Do you know what your water pressure is downstream of the PRV, has it been checked physically checked? It's definitely an EV issue. After a bit of thought, I believe it's the baffle in the throat of the EV that causes it, and it's due to the movement of pressure from the EV to the pipework when the HW tap is opened. Balancing the pressure up between the EV pre-charge and the Water pressure minimises the movement of that pressure, may need a bit of fine tuning

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Noise from unvented hot water system

- Thread starter George Isles

- Start date

- Joined

- 11 Apr 2022

- Messages

- 16

- Reaction score

- 0

- Country

Downstream pressure is regulated by the accumleator tank which is set to 2bar….are you thinking drop the precharge in the EV to 2bar? I See the logic…

As said the vessel pre charge should be set to site conditions, if you have 2 bar static pressure downstream of the PRV your pre charge would need to be set to 1.8 bar if you leave the gauge on you will set it rise to 2.0bar. The diaphragm closes off the outlet if its too high and farts as it releases the pressure built up when heated.

hope this might help Mark

hope this might help Mark

I would prefer it 0.5bar lower as the diaphragm is just that little bit further away and less chance of bottoming hard up against the water end and if the PRV doesn't maintain its say 2bar setting when large volumes of hot water and balanced cold are being drawn down, the diaphragm not bottoming out also helps to prevent water hammer (so we are told).

Example: Say 250L HW cylinder with a 24L EV and EV with a pre charge pressure of 1.8bar & PRV at 2bar as suggested above. With a cold cylinder there will be 1.6L of water in the EV, 250L of water will expand by 4.1L in rising from say 15C to 60C so there will now be 5.7L in the EV (1.6+4.1) and the cylinder pressure will have risen to 2.7bar, as soon as 4.1L of HW is drawn off then the pressure will return to 2.0 bar and there will still be 1.6L acting as a buffer in the EV.

If the EV is only pre charged to 1.5bar and with the same 2bar PRV setting there will now be 4.0L of water in the EV, 250L of water will again expand by 4.1L in rising from say 15C to 60C so there will now be 8.1L in the EV (4.0+4.1) and the cylinder pressure will have risen to 2.8bar, as soon as 4.1L of HW is drawn off then the pressure will return to 2.0 bar and there will now be 4.0L acting as a buffer in the EV. So a bit more breathing space with only a tiny rise in cylinder pressure when hot. (Assuming EV properly sized). In my time, when testing a EV we always ran the diaphragm from one end of the EV to the other, we would release all the air end pressure and pressurize the water end to 2bar, then reduce/vent the water end and pressurize the air end to 2bar and then set its pre charge pressure, maybe a bit of overkill but it ensured that the diaphragm wasn't sticking to the sides of the EV.

Example: Say 250L HW cylinder with a 24L EV and EV with a pre charge pressure of 1.8bar & PRV at 2bar as suggested above. With a cold cylinder there will be 1.6L of water in the EV, 250L of water will expand by 4.1L in rising from say 15C to 60C so there will now be 5.7L in the EV (1.6+4.1) and the cylinder pressure will have risen to 2.7bar, as soon as 4.1L of HW is drawn off then the pressure will return to 2.0 bar and there will still be 1.6L acting as a buffer in the EV.

If the EV is only pre charged to 1.5bar and with the same 2bar PRV setting there will now be 4.0L of water in the EV, 250L of water will again expand by 4.1L in rising from say 15C to 60C so there will now be 8.1L in the EV (4.0+4.1) and the cylinder pressure will have risen to 2.8bar, as soon as 4.1L of HW is drawn off then the pressure will return to 2.0 bar and there will now be 4.0L acting as a buffer in the EV. So a bit more breathing space with only a tiny rise in cylinder pressure when hot. (Assuming EV properly sized). In my time, when testing a EV we always ran the diaphragm from one end of the EV to the other, we would release all the air end pressure and pressurize the water end to 2bar, then reduce/vent the water end and pressurize the air end to 2bar and then set its pre charge pressure, maybe a bit of overkill but it ensured that the diaphragm wasn't sticking to the sides of the EV.

Last edited:

- Joined

- 11 Apr 2022

- Messages

- 16

- Reaction score

- 0

- Country

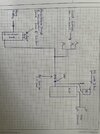

Sounds like I need to get the plumber to tinker with the pressure balance. He was telling me everything was balanced as I have an accumulator tank with a mainsboost pump, the pump is set to maintain a pressure of 2bar…..see diagram below.

Attachments

Re the accumulator, normally if its a pumped accumulator, its first drained down and pre charged (like a EV) to 2bar (whatever the minimum pressure required) the pump should then charge/pump it to say 3.5bar to 4bar and then cut out, the accumulator will then give between 33L and 40L for every 100L of accumulator capacity in falling to 2bar.

What is the accumulator volume and do you ever see the pump at any other pressure other than 2.0bar.

What is the accumulator volume and do you ever see the pump at any other pressure other than 2.0bar.

- Joined

- 11 Apr 2022

- Messages

- 16

- Reaction score

- 0

- Country

pump pressure is set to 2bar with a 0.2bar differential, tried increasing the pressure to 3bar but made no difference. It’s 250L tank with a 1.4bar precharge. Pressure rarely fluctuates

If you are happy with 2/2.2 bar then grand as the accumulator will supply 12.5L while the pressure is falling from 2.2bar to 2.0bar and should mean that the pump would remain off for ~ 30 secs if the demand is 25LPM.

So a EV pre charge of 1.8bar should be spot on and the EV shouldn't be the cause of your problem at that setting IMO. You might also note the HW cylinder and the EV volumes sometime.

I see in post #29 that the EV is pre charged to 3bar, this means that a 25L EV will rise to 3.8bar when heated to 60C (assuming 250L HW cylinder) with 4.1L in the EV and will fall to 3bar then 2bar once that 4.1L is used up with the diaphragm hard up against the water end, not ideal, only approx say 175 litres might be reheated with expansion of ~ 2.0L so when you run the shower it will take ~ 8 secs for the diaphragm to move hard up against the water end.

Edit. Up early as just brought a neighbor to the Airport.

You have a combination valve with its PRV presumably set to 2.0bar but you are supplying this at 2/2.2bar from the accumulator, this may result in erratic control as a PRV needs ~ 1bar differential to work properly. You might consider removing the combination valve and just install a NRV with the 6bar expansion valve. Also presume that the cold water PRV (if installed) is working under the same conditions, if so, maybe just remove that also?, food for thought anyway.

So a EV pre charge of 1.8bar should be spot on and the EV shouldn't be the cause of your problem at that setting IMO. You might also note the HW cylinder and the EV volumes sometime.

I see in post #29 that the EV is pre charged to 3bar, this means that a 25L EV will rise to 3.8bar when heated to 60C (assuming 250L HW cylinder) with 4.1L in the EV and will fall to 3bar then 2bar once that 4.1L is used up with the diaphragm hard up against the water end, not ideal, only approx say 175 litres might be reheated with expansion of ~ 2.0L so when you run the shower it will take ~ 8 secs for the diaphragm to move hard up against the water end.

Edit. Up early as just brought a neighbor to the Airport.

You have a combination valve with its PRV presumably set to 2.0bar but you are supplying this at 2/2.2bar from the accumulator, this may result in erratic control as a PRV needs ~ 1bar differential to work properly. You might consider removing the combination valve and just install a NRV with the 6bar expansion valve. Also presume that the cold water PRV (if installed) is working under the same conditions, if so, maybe just remove that also?, food for thought anyway.

Last edited:

- Joined

- 11 Apr 2022

- Messages

- 16

- Reaction score

- 0

- Country

Thanks for all the help, really appreciate it. Combination PRV valve is set to 3 bar and it was the first thing that got changed.

Remove the flexible hose feeding the E.V.

Hardpipe it can reduce it down to 15mm pipe its easier. Few years ago the ariston Classico used to come with a flexible hose it caused chaos in the end they stopped providing them. Installers subsequently Hardpiped them and the noises went away.

Hardpipe it can reduce it down to 15mm pipe its easier. Few years ago the ariston Classico used to come with a flexible hose it caused chaos in the end they stopped providing them. Installers subsequently Hardpiped them and the noises went away.

The PRV is set 3.0bar and the pump/accumulator pressure is 2.0/2.2bar so presumably the PRV is wide open at all times and shouldn't interfere with the flow/pressure.Fault can be either or both the expansion vessel

Bladder has debris on its seat or the pressure reducing valve sticking.

What all ways surprises me is that there is rarely if ever a pressure gauge installed in the HW cylinder which would surely give some info as to system performance.

OK, that's a bit of important information .... you are using a pumped accumulator running @ ~ 2bar. Is it an ST?

As a first, the engineer should be looking to align the pre-charge closer to the input pressure to minimise the differential once the cylinder is fully heated. It sounds like there is a 'sweet spot' with the EV where the pressure release through the EV's baffle is causing a resonance, creating the 'fog horn' noises. You did say that a new PRV/Control group was installed? That would generally rule out the PRV. It may also be an idea to calibrated the PRV closer to the Accumulator's output.

I'm afraid to say though, you could really do with an engineer that is experienced with working with these types of systems, especially when yours is a bit of a hybrid, using an accumulator. This is really UV/EV 1'o'1 and he should be running through all of this stuff. That being said, Gledhill should also be asking the right questions and you shouldn't really have to rely on a forum to get to the bottom of it all for you, not that giving you advice is any issue it's just a long drawn out process for you and it shouldn't need to be.

You really need someone that can work through all of this at one visit, rather than having to come back here once something is tried but doesn't work.

As a first, the engineer should be looking to align the pre-charge closer to the input pressure to minimise the differential once the cylinder is fully heated. It sounds like there is a 'sweet spot' with the EV where the pressure release through the EV's baffle is causing a resonance, creating the 'fog horn' noises. You did say that a new PRV/Control group was installed? That would generally rule out the PRV. It may also be an idea to calibrated the PRV closer to the Accumulator's output.

I'm afraid to say though, you could really do with an engineer that is experienced with working with these types of systems, especially when yours is a bit of a hybrid, using an accumulator. This is really UV/EV 1'o'1 and he should be running through all of this stuff. That being said, Gledhill should also be asking the right questions and you shouldn't really have to rely on a forum to get to the bottom of it all for you, not that giving you advice is any issue it's just a long drawn out process for you and it shouldn't need to be.

You really need someone that can work through all of this at one visit, rather than having to come back here once something is tried but doesn't work.

OK, that's a bit of important information .... you are using a pumped accumulator running @ ~ 2bar. Is it an ST?

As a first, the engineer should be looking to align the pre-charge closer to the input pressure to minimise the differential once the cylinder is fully heated. It sounds like there is a 'sweet spot' with the EV where the pressure release through the EV's baffle is causing a resonance, creating the 'fog horn' noises. You did say that a new PRV/Control group was installed? That would generally rule out the PRV. It may also be an idea to calibrated the PRV closer to the Accumulator's output.

I'm afraid to say though, you could really do with an engineer that is experienced with working with these types of systems, especially when yours is a bit of a hybrid, using an accumulator. This is really UV/EV 1'o'1 and he should be running through all of this stuff. That being said, Gledhill should also be asking the right questions and you shouldn't really have to rely on a forum to get to the bottom of it all for you, not that giving you advice is any issue it's just a long drawn out process for you and it shouldn't need to be.

You really need someone that can work through all of this at one visit, rather than having to come back here once something is tried but doesn't work.

I am quoting OP post #38 which if the Accumulator is actually being used as a accumulator would imply that the cold cylinder pressure could be as low as 1.4bar since the accumulator precharge pressure is set to 1.4bar, the pump is set to 2bar, so should the PRV be set to 1.4bar?, it is presently set to 3bar. 1.4bar would seem low for a unvented HW cylinder.

Also the accumulator is being under utilised as it will only flow 50L in falling from 2bar to 1.4bar. I would expect the pump to be set to ~ 4bar.

Last edited:

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 10

- Views

- 24K

- Replies

- 3

- Views

- 8K

- Replies

- 6

- Views

- 7K

- Replies

- 1

- Views

- 887

- Replies

- 3

- Views

- 2K