A while back there was a post (that I can't find) showing various CU's with all wiring in place.

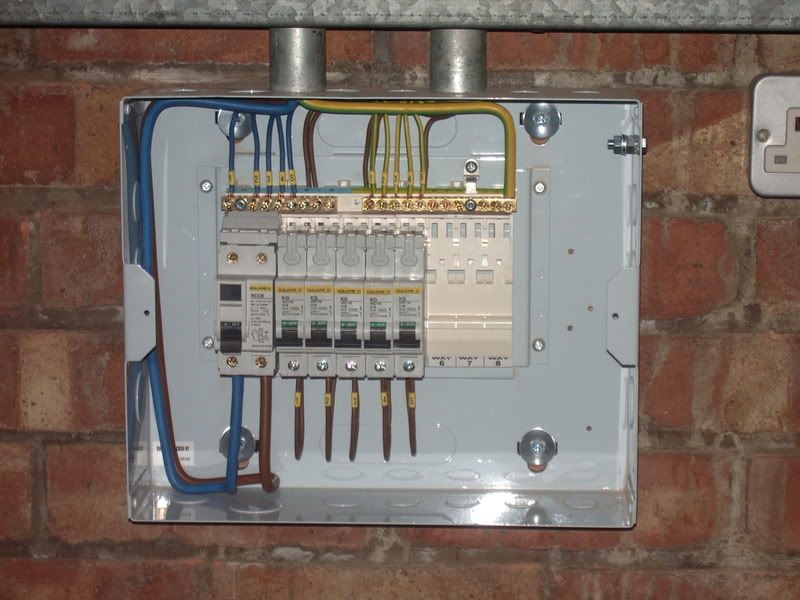

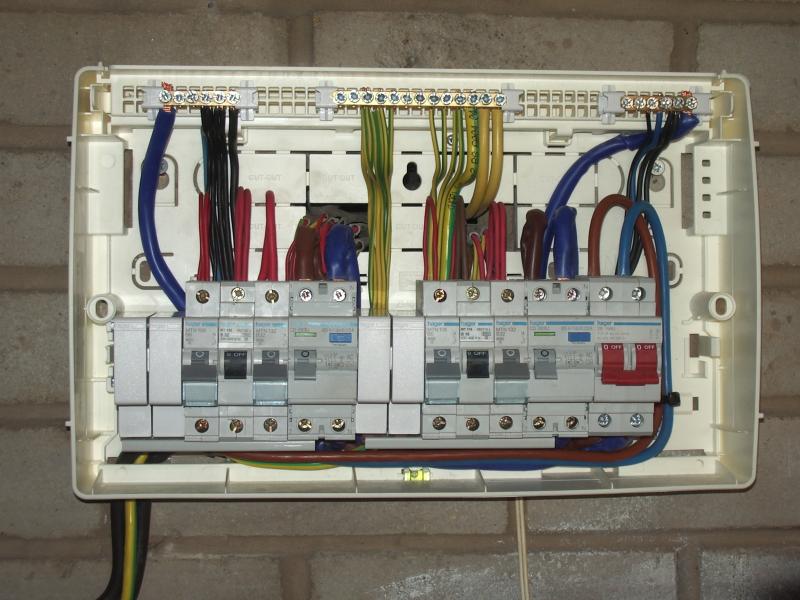

There were a few that had been done very (very) well as in the layout of the LNE's looked really nice, well formed and sexy (in a sparks sort of way ).

).

I've had a hunt about with the search facility and can't find them.

Could someone post links for the old post, or alternatively if you've done some recently please post a picture.

I'm changing my CU on Friday and would just like to take on some tidier methods.

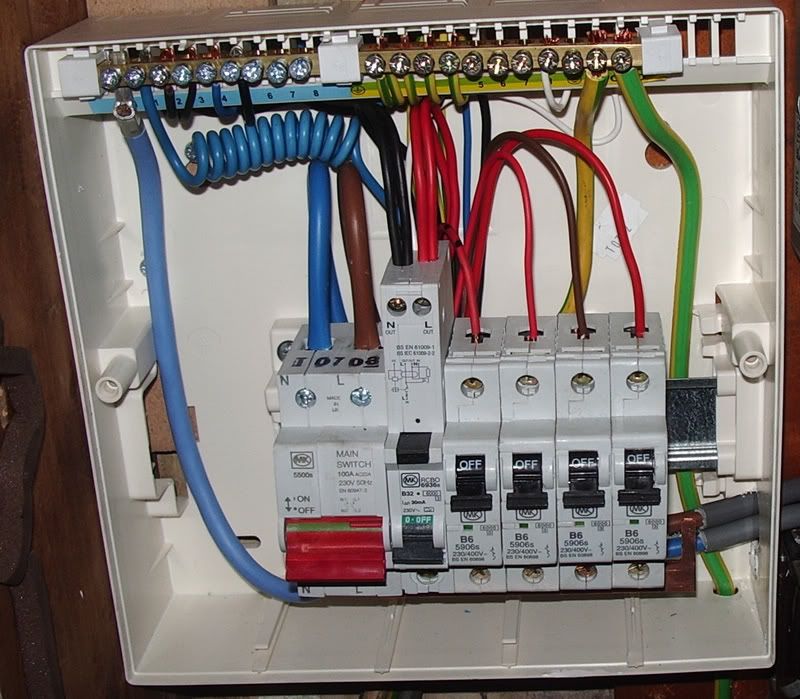

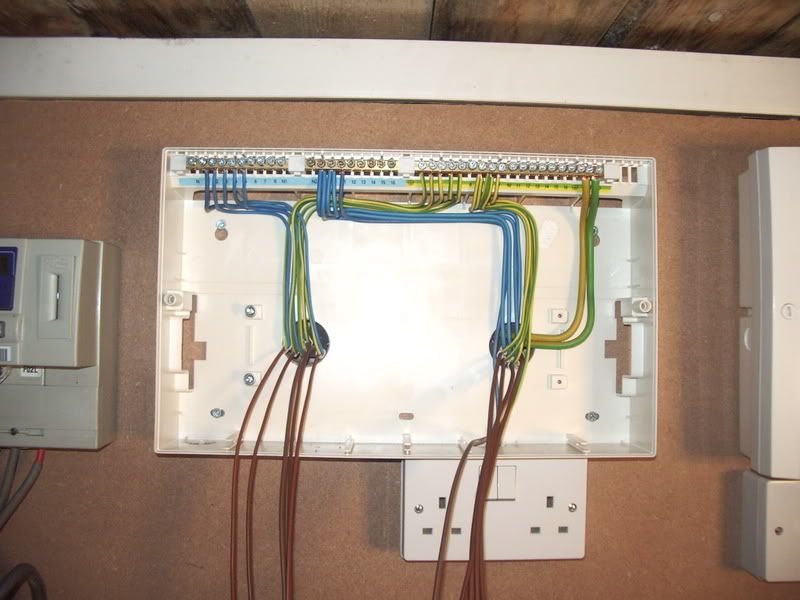

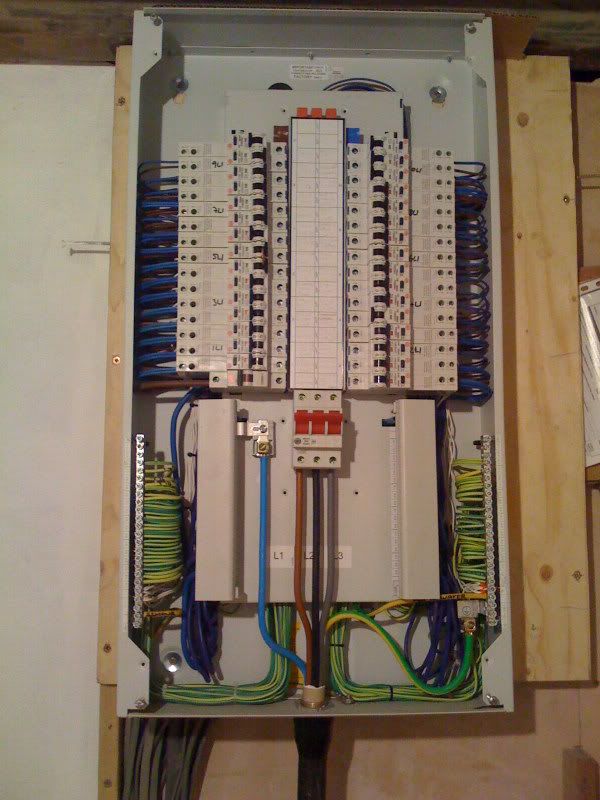

Here's one I did earlier, which I know has room for improvement.

The new board for home has a cavity behind it and the board will be part set in to the wall, this will give me some room to loom the cables to the correct CU position avoiding the sort of mess you see in the picture posted.

Out of interest, since the cavity is behind the board and totally enclosed can I have cables stripped of overall (not core) sheath in the cavity ?

There were a few that had been done very (very) well as in the layout of the LNE's looked really nice, well formed and sexy (in a sparks sort of way

I've had a hunt about with the search facility and can't find them.

Could someone post links for the old post, or alternatively if you've done some recently please post a picture.

I'm changing my CU on Friday and would just like to take on some tidier methods.

Here's one I did earlier, which I know has room for improvement.

The new board for home has a cavity behind it and the board will be part set in to the wall, this will give me some room to loom the cables to the correct CU position avoiding the sort of mess you see in the picture posted.

Out of interest, since the cavity is behind the board and totally enclosed can I have cables stripped of overall (not core) sheath in the cavity ?