Hi,

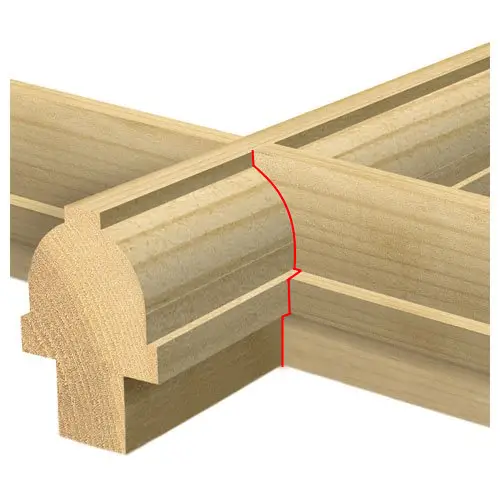

I have a few profiles which I'd like to cut together, much like this:

Although this is a stock image, it is quite indicative of the profiles I'd like to cut as none of them are against a flat surface on which to trace around the profile shown.

How do you go about tracing the profile of one side on to the face of the other in order to cut this out? Does anyone know whether there are any good videos out there - I did try to find some but wasn't sure what the process is called and all I can find are how to scribe on to flat surfaces like walls etc...

Thanks

I have a few profiles which I'd like to cut together, much like this:

Although this is a stock image, it is quite indicative of the profiles I'd like to cut as none of them are against a flat surface on which to trace around the profile shown.

How do you go about tracing the profile of one side on to the face of the other in order to cut this out? Does anyone know whether there are any good videos out there - I did try to find some but wasn't sure what the process is called and all I can find are how to scribe on to flat surfaces like walls etc...

Thanks