perfectly when I used hard core standard switches

The easiest way of getting round this is to use 15 map rated float switches

And if anyone knows wear I can get them if it meant paying 30 quid for them then id have it

Coz I know it would do the job

Had a look at some tilt switches coz you could put that into a ball float and make a float switch

But again they wear only Mickey Mouse 300ml 1amp max

maybe not longer made was a long time ago I did auto work. There were some relays used on ford which had different pin config but can't find any now.

maybe not longer made was a long time ago I did auto work. There were some relays used on ford which had different pin config but can't find any now.