- Joined

- 16 Jan 2014

- Messages

- 7

- Reaction score

- 0

- Country

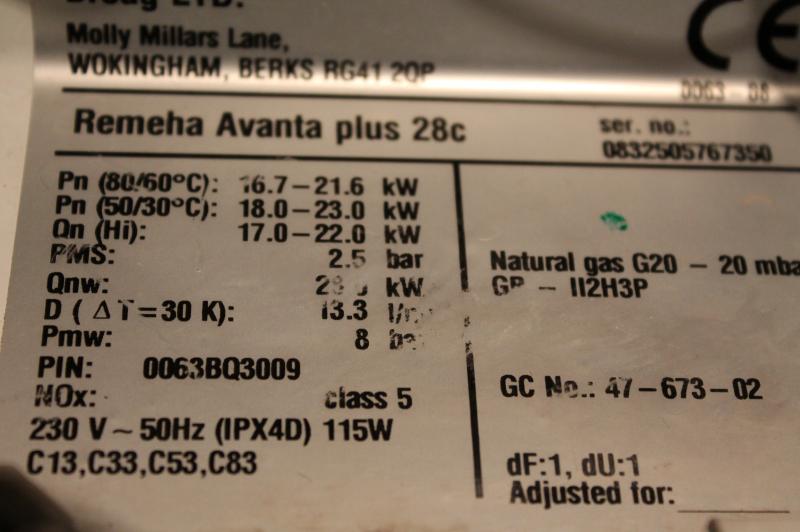

We have a Remeha 28c that is showing a steady 8 on the LCD, (not E8 ) I cannot find any reference to that in the installation manual and Remeha tech will not help us any more because they say that they do not support installations outside the U.K (we are in Spain) despite this particular model being recommended by their salesman specifically because it will work with LPG and there was good technical support.

It was fitted 5 years ago by my brother (retired corgi registered) and checked and passed by Repsol (Spain's British Gas equivalent) for our 5 year certificate. It had a new PCB 1 year ago.

My brother has now put in a new actuator, new internal workings in the 3 way valve and new flow/return sensors, to no avail. It is still showing 8, the pump is running all the time and the boiler is trying to reset itself every 10 minutes or so. Consequently it is switched off until we need hot water.

I have phoned several central heating engineers over here but none will come to look at it because they have to be registered with the company to work on their boilers.

Any help at all would be greatly appreciated.

Julie-Anne.

It was fitted 5 years ago by my brother (retired corgi registered) and checked and passed by Repsol (Spain's British Gas equivalent) for our 5 year certificate. It had a new PCB 1 year ago.

My brother has now put in a new actuator, new internal workings in the 3 way valve and new flow/return sensors, to no avail. It is still showing 8, the pump is running all the time and the boiler is trying to reset itself every 10 minutes or so. Consequently it is switched off until we need hot water.

I have phoned several central heating engineers over here but none will come to look at it because they have to be registered with the company to work on their boilers.

Any help at all would be greatly appreciated.

Julie-Anne.